As technology develops, the demand for more functions to be packed into smaller packages is also growing. PCBs designed using high-density interconnect (HDI) technology tend to be smaller because more components are packaged in a smaller space. HDI PCBs use blind, buried and microvias, through-holes in pads, and very fine traces to fit more components into a smaller area. High-densityinterconnect (HDI) printed circuit design and manufacturing began in 1980 when researchers began to study ways to reduce the size of through-holes in PCBs. The first production-grade or sequential printed circuit boards came out in 1984. Since then, designers and component manufacturers have been looking for ways to integrate more functions on a single chip and a single circuit board. Today, HDI circuit board design and manufacturing have been incorporated into IPC-2315, IPC-2226, IPC-4104 and IPC-6016 standards.

HDI PCB has many advantages that make it widely used in the modern electronics industry. It is a technology that supports miniaturization, which has become one of the basic characteristics of all electronic development. HDI technology uses automated production lines and advanced PCB production equipment to achieve a high degree of automation and informatization of the production process,effectively improving production efficiency and quality. HDI technology uses environmentally friendly materials and processes to reduce pollution to the environment, which is in line with the current development trend of green environmental protection. HDI PCB can also improve electrical performance by shortening the path for transmitting electrical signals, thereby speeding up signal transmission and reducing the risk of these signals being lost or intercepted. Therefore, a small HDI circuit board can combine multiple functions to achieve high-speed signal transmission and reliable connection. One of its most important features is smaller size and lighter weight. As the density of circuits increases, we find that they require fewer layers and materials, which helps make them lighter and thinner, making them ideal for portable and wearable devices. Compared to traditional PCBs, HDI PCBs offer superior functionality and design flexibility by adding components on two outer layers. It can also accommodate very high bonding densities while maintaining structural integrity. Therefore, this technology gives us greater freedom to design and innovate, while traditional PCBs are limited by the number of layers and directional density. Finally, by incorporating microvias and other HDI features into its configuration, it is easier to place more components in a very short distance, which helps to reduce transmission time and save energy. It also enhances on-board communication, making it more reliable and more suitable for difficult and complex applications, which makes them more efficient in the long run.

Key points of HDI PCB design: Since the design process of HDI PCB is a process that all aspects of the manufacturing stage rely on, tracking the design requirements with high accuracy can enable manufacturers to streamline the manufacturing process and avoid errors that may lead to re-manufacturing, thereby ensuring the successful implementation of the manufacturing stage. During the design process, the width and spacing of components must be considered to maintain signal integrity and ensure that there is no interference in narrow bands. To ensure reliable communication, the complexity of the connection between high-density layers containing a large number of elements must be considered to accommodate dense circuits in a limited space. It is imperative to select the appropriate materials that are compatible with the design, such as copper foil, which directly affects the quality and effectiveness of the final product. Methods for regulating and dissipating heat, especially in designs that contain a large number of components to perform their functions. It is necessary to trace the thermal path and place the components appropriately to evenly distribute the heat. Finally, it is necessary to follow up on the details of microchannel integration, which is considered one of the most important components of HDI PCB systems. They act as channels to transmit signals between different layers. They significantly reduce the interference between signals, thereby obtaining high reliability and effectiveness of the produced electronic devices.

Follow the following standards when designing HDI designs:

IPC/JPCA-2315: Guidelines for High-Density Interconnect Structures and Microvia Design.

IPC-2226: Standard Specification for Material Properties, Microvia Formation, Interconnect Structures, and Design Rule Selection.

IPC/JPCA-4104: This standard establishes the qualification and performance specifications for dielectric materials used in high-density interconnect structures.

IPC-6016: General Specification for High-Density Substrates.

A circuit board with the following specifications can be considered an HDI design.

Line spacing should be ≤100μm

Through hole diameter ≤150um

Capture pad ≤400μm

Capture pad density >20 pads/cm2

HDI material selection:

The next step is to select materials that are suitable for HDI manufacturing and meet temperature and electrical requirements. The selected material will affect the electrical performance of the trace. The dielectric loss of the material will also have an impact. Other parameters such as maximum withstand temperature, maximum frequency of the signal, and CTE are also important in the material selection process.

Some commonly used materials for HDI boards include:

Normal speed and loss: FR4 series

Medium speed, medium loss: Nelco N7000-2 HT

High speed and low loss: Isola I-Speed

Extremely high speed, extremely low loss (RF/microwave): IsolaTachyon100G

After the material is determined, plan an efficient PCB stacking and microvia structure.

Manufacturing process:

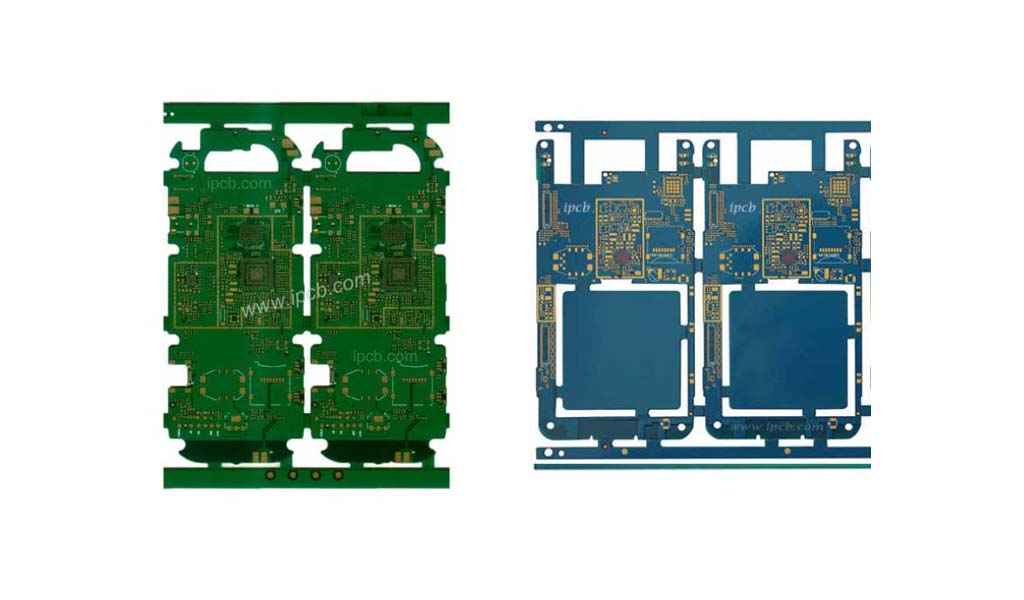

The manufacturing process of HDI boards is relatively complex, including laser holes (Laser Via), stacked copper plates, etching technology, etc. to achieve high-density interconnection and complex circuit wiring. In contrast, the manufacturing process of ordinary PCB is relatively simple, generally using photolithography, etching process, etc.

Cost:

Due to the more complex manufacturing process of HDI board and higher line density and technical requirements, its manufacturing cost is relatively high. Ordinary PCB has a lower manufacturing cost and is suitable for some application scenarios with low line density and technical requirements.

Testing:

After the HDI PCB board is completed, it needs to be strictly tested and verified. The difficulty of the test lies in how to detect the parts that are difficult to observe such as blind holes and buried holes. In addition, signal integrity testing and EMI/EMC testing are required to ensure the performance and reliability of the board. Therefore, testers need to have deep testing knowledge and experience, as well as proficiency in testing equipment and software.

Application:

Due to its unique advantages, HDI boards are widely used in various electronic devices. The main application areas include but are not limited to:

Mobile communication products: such as mobile devices such as smartphones and tablets, use HDI boards due to their small size and high performance requirements.

Consumer electronics: including consumer electronics such as TVs, speakers, cameras, etc., HDI boards can meet their small size, high performance and appearance requirements.

Medical equipment: In medical devices, the high-density design of HDI boards can meet the needs of more functional integration.

Industrial control equipment: Such as automation equipment, robots, etc., HDI boards can provide higher signal transmission rate and stability.

Future development trend of HDI industry:

Industry demand forces HDI to develop rapidly. Electronic products such as smartphones, tablets and wearable devices are developing in the direction of miniaturization, multi-function and long battery life. Taking Apple as an example, iPhone4S first introduced Anylayer HDI, and iPhoneX first introduced SLP. The stacked SLP technology makes the motherboard size of iPhoneX only 70% of the iPhone8Plus motherboard; after the communication technology is upgraded to 5G, Huawei, OPPO, and vivo's 5G models use Anylayer HDI motherboards in large quantities, and the HDI order of ordinary mid- and low-end model motherboards has also increased. Smartphone motherboards have experienced the process of evolution from first-order HDI to high-order, any-order HDI, and then to SLP. The line width/line spacing continues to decrease, and the component density continues to increase.

Automotive HHIDI product space is broad. With the development trend of intelligence, from the in-car entertainment system to ADAS assisted driving and automatic driving systems, the configuration performance of the body domain controller has been improved, and the number of high-speed computing chips carried in a limited volume has increased. HDI has a large growth space. For example, Tesla's ADAS controller uses 3-order 8-layer HDI. In the future, in-car motherboards are expected to repeat a path similar to that of mobile phone motherboards, upgrading from low-end to high-end hdi board processes.