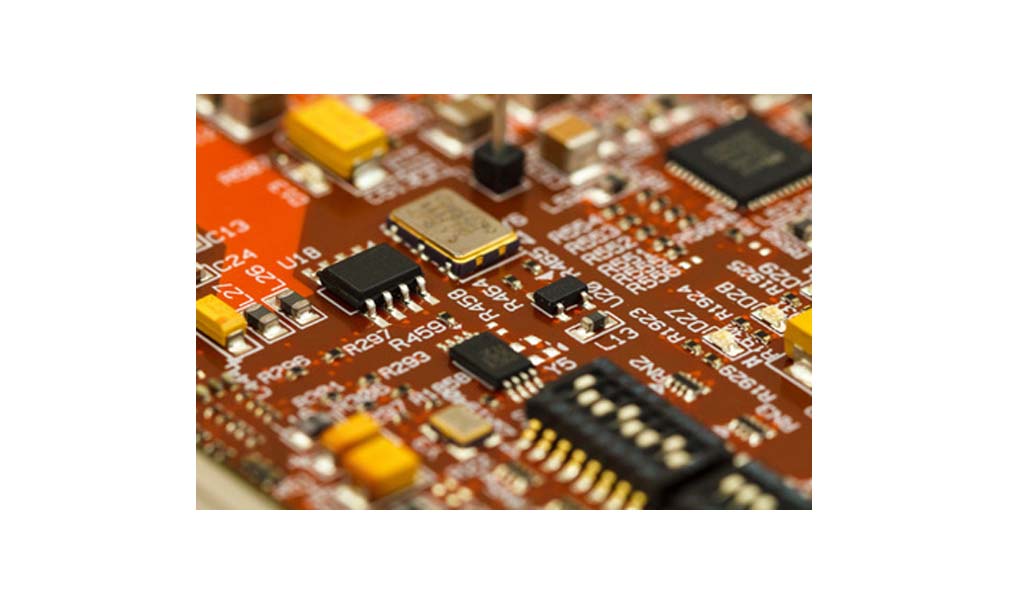

SMD: It is the abbreviation of surface mount devices, which is a type of SMT (Surface Mount Technology) PCB. In the early stage of electronic circuit board production, through-hole assembly is completely done manually. After the simple introduction of automation, they can place some pin components, and complex components still need to be placed manually before reflow soldering. Surface mounted device components are directly soldered on the surface of the circuit board, and do not need to be inserted into the hole through pins.

The following are some common surface mount devices:

SMD capacitors are mainly used for filtering, coupling, decoupling and other functions in the circuit. According to the dielectric material and packaging type, SMD capacitors can be divided into: Ceramic SMD capacitors: have small size, high reliability and good temperature characteristics, suitable for various occasions. Tantalum SMD capacitors: have high capacity, high stability and low leakage current, mainly used in high performance occasions. Organic solid SMD capacitors: have high capacity and low withstand voltage value, suitable for low voltage occasions.

SMD inductors are mainly used for filtering, voltage stabilization and other functions in the circuit. According to the structure and performance, SMD inductors can be divided into: Multilayer ceramic SMD inductors: with small size, high reliability and good temperature characteristics, suitable for various occasions. Coil type SMD inductors: with high inductance value and low DC resistance, mainly used in high current occasions.

SMD resistors are the most common components in surface mount devices. Their main function is to provide resistance in the circuit to control the current. According to the packaging method, SMD resistors can be divided into: Thin film SMD resistors: with good temperature characteristics and stability, mainly used in high-precision circuits. Thick film SMD resistors: low price, suitable for mass production and circuits with general performance requirements.

SMD diodes and transistors are semiconductor components, mainly used for rectification, amplification, switching and other functions. According to the package type, SMD diodes and transistors can be divided into: SOD package: small package, suitable for low power occasions. SOT package: larger package, suitable for medium and high power occasions.

Availability of surface mount device components (surface mount electronic components):

Although there are only a few types of conventional DIP packages that can meet all packaging requirements, the world of surface mount packaging is much more complicated. There are many types of packages, packages and lead configurations available. In addition, the requirements for surface mount components are higher. SMDs or SMCs must withstand higher soldering temperatures, and SMDs or SMCs must be selected, placed and soldered more carefully to obtain acceptable manufacturing yields. There are many components available for certain electrical needs, leading to serious problems with component proliferation. There are good standards for some components, while for others, standards are not adequate or do not exist.

Passive SMD components:

The world of passive surface mount is a little simpler. Monolithic ceramic capacitors, tantalum capacitors and thick film resistors form the core group of passive SMDs. The shapes are usually rectangular and cylindrical. The quality of the components is about 10 times lower than that of through-hole components. The surface mount resistors and capacitors are available in various case sizes to meet the various application needs in the electronics industry. Although there is a trend towards smaller case sizes, larger case sizes can also be used if the capacitance needs are large. These devices/components are available in rectangular and tubular (MELF: Metal Electrode Lead Free Face) shapes.

In the development of the electronics industry, the continuous innovation and advancement of surface mount devices have driven the performance improvement and diversification of electronic products. Its application areas cover multiple industries such as consumer electronics, communications, and medical treatment, providing strong support for the design and manufacture of various devices. Overall, the miniaturization, lightweight, and high-performance characteristics of surface mount devices will continue to lead the development trend of electronic technology and lay a solid foundation for future innovation.