1. What is a universal circuit board?

Universal PCB, also known as a universal experiment board or prototype board, is a standardized printed circuit board (PCB) that can be used to quickly build and test electronic circuits without customized design. It is widely used in electronic research and development, educational experiments and small-batch production.

Unlike custom PCBs, universal circuit boards usually use standard sizes and layouts, such as:

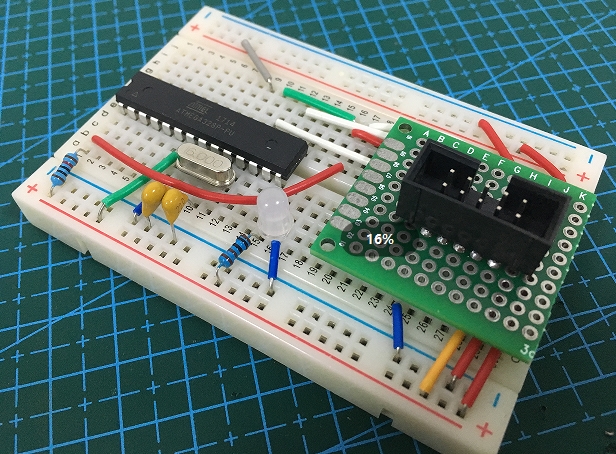

Breadboard: solderless design, suitable for rapid prototype verification.

Perfboard/Stripboard: with through-hole pads, suitable for manual soldering of fixed circuits.

Modular development boards (such as Arduino, Raspberry Pi): integrated with common interfaces, convenient for secondary development.

universal PCB

2. The core advantages of universal circuit boards

Quick verification does not need to wait for customized PCB production, and the circuit test function can be directly built.

Low cost, suitable for small-batch projects, reducing proofing costs.

Flexible modification, component layout can be adjusted or devices can be replaced at any time.

Education-friendly, widely used in electronic experiment courses to help students understand circuit principles.

3. Typical applications of universal circuit boards

Electronic prototyping

Engineers use breadboards or perforated boards to verify circuit designs such as sensors, power management, and signal processing.

For example: using ESP8266 modules to build Internet of Things (IoT) prototypes. Teaching and experimental university laboratories often use universal boards to demonstrate basic circuits (such as amplifiers, filters, and logic gate circuits).

Repair and modification

Temporarily build alternative circuits during repairs, or add new functions to old equipment (such as adding Bluetooth modules to speakers).

Small batch production

Some low-complexity products (such as LED controllers) can be directly mass-produced using standardized universal boards.

4. Limitations of universal circuit boards

Not suitable for high-frequency/high-speed circuits: lack of customized impedance control, which may cause signal interference.

Large size: manual layout is difficult to optimize space, and is not as compact as professional PCBs.

Low reliability: manual soldering is prone to cold soldering, and long-term stability is poor.

5. How to choose a universal circuit board?

Experimental verification → Choose a breadboard (no soldering, reusable).

Fixed circuit → Choose a perforated board (requires soldering, but more stable).

Complex function development → Choose a modular development board (such as the STM32 core board).

6. Future trends

The rise of open source hardware: Standardized platforms such as Arduino have lowered the threshold for electronic development.

3D printed PCBs: In the future, it may be possible to "print on demand" general-purpose circuit boards, further shortening the development cycle.

General-purpose circuit boards are the "test field" for electronic innovation, balancing flexibility and cost, and have become an essential tool for students and engineers. Although custom PCBs are irreplaceable in high-performance scenarios, general-purpose boards are still unmatched in the process of rapid iteration and creative implementation.