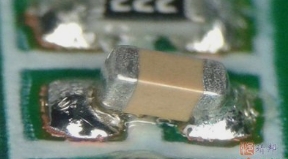

Cold spots are a common but critical quality issue during PCBA assembly. Cold spots typically refer to solder joint defects caused by insufficient temperature during the soldering process, potentially impacting the reliability and performance of the circuit board.

cold spots

1. Definition of a Cold Spot

A cold spot is a solder joint defect caused by incomplete solder melting or insufficient wetting with the substrate/component during the soldering process. Cold spots may appear as uneven, grainy, or cracked solder joints, and may even lead to electrical failure. Cold spots are particularly common in PCBA assembly, especially during reflow and wave soldering processes.

2. Causes of Cold Spots

Cold spots can be caused by multiple factors, including the following:

-nsufficient Soldering Temperature

During reflow or wave soldering, the soldering area does not reach a sufficient temperature, resulting in incomplete melting of the solder. Possible causes include improper reflow oven temperature profile settings, insufficient preheating, or uneven heat distribution.

-Thermal Capacity Differences

Differences in thermal capacity between different areas of the PCB can lead to cold spots. For example, large ground planes or components with high heat capacity can absorb more heat, causing localized areas to run cooler than expected.

-Solder Quality or Composition Issues

Using low-quality solder or inappropriate flux can lead to poor wetting and increase the risk of cold spots. Furthermore, impurities or oxides in the solder can impede proper solder flow.

-Component or Substrate Surface Contamination

Oil, oxide layers, or residue on the PCB or component surface can reduce solder wetting, leading to cold spots.

-Improper Process Parameters

Process parameter issues such as short soldering time, excessive conveyor speed, or uneven flux application can all lead to cold spot defects.

3. Impacts of Cold Spot Problems

Cold spots not only affect the appearance of solder joints but can also have serious consequences for the performance and reliability of PCBAs:

- Degraded Electrical Performance: Cold spots can cause increased resistance or intermittent connections, impacting proper circuit operation.

- Inadequate Mechanical Strength: Cold solder joints have poor mechanical strength and are prone to cracking due to vibration or thermal cycling. Long-term reliability issues: Cold spots can gradually worsen over time, leading to PCB failure, especially in high-reliability applications such as aerospace or medical devices.

4. Solutions to Cold Spot Issues

Cold spot issues can be addressed through three key approaches: design, process, and testing:

-Optimizing the Soldering Temperature Profile

Adjust the temperature profile of the reflow oven or wave soldering equipment to ensure that the soldering area reaches appropriate preheating, melting, and cooling temperatures. Thermocouple testing can be used to verify the uniformity of the temperature distribution.

-Improving PCB Design

During the PCB design phase, minimize the presence of large ground planes or concentrated layouts of high-heat-capacity components to optimize heat distribution. Additionally, properly designing pad size and spacing can help improve soldering quality.

-Selecting High-Quality Materials

Use solder and flux that meet industry standards to ensure stable composition and excellent wetting properties. Regularly inspect and clean the PCB and component surfaces to prevent contamination that may affect soldering performance.

-Optimizing Process Parameters

Adjust soldering time, conveyor speed, and flux application amount to ensure that process parameters match specific product requirements. For complex PCBAs, localized preheating or auxiliary heating techniques can be employed.

pcba

5. Strengthen Quality Inspection

Use X-ray inspection, automated optical inspection (AOI), or manual visual inspection to promptly identify cold spots. Perform cross-section analysis of critical solder joints to verify soldering quality.

V. Additional Recommendations for Preventing Cold Spots

- Operator Training: Enhance operators' understanding of the soldering process to ensure they can identify and address cold spots.

- Regular Equipment Maintenance: Regularly calibrate and maintain soldering equipment to prevent temperature control failure due to equipment aging.

- Environmental Control: Maintain stable temperature and humidity in the production workshop to reduce the impact of environmental factors on soldering quality.

Cold spots are a quality defect requiring significant attention in PCB/PCBA manufacturing. Their causes are complex, involving multiple factors, including materials, processes, and design. By optimizing temperature profiles, improving designs, selecting high-quality materials, and strengthening inspections, cold spot issues can be effectively reduced and product reliability improved. In actual production, a comprehensive approach to process control and quality management can minimize the occurrence of cold spots defects and ensure the high performance and long life of PCBAs.