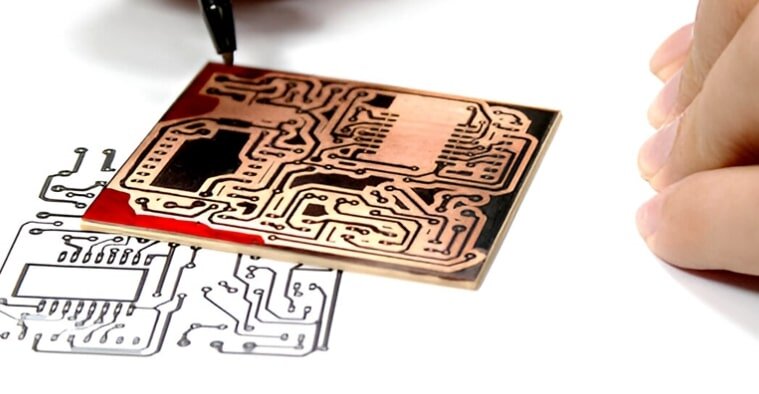

PCB board etching kit In the context of the rapid development of modern electronic technology, printed circuit boards (PCBs) have become the core foundation of various electronic products. From simple toys and home appliances to complex industrial automation equipment and communication systems, almost everything relies on PCBs. Among the many processes in PCB manufacturing, etching is one of the most crucial steps. To facilitate the production of small batches of PCBs for individual makers, laboratories, educational institutions, or small businesses, PCB board etching kits have emerged and are widely used.

Before understanding PCB board etching kits, let's first understand what PCB board etching is. When people mention PCBs, many think of the densely packed circuit boards in electronic products, but few know how those precise circuit lines are "carved." In fact, the core technology behind this is the PCB etching process. In PCB etching, at a certain temperature, etching solution is evenly sprayed onto the surface of copper foil through a nozzle. This reacts with the copper, which is not protected by etching resist, in a redox reaction, removing unwanted copper and exposing the substrate. After a stripping process, the circuitry is formed.

What is a pcb board etching kit?

A PCB board etching kit is a tool kit designed for handcrafting or small-batch production of PCBs. Its main function is to chemically etch away unwanted copper layers on the circuit board, creating the desired conductor patterns. Compared to traditional mass production methods, etching kits require no expensive equipment, are simple to operate, and offer high safety, making them suitable for individual users and educational purposes.

Main Components of a PCB Etching Kit

A complete PCB etching kit typically includes the following components:

1. Etching Solution

The etching solution is the core material of the kit. Common etching solutions include:

Ferric Chloride (FeCl₃)

Ammonium Persulfate

Mixed acids (often used in industrial production)

Ferric chloride is widely used due to its stable operation, low cost, and good results.

pcb board etching kit

2. Etching Tank or Container

Mostly plastic tanks, used to hold the etching solution, providing corrosion resistance. Some kits also include heating devices to improve etching efficiency.

3. Protective Equipment

Including gloves, masks, and safety glasses to ensure safe operation and avoid skin contact with the etching solution.

4. Transfer Materials or Photosensitive Boards

Depending on the process, this may include:

Thermal transfer paper

Photosensitive film

Photosensitive board. Its function is to transfer circuit patterns onto the copper surface of the PCB.

5. Cleaning and Auxiliary Tools

Such as sponges, wiping cloths, degreasers, and brushes, used to clean the circuit board and improve etching results.

Why use a pcb board etching kit?

PCB etching kits are used for the fabrication and repair of printed circuit boards (PCBs). They precisely remove excess copper, leaving only conductive circuit paths, a core step in enabling electronic devices to function. PCB etching kits are very useful for prototyping, small-batch production, learning, and hobby projects because they allow users to independently control the manufacturing process, enabling low-cost customized production and testing of new designs.

Main uses

Prototyping: Allows electronic engineers to quickly test new ideas and designs without relying on third-party manufacturing.

Small-Batch Production: Suitable for situations requiring small batches or customized PCBs.

Learning and Hobby: A practical tool for electronics enthusiasts and beginners to explore electronic products and improve their skills.

Repair and Modification: Can be used to repair or modify existing PCBs.

Why use an pcb board etching kit instead of other methods?

Precise Control: Etching is a critical step that affects the performance and reliability of the circuit board. Using a kit provides precise control over the process.

Economic Benefits: For small-batch production or prototyping, using a kit is more cost-effective than large-scale production.

Flexibility: Users can design and produce PCBs according to their own needs, without being limited to standard products.

Educational Value: Helps users gain a deeper understanding of the PCB manufacturing process.

pcb board etching kit

Precautions during etching:

Always remember safety first when using chemicals and heated tools. When etching PCBs, follow these practices, as emphasized in many PCB etching guidelines:

Always wear chemical-resistant nitrile or latex gloves to protect your skin.

Wear safety goggles to protect your eyes from chemical splashes and other particles.

Wear an apron or lab coat, as etching agents can permanently stain fabric.

Always etch PCBs in well-ventilated areas or open spaces.

Never work near the kitchen.

Never pour used etching solution into the sink. Follow local laws and regulations regarding the handling of such chemicals.

Wash your hands after etching and keep children and pets away from the work area.

A safe laboratory is essential for efficient operation. Following these guidelines not only protects your safety but also ensures your projects proceed smoothly and prevents accidents.

PCB pcb board etching kit are highly practical tools that make small-batch PCB production simple, economical, and efficient. For electrical engineers, students, and makers, they not only help quickly realize circuit designs but also deepen their understanding of electronic principles through practice. With the rise of open-source hardware and DIY culture, the demand and application of pcb board etching kit will become increasingly widespread.