What is a Gerber file?

Gerber is a file format. The standard gerber file format can be divided into RS-274 and RS-274X, Gerber X2. RS-274 gerber file format and aperture are separate files. RS-274X format aperture is integrated in the gerber file.

The Gerber file is an industry standard in the PCB industry. No matter how powerful your design software is, you must eventually create a Gerber file in order to create a photorealistic film. Gerber files are the output of the circuit design process and contain all the details used by the PCB manufacturer, Gerber files are used in the PCB manufacturing and assembly process.

The file flow of PCB circuit boards:Schematic->NETLIST->Automatic Layout->Automatic Layout->PCB-Gerber data, drilling data, milling data,and other data.

Gerber format is a collection of file formats used by PCB industry software to illustrate images of PCBs (circuit layers, soldermask layers, character layers, etc.) and drilling and milling data.Gerber is available in three formats: Gerber X2, the newest Gerber format, and RS-274X (Extended Gerber Format) and the older RS-274-D. The Gerber format was originally developed by Gerber, Inc. and is now part of Ucamco.The Gerber format is the standard format for image conversion in the circuit board industry.

Gerber files

Format classification of Gerber files

1.Gerber X2 (latest format)

Gerber X2 is an upgraded version of RS-274X and is the latest Gerber format,which not only embeds board stacking information,but also inserts CAD content,reinforcing the existing image data format and new features that can greatly improve the overall design, engineering and production efficiency.

2.RS-274-X (Common)

RS-274X (also known as Extended Gerber Format,or X-Gerber Format) is a 2D vector image description format and the standard format for image description in the circuit board industry.RS-274X is a readable ASCII format containing a set of control codes and coordinate information.The elements that make up the image are lines and flashes with shapes drawn at specific locations.Positive and negative graphic objects can be combined.

The RS-274X file contains a complete description of the image of each layer of the board, with all the elements needed to create an image of the board, without the need to extend the file.Aperture can define positive and negative objects. Copper skins do not need to be specified as ‘Fill Blocks’ or ‘Fill Lines’ as in RS-274-D.

The RS-274X is complete for all layers of the board. Powerful. The RS-274X is a complete,robust and clear standard description of the board's layers that can be imported and processed automatically.This enables it to be used for fast and secure data conversion and trusted and automated workflows.

3.RS-274-D (commonly used, phased out by Ucamco in 2015)

The old RS-274-D (also known as the standard Gerber format) is a data format derived from EIA's RS-274-D standard code for controlling multi-domain CNC machines. Gerber RS-274-D is used to control vector light plotters, which are two-dimensional CNC machines.Gerber RS-274-D is an ASCII format containing control codes and X and Y coordinates.

The Gerber RS-274-D was developed in the 1960‘s and 1970’s to control vector light painters.The RS-274-D does not contain coordinate organisation or ASCII information.It does not contain coordinate organisation or Aperture information. Aperture is a description of the shape of an object,similar to the fonts in a PDF file.The light-painter operator sets the coordinate organisation and Aperture manually and describes it in a text file, called an Aperture file or, for historical reasons, a wheel file. Aperture files are mainly read and written by the operator and there is no standard.Every EDA software and even every designer has their own different aperture file design and name conversion habits. The PCB manufacturer must understand and manually input the aperture file into the CAM system.

RS-274-D only supports simple image operation. Because of its extreme limitations, one had to create complex shapes such as stroking, i.e., fill blocks or fill lines. the RS-274-D was able to conveniently control the vectorial light plotter, but was extremely limited by the capabilities of the process at the time. It was suitable for manual processes, not for reliable and automated data conversion for PCB design and manufacturing.RS-274-D is a numerical standard, not an image description standard. An RS-274-D file is useless without an Aperture file to match it. However, there is no unified standard for Aperture files. In addition, RS-274-D is obsolete.

4. Other Gerber formats: RS-274.Fire 9000.Mda 9000.Barco DPF.

Gerber data format: integer bits + decimal digits, commonly used: 3:3 (metric, integer 3 bits, decimal 3 bits)

2:4 (English, integer 2 bits, decimal 4 bits)

2:3 (English, integer 2 bits, decimal 3 bits)

3:3 (English, whole 3 bits, decimal 3 bits)

Gerber Units: METRIC (mm), ENGLISH (inch or mil)

Gerber unit conversion: 1 inch = 1000 mil = 2.54 cm = 25.4 mm, 1 mm = 0.03937 inch = 39.37 mil

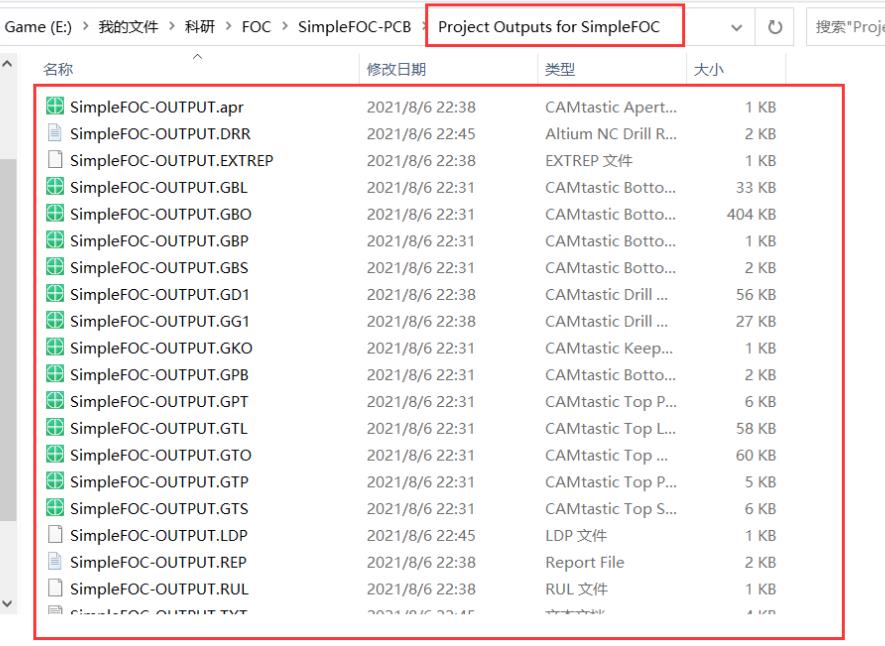

Gerber file

What is the function of Gerber file?

CAD file generally refers to the original PCB design file, such as protel, PADS and other PCB design files, while the user or enterprise design department,often out of various considerations is only willing to provide the Gerber file of the circuit board to the production department.

Gerber files are all circuit design software can produce files,in the electronic assembly industry is also known as stencil data (stencil data), in the PCB manufacturing industry is also known as optical drawing files.It can be said that Gerber file is the most common and widespread file format in the electronic assembly industry.For an electronic production enterprise,it is very important to have a computer-assisted manufacturing CAM software that can handle Gerber files, which can help to improve the quality of the preparation, manufacturing and testing processes for the arrangement of product production.

Gerber file is the standard format of EIA, which is divided into RS274-D and RS274-X,of which RS274-X is the extension file of RS274-D.Manufacturing departments should request the user or design department to provide RS274-X Gerber files as much as possible when the conditions permit, so as to facilitate the production preparation of each process.

Gerber data is generated by Photoplotters.Photoplotters consist of a sophisticated servo system that controls an X-Y table to which a high contrast film is attached.A light source shines on the film through a shutter. The shutter contains an aperture*** and focuses on the film.The controller translates the Gerber commands into appropriate table movement,aperture*** rotation and shutter opening and closing.The result is what we commonly see as a Gerber file.

The Gerber file is a file that can be generated by all circuit design software,and is also known as a stencil file (stencil data) in the electronic assembly industry,and an optical drawing file in the PCB manufacturing industry.It can be said that Gerber file is the most common and widespread file format in the electronic assembly industry. For an electronic production enterprise,it is very important to have a computer-assisted manufacturing CAM software that can handle Gerber files, which can help to improve the quality of the preparation, manufacturing and testing processes for the arrangement of product production.

Gerber file is the standard format of EIA, which is divided into RS274-D and RS274-X, of which RS274-X is the extension file of RS274-D.The production department should request the user or the design department to provide RS274-X Gerber files as far as possible when the conditions permit, so as to facilitate the production preparation of each process.

CAD files generally refer to the original PCB design files, such as protel, PADS and other PCB design files,while the user or enterprise design department is often willing to provide only the Gerber file of the circuit board to the production department due to various considerations.