PCBA manufacturing in the SMT many people sound relatively unfamiliar, do not know what the props do, do not know what positions? Who is suitable to do it?

PCBA manufacturing plant SMT workshop is divided into DIP line and SMT line.

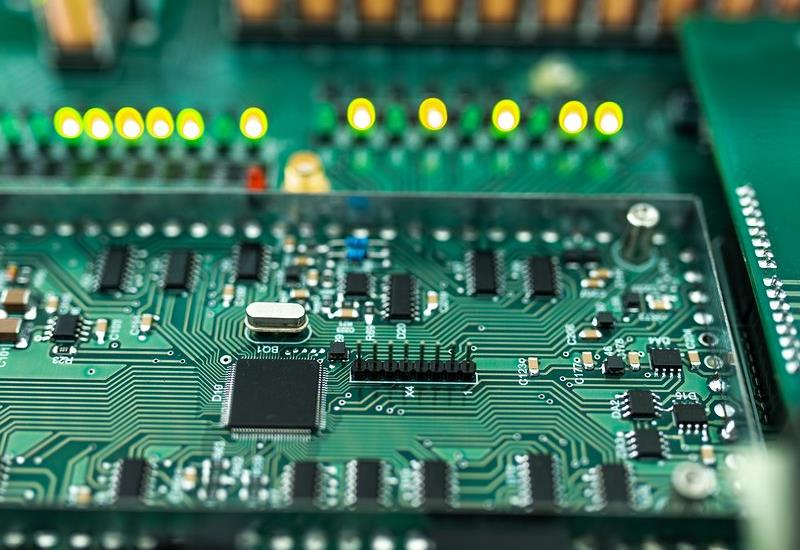

SMT refers to the surface mount technology, that is, the electronic components through the equipment to the PCB board above, and then through the furnace heating to fix the components to the PCB board, resulting in PCBA is PCB Assembly.

DIP is a hand-inserted component, such as some large connectors, equipment can not be prepared to hit the PCB board, through people or other automated equipment inserted into the PCB board.

The SMT line mainly consists of solder paste printers, loaders, pre-furnace visual inspection, post-furnace visual inspection, packaging, etc. The DIP line mainly consists of board feeders and feeders, and the DIP line consists of board feeders and feeders.

DIP line mainly has board feeder, board remover, inserter, furnace worker, after furnace solder joints visual inspection, etc.

Each process of SMT is a post: operator, pre-furnace visual inspection, post-furnace visual inspection, maintenance, management, team leader, head, regulator programmer.

Printing: the use of printing machines to brush solder paste on the PCB, the specific content of the work depends on the use of fully automatic printing machine or semi-automatic printing machine, as well as the degree of automation put aside in the production line

Operator: The operation of the SMD machine, mainly responsible for feeding and general alarm handling.

Pre-furnace: Some places also called in the inspection, responsible for checking the PCB out of the paste machine has no parts paste leakage or paste crooked and other bad phenomena (some products are simple or high degree of automation of the production line of the factory does not have this workstation)

After the furnace: check the reflow soldering out of the product whether there are bad and paste labels, etc.

PCBA appearance maintenance: this can not be counted on the production line, generally separate, responsible for repairing the appearance of bad products after the furnace check out!

PCBA manufacturing AOI inspection: AOI test board (this is not the same for each equipment, and not necessarily every family has)

PCBA manufacturing SMT workshop work is harmful to the human body?

SMT workshop needs to be ventilated, and employees need to wear overalls and protective gloves during the work because they will come into contact with some chemicals during the work.With proper protection, it is not harmful to human health, but if you have allergies, you need to report in advance to prevent accidents.

Is SMT work good?

SMT operators are basically on their feet and can move around during work because they need to pick up data items. Position labour intensity in general, need to understand some of the professional knowledge of machine operation, if then through their own efforts to take the initiative to learn the maintenance of equipment, then in the future job search also have a skill, can be considered a technical position.