PCB waterproofing is a method of protecting PCBs from water and other liquid damage by preventing moisture from entering the interior of the board, thereby protecting electronic components from water. Waterproofing spray for electronics is one of the most common and convenient solutions for this purpose. This can be achieved through coating, encapsulation, waterproof connectors and other methods to ensure that the circuit board operates properly in wet or watery environments and to improve the reliability and durability of the equipment.

1.The importance of PCB waterproofing

Prevent erosion damage

In outdoor, automotive and medical fields, PCBs are vulnerable to water and moisture. Waterproofing spray for electronics plays a critical role in preventing permanent erosion damage, which can result in oxidation reactions, corrosion of copper foils, degradation of solder joints, and component discoloration.

Avoid short circuit

Moisture ingress can lead to short circuits between neighboring copper alignments and tight components. Such short-circuiting can lead to erratic device behavior, sparking and excessive current draw, which can immediately damage the circuit. Waterproof coatings or sprays help mitigate these risks.

Dust protection

Dust and debris buildup on PCBs can interfere with circuit operation over time. A sealed waterproof coating, such as a waterproofing spray for electronics, forms a hermetic surface that prevents fine particles from being deposited on circuit boards and components. This enhances reliability and prolongs service life.

Extended service life

By completely preventing water intrusion, the service life of electronic components can be extended, reducing damage caused by corrosion and loosening. Waterproof treatment not only avoids corrosion and damage to soldered joints caused by oxidation of electronic components, but also reduces the resulting repair and replacement costs.

Easy to clean

As the waterproof treatment makes the PCB can withstand immersion, so cleaning the equipment on the dirt and pollution has become more simple. Sealed electronic devices do not need to be careful to avoid contact with water, simply rinse or submerged in water to quickly wash away any accumulated dirt or organic buildup. For products that must be sterilized occasionally, such as medical equipment, this reduces maintenance time and complexity.

2. Several nano waterproof coating advantages and disadvantages comparison

Currently on the market for electronic products nano waterproof anti-corrosion materials are broadly divided into the following three kinds:

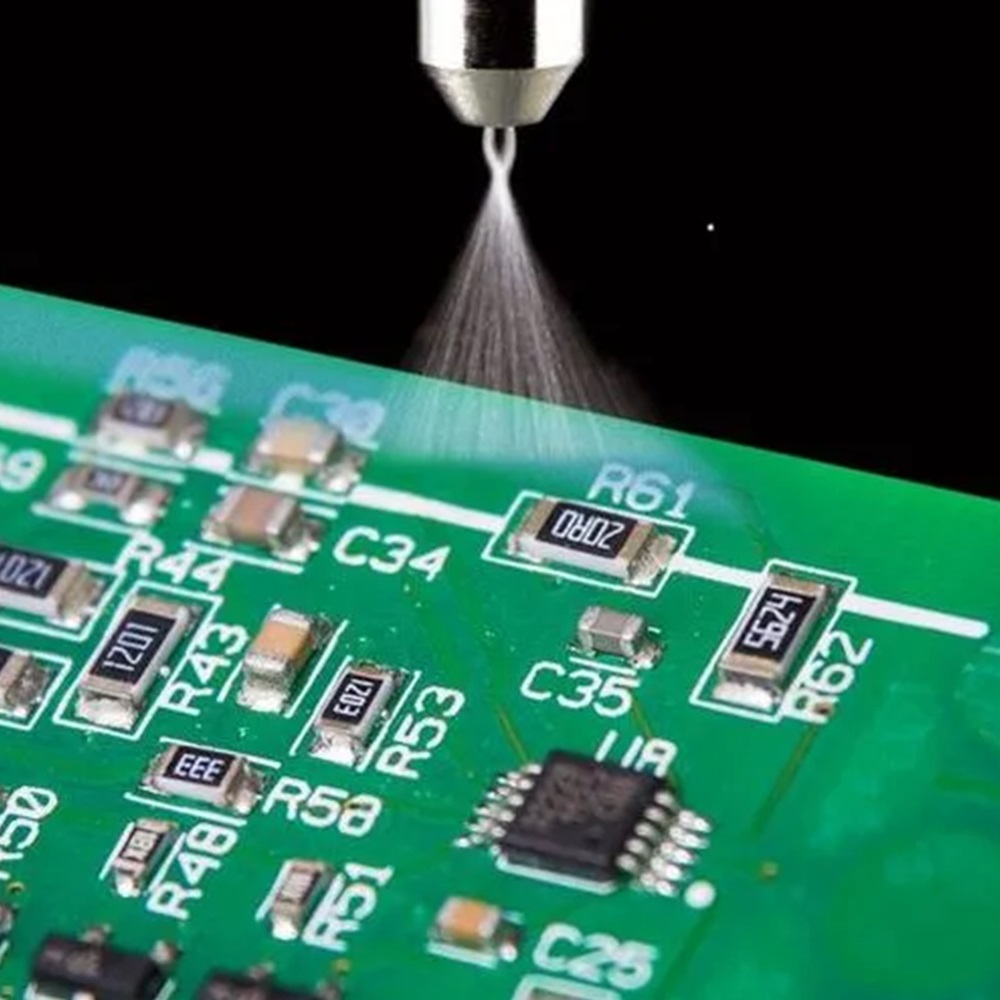

Coating machine vacuum spray waterproof coating

This technology involves applying waterproofing spray for electronics under vacuum conditions. This technology is the use of vacuum coating machine waterproofing agent in vacuum conditions using spray form from the product appearance of the gaps in the spray into the interior of the product, the purpose is still to make the waterproofing agent more extensive to contact the circuit part, but due to the appearance of a variety of products are not the same structure, the sealing is not the same, so after the spray waterproofing agent in the product inside the formation of coatings tend to be incomplete.

Advantages

Multiple units can be operated at the same time, speeding up efficiency.

Disadvantages

Need to buy a certain number of equipment, and equipment is also a mixture of good and bad, largely subject to the performance of the equipment, the spray on the inside of the product coverage is not complete, the yield is not good to ensure.

waterproofing spray

Parylene CVD process waterproof coating

Parylene CVD process produces many performance advantages that distinguish poly paraxylene and wet coating. Compared to liquid methods, Parylene has significant application advantages over dipping, spraying, and other methods of application, where surface tension and gravity affect wet coating methods, limiting the ability to uniformly cover all part surfaces.CVD produces a homogeneous, pinhole-free, airtight, and uniformly gaseous poly paraxylene covering all surfaces including the smallest of nooks and crannies, sharp edges, or surface corrugations.

Advantages

Coating technology is simple and easy to apply at a low cost.

Can be applied to all types of PCBs, including complex multilayer PCBs.

Coating can provide good waterproof performance, effectively preventing moisture from entering the interior of PCBs

Disadvantages

Weak wear resistance, after all, the coating is in the shell part of the product, the shell is a variety of items in close contact with the part, the face of too much complexity of the use of the environment, the damage rate will be greatly accelerated, and the product in the process of using the appearance of deformation of the risk, once the deformation is unable to ensure that the water on the internal circuit board.

PCBA immersion nano waterproofing agent

This technology is currently more trendy practices, but the quality of the nano-liquid used must be over the top, and can meet the international market requirements for product quality, this technology is simple to operate, no need to increase the investment in equipment. Just need to soak the PCBA in the nano waterproof liquid for a few seconds, after the coating does not affect the electrical conductivity of the connector, can prevent corrosion of acid, alkali and salt, but it will also lead to deformation damage to the product appearance, but will not form a significant impact on the PCB, this waterproof coating can not be achieved at present more than 7 waterproof grade. Advantages

Simple operation, no need to increase the investment in equipment, no vacuum environment, coating uniformity, only need to soak the PCBA in nano waterproof liquid for a few seconds, after doing the coating does not affect the electrical conductivity of the connector, can be protected against corrosion of acids, alkalis and salts, because directly coated in the PCB board, the deformation of the appearance of the product damage will not form a significant impact on the PCB, because it is based on the PCBA immersion coating, it is almost Applicable to all electronic products.

Disadvantages

Currently can not rely on PCB nano-coating to do more than 7 waterproof, only for life waterproof.

Whether you're using waterproofing spray for electronics or other coating methods, ensuring proper protection for your PCB enhances durability, reliability, and ease of maintenance. By combining the right technique with the highest-quality materials, you can significantly improve your devices' performance in wet environments.