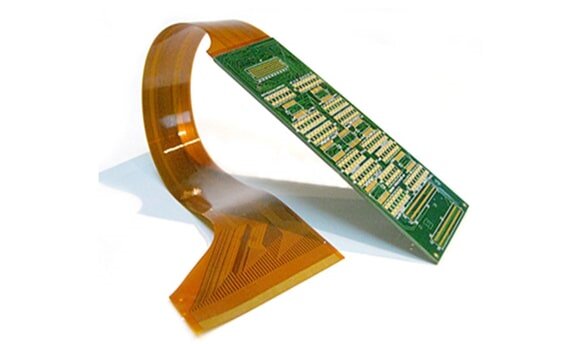

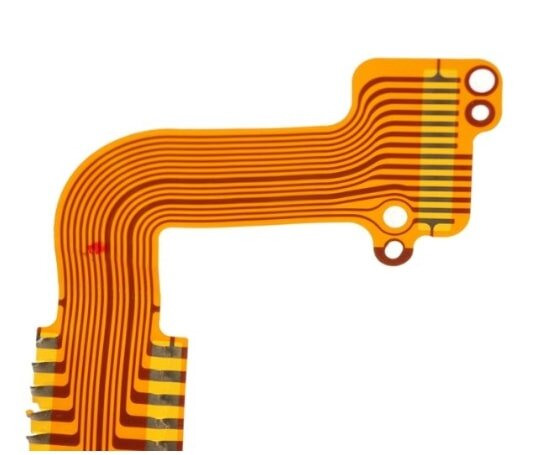

Flexible panel boards, also known as soft circuit boards, are favored for their light weight, thin thickness, and free bending and folding.

The type of flexible panel board material determines its physical and electrical properties. Therefore, it must be carefully selected, usually based on the intended use of the circuit board. In view of this, common flexible PCB materials include materials for making substrates and cover layers, or if necessary, adhesives and stiffeners.

Manufacturers use a variety of materials to make flexible panel boards, the most common of which are polyimide (PI) and polyester (PET). Polyimide is the most popular flexible PCB material for the substrate layer, providing excellent flexibility for dynamic and non-dynamic applications. Polyimide flexible PCB materials are also heat resistant. In terms of electrical properties, polyimide flexible circuits have good dielectric strength, among other benefits. Polyester is another popular flexible PCB substrate. Compared with polyimide, it is an economical choice for simple flexible circuits. Polyester is also cheaper than polyimide, making it an attractive choice for cost-sensitive projects.

Advantages of flexible panel board (FPC):

Flexible printed circuit board is a printed circuit made of flexible insulating substrate, which has many advantages that rigid printed circuit board does not have:

(1) It can be bent, rolled, folded freely, can be arranged arbitrarily according to the spatial layout requirements, and can be moved and stretched arbitrarily in three-dimensional space, so as to achieve the integration of component assembly and wire connection;

(2) The use of FPC can greatly reduce the size and weight of electronic products, which is suitable for the development of electronic products towards high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products;

(3) FPC also has good heat dissipation and solderability, as well as easy installation and low overall cost. The combination of soft and hard design also makes up for the slight lack of flexible substrate in component carrying capacity to a certain extent.

Disadvantages of flexible panel board (FPC):

(1) High cost: Since flexible PCB is designed and manufactured for special applications, the initial circuit design, wiring and photographic plate costs are relatively high. Unless there is a special need to apply flexible PCB, it is usually best not to use it when it is applied in small quantities;

(2) It is difficult to change and repair flexible PCB: Once the flexible PCB is made, it must be changed from the base map or the compiled photolithography program, so it is not easy to change. Its surface is covered with a protective film, which must be removed before repair and restored after repair, which is a relatively difficult task;

(3) The size is limited: When flexible PCB is not yet popular, it is usually manufactured using an intermittent process. Therefore, it is limited by the size of the production equipment and cannot be made very long or wide;

(4) It is easy to be damaged due to improper operation: improper operation by the assembly personnel can easily cause damage to the flexible circuit, and its soldering and rework require trained personnel to operate.

Application of flexible panel board

As you have now learned, flexible circuit boards help provide dynamic flexibility, allowing devices to operate according to the manufacturer's requirements. This is very useful in modern devices such as health trackers, medical devices, fitness wearable devices, smart watches, cameras, mobile phones, tablets and laptops. The durability, reliability and excellent performance of flexible printed circuit boards make them the first choice for manufacturing certain parts of machines such as driverless cars and aircraft.

Industries that require flexible panel boards include but are not limited to:

- Consumer electronics

- Wearable devices

- Automotive industry (e.g. airbag systems)

- Computers and laptops

- Medical devices (e.g. ultrasonic probes)

- Telecommunications

- Aerospace industry

- Satellites

With the explosive growth of wearable devices, flexible displays and smart devices, the demand for flexible circuit boards has increased significantly. The industry is being used more and more widely, and the local flexible circuit board industry is gradually entering a period of explosive growth. In the context of electronic products pursuing light, thin, short and small designs, ultra-thin and stretchable flexible panel boards contain huge opportunities to promote the further development of related equipment.