X-Ray quality control and inspection offers many benefits to PCBA manufacturers. The high accuracy of the results and the ability to see hidden features are perhaps the most important advantages. Nonetheless, there are many other benefits that ensure the best quality PCBA is produced.

iPCB explores the specific benefits associated with PCBA and the X-ray method used to inspect PCBA defects.

1. Ability to inspect blind or buried vias

Via holes are a very important part of PCBA as they can easily connect different layers of the board.

However, different vias are used to connect the boards, including blind vias and buried vias.

Since these vias are not easily seen through visual inspection, it creates problems for inspectors to evaluate the integrity of these vias during quality inspection.

But the good news is that PCBA X-Ray machines can emit radiation that penetrates hidden and hard-to-reach points, making it easy for inspectors to evaluate the quality of board connections and components.

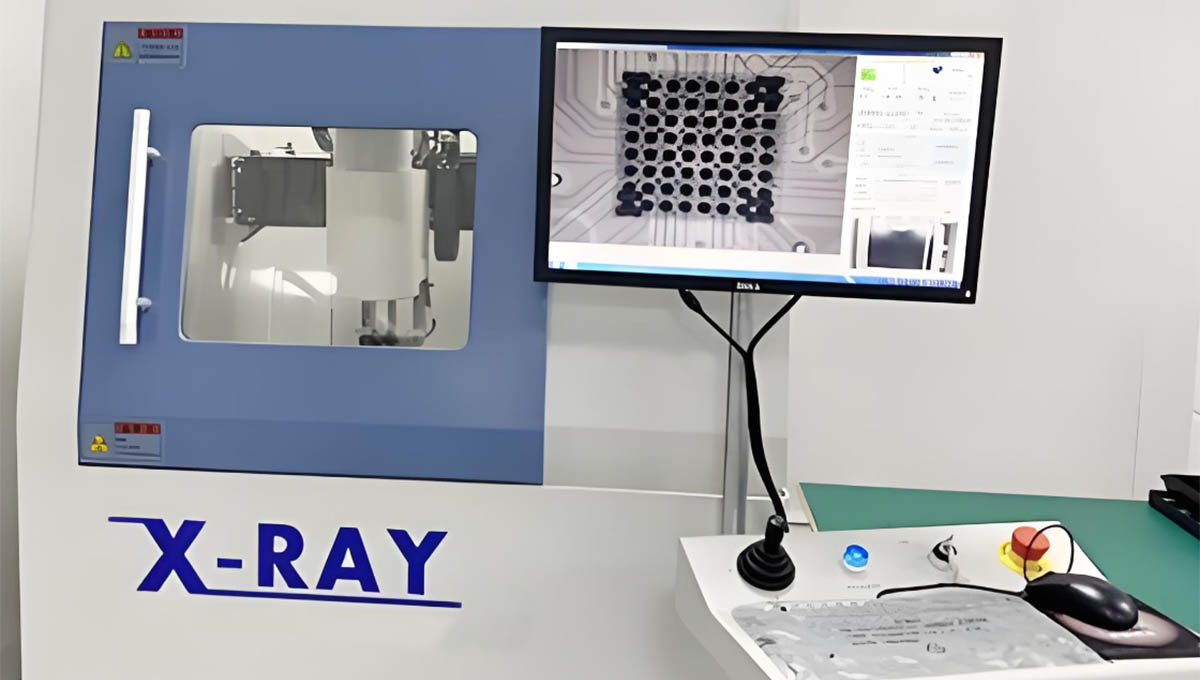

X-Ray

2. Helps check for errors in soldering methods

Often, errors occur when assembling components on a PCBA (PCBA assembly), and one of these errors is the soldering method of a specific component on the board.

If the component to be assembled on the circuit board is not part of the components included in the commonly used SMD component library, it will bring challenges to incorrectly obtain the soldering pattern.

Design engineers usually need to generate a schematic of the newly introduced component and the soldering pattern on the board.

When this schematic is missing, the soldering pattern may be wrong, which is difficult to notice using visual inspection.

However, it becomes very easy to evaluate the incorrect soldering pattern of the components already installed on the board using a PCBA X-ray machine.

3. Ability to see through BGA

One benefit of ball grid arrays (BGAs) for component arrangement is that devices can become smaller and tiny components can be installed on PCBAs.

However, BGAs still have their disadvantages, especially in terms of quality assessment and inspection. Using a ball grid array (BGA) system, components are usually tightly packed on the board with little space between the mounted components.

This tight arrangement makes it impossible for inspectors to visually identify any defects within the circuit board and the mounted components.

PCBA X-Ray machines are usually the best way to evaluate component quality and board connections by penetrating BGA components with their X-rays.

This non-destructive test (NDT) enables inspectors to see individual components from the images generated by the PCBA X-Ray machine and identify any defects.

4. Identify incorrect placement of decoupling capacitors

Decoupling capacitors are usually an important part of every electronic device because they not only ensure the stability of the power supply, but also eliminate oscillations and transients.

These capacitors are always connected in parallel with respect to the power supply. In addition, they should be as close as possible to the components that are in contact with the power supply.

However, incorrect placement of these capacitors often leads to suboptimal device performance and may even cause harm to the user if they explode.

Due to the tight mounting of electronic components on the PCBA, it may be difficult to find incorrect connections through visual inspection alone.

The PCBA X-Ray machine enables inspectors to easily identify any incorrect placement and correct this error before releasing the product.

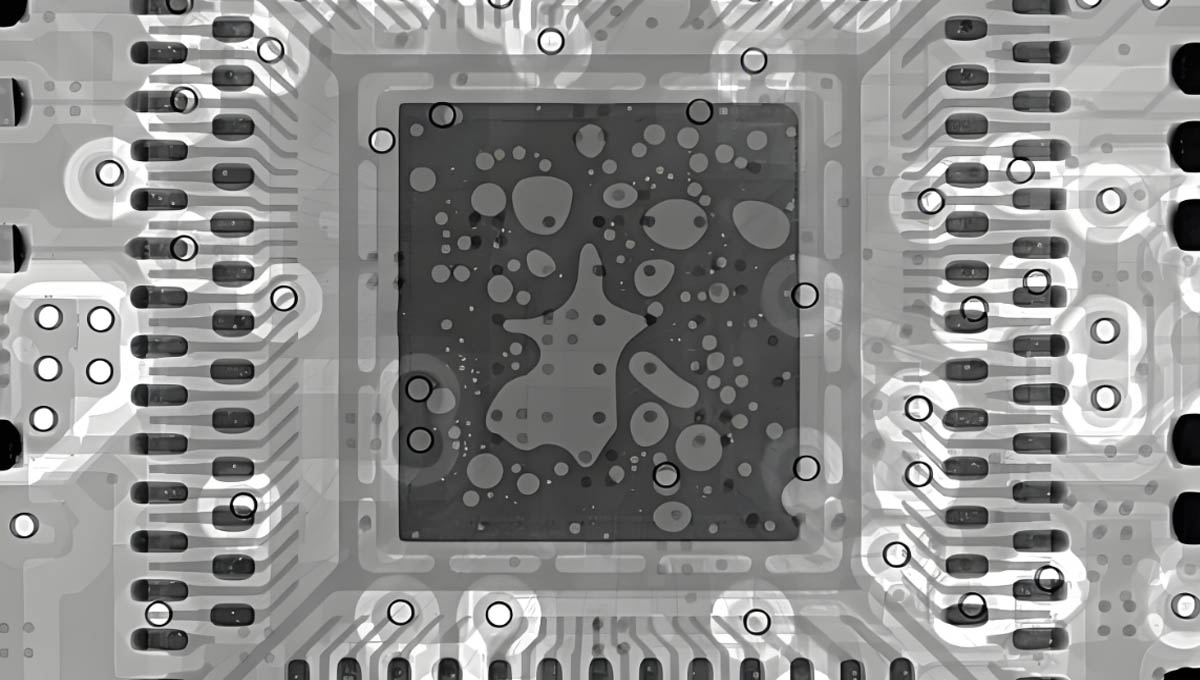

5. Allow inspectors to view solder voids

Soldering is the connection between the PCBA and the component. If there is an error in soldering, the connection will fail and pose a challenge to product quality.

In addition, the product may not work optimally and may even cause harm to the user.

To avoid these challenges, inspectors check for solder voids that can cause low-quality connections during inspection.

However, since BGAs are tightly packed during the installation process, it is difficult to satisfactorily inspect soldering with visual inspection.

PCBA X-Ray machines are often the preferred solution to this challenge because it enables inspectors to accurately detect solder voids that can cause poor connection or product quality.

X-Ray

6. Easy to Identify Pinhole Filling

One method of connecting components on PCBAs is through-hole connection, especially for components that require stronger connections in layers.

However, this connection often suffers from certain defects, including pinhole filling. This problem is usually caused by gas leaking out during soldering.

This gas is usually water vapor, which often causes pinhole filling if the heat of soldering is too great, causing the gas to continuously escape.

Using inspection methods such as visual inspection and other inappropriate methods, it is often difficult to identify these anomalies.

However, PCBA X-Ray machines provide the best and accurate way to identify pinhole filling during quality assessment to ensure the integrity of soldering operations.

X-ray machines provide various benefits for quality control of PCBAs during the manufacturing process. Another thing you should consider is the cost of failure, as this can be very costly if the quality of your product is sub-par. Quality control with a PCBA X-ray machine can help save unnecessary costs from failures and recalls after your product leaves the factory.