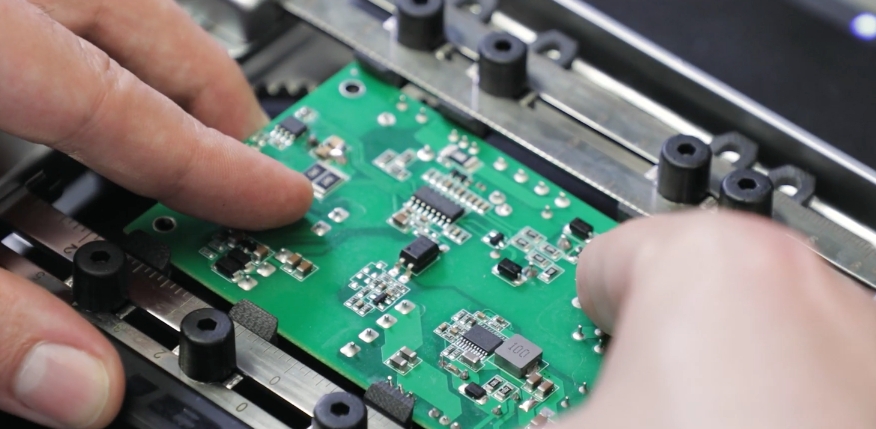

In the modern electronic manufacturing industry, substrate holders, as key components, play an irreplaceable role. They not only support and protect core components such as circuit boards and integrated circuits, but also affect the overall performance and reliability of the product.

1. Definition of substrate holder

Substrate holders, also known as circuit board holders or electronic component holders, are components specially designed to support and fix electronic substrates (such as PCB boards, FPC boards, etc.). They are usually made of metal, plastic or other high-performance materials to ensure sufficient strength and stability. The design of substrate holders varies to meet the needs of different electronic devices.

2. Types of substrate holders

There are many types of substrate holders, which can be divided into the following categories according to factors such as materials, structures, and uses:

Metal holders: Made of metals such as aluminum alloys and stainless steel, they have high strength, good thermal conductivity and electromagnetic shielding properties, and are often used in electronic devices that require high stability and heat dissipation performance.

Plastic holders: Made of plastic materials such as nylon and polycarbonate, they have the advantages of light weight, low cost, and easy processing. They are suitable for electronic products with certain requirements on weight and cost.

Composite bracket: Combining the advantages of metal and plastic, such as carbon fiber reinforced plastic, it provides higher strength and lighter weight, and is often used in high-end electronic devices.

Adjustable bracket: Designed with an adjustment mechanism, the height and angle can be adjusted as needed, which is convenient for installation and debugging and suitable for complex electronic equipment.

3. The role of substrate bracket

The substrate bracket plays multiple roles in electronic manufacturing:

Support and fixation: Provide stable support to ensure that the substrate will not shift or deform during installation and operation, and protect the circuit board and components from physical damage.

Heat dissipation: The metal bracket has good thermal conductivity, which helps to dissipate the heat generated by the electronic equipment during operation in time, and improve the stability and service life of the equipment.

Electromagnetic shielding: The metal bracket can form an electromagnetic shielding layer, reduce electromagnetic interference, and protect the circuit board and components from interference from external electromagnetic fields.

Installation and connection: Provide standardized installation interfaces and connection points to facilitate connection and assembly with other electronic components and parts, and improve production efficiency.

4. The importance of substrate holders in electronic manufacturing

As a key supporting structure in electronic manufacturing, the importance of substrate holders is self-evident:

Improve product quality: Stable support and fixation can ensure the precise alignment and connection of circuit boards and components, reduce the failure rate caused by vibration, impact and other factors, and improve the reliability and stability of products.

Optimize heat dissipation performance: Good heat dissipation performance can ensure that electronic equipment can still work normally in a high temperature environment, avoiding performance degradation and damage caused by overheating.

Reduce production costs: Standardized design and easy-to-process materials can reduce production difficulty and cost, improve production efficiency, and meet the needs of large-scale production.

Promote technological innovation: With the continuous miniaturization and complexity of electronic equipment, the requirements for substrate holders are also getting higher and higher, which has promoted the research and development and application of new materials and manufacturing processes.

Substrate holders play a vital role in electronic manufacturing. They not only support the core components of electronic equipment, but also affect the performance, reliability and cost of products. With the continuous development and innovation of electronic technology, the design and materials of substrate holders are also constantly updated and optimized to meet the needs of more complex and diverse electronic equipment. In the future, we can expect the emergence of more efficient, environmentally friendly and intelligent substrate holders solutions, injecting new vitality into the development of the electronics manufacturing industry.