15 years of high frequency circuit board manufacturing experience has made iPCB a leading manufacturer of this technology. Polytetrafluoroethylene (PTFE) multi-layer circuits, Rogers PCB materials, and the use of hybrid materials (FR4 and PTFE) to design and manufacture high-frequency circuit boards have become the standard technology for iPCB.

iPCB has long worked closely with our material suppliers (Rogers, Taconic, neltec, etc.). ipcb's engineering team is staffed with highly trained high frequency circuit board developers who can help you choose the appropriate high frequency circuit board structure or design.

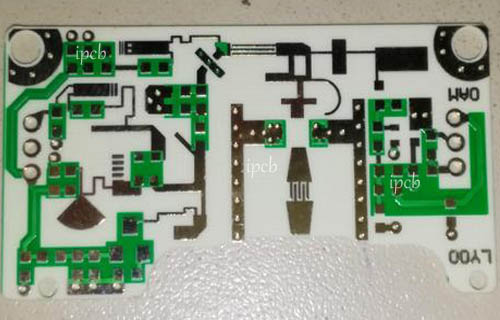

High frequency circuit board (high frequency PCB)

What is high frequency PCB?

High-frequency electronic equipment is a development trend, especially wireless networks. With the rapid development of satellite communications, information products are developing in the direction of high-speed PCB and high-frequency PCB. Therefore, the development of new products always requires the use of high-frequency PCB substrates, satellite systems, mobile phone receiving base stations, etc. These communication products must use high-frequency PCBs.

High frequency circuit board indicators.

1. DK should be small and stable enough, usually the smaller the better. High Dk may cause signal transmission delays.

2. DF should be small, which mainly affects the quality of signal transmission. A smaller DF can reduce signal loss accordingly.

3. The thermal expansion coefficient should be the same as that of the copper foil as much as possible, because the difference will cause the copper foil to separate during hot and cold changes.

4. In humid environments, water absorption must be low and high, which will affect iPCB.

5. Heat resistance, chemical resistance, impact resistance and peel resistance must be good.