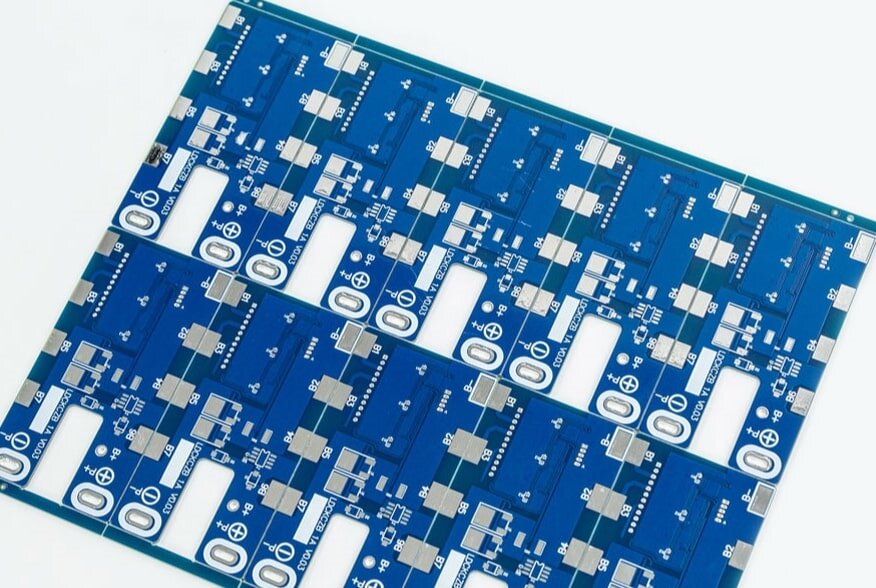

A blue PCB board refers to a printed circuit board with a blue solder mask coating on its surface. This protective film covers the underlying copper traces and insulating material. The main function of the solder mask is to prevent oxidation, solder bridging, and contamination during the assembly process. The blue color is not merely for decoration; it is achieved through a special pigment and resin formulation that must maintain optical transparency, chemical resistance, and mechanical adhesion.

Besides blue, PCBs also come in green, black, yellow, purple, red, and brown. Some manufacturers have even developed white, pink, and other colors of PCBs. While traditionally PCBs were predominantly green, nowadays PCBs come in a variety of colors, with blue being particularly favored by many engineers and designers. This choice is not only for aesthetic reasons; blue PCBs also offer several practical advantages that can expand the functionality of electronic devices and enhance their market competitiveness.

Comparison of blue pcb boards and Traditional PCBs: Traditional PCB boards are mainly green because green solder mask was the first to be widely used, and it is visually comfortable and easy to inspect the circuitry. However, with the diversification of industrial design and consumers' attention to product appearance, PCB colors have begun to break free from the constraints of green. Blue PCB boards are increasingly being used in high-end electronic products, computer hardware, and smart devices due to their unique visual effect, professional feel, and reliability.

From a technical perspective, there is no fundamental difference in performance between blue and green PCBs. The blue solder mask also provides:

Electrical insulation protection: preventing component short circuits or external environmental interference;

Moisture and dust resistance: improving the reliability of the board in high-humidity environments;

Soldering accuracy: helping solder accurately land on the pads, improving production efficiency.

At the same time, blue pcb boards also have advantages in visual inspection. The contrast between blue and copper traces makes it more intuitive for engineers to detect circuit defects or solder joint quality, reducing human error.

Why Blue PCB Board are Better

Engineers and manufacturers choose blue PCB board not only for their functionality but also for the added value they bring in terms of design, visibility, and branding.

1. Aesthetic Appeal

Blue PCB boards, with their vibrant color, leave a lasting impression, enhancing the product's attractiveness and showcasing innovation and quality, making them ideal for consumer electronics products visible to the end-user.

2. Medium Contrast

The blue solder mask provides good visibility for copper traces and silkscreen markings. Compared to darker colors, this makes assembly, debugging, and repair easier. While green still offers the highest contrast, blue strikes a balance between functionality and style, supporting reliable inspection and maintenance.

3. Branding and Personalization

By customizing blue PCB boards, brands can create a unique identifier in their products. For example, well-known motherboard manufacturers combine blue PCB boards with their brand logos and specific patterns, making their products instantly recognizable in the market.

Does color affect PCB performance?

In reality, the color of the PCB board does not directly affect its performance. Whether green, blue, black, or other colors, its electrical performance and signal transmission mainly depend on the material, design, and manufacturing process of the PCB board.

However, different colored PCB boards may have some subtle differences in some aspects. For example, black PCB boards, due to their darker color, may be more difficult to observe solder joints during the soldering process than lighter-colored boards, requiring higher soldering skill.

Blue PCB Boards

Application Areas of Blue PCB Boards

Blue PCB boards have a wide range of applications and are often used in situations requiring a calm and professional appearance or specific performance, such as medical electronics, aerospace, high-end instruments, communication equipment, and products requiring high solder joint reliability. This is because of their professional appearance, good contrast, and often containing components such as titanium, which improves high-temperature resistance, welding quality, and high-frequency signal transmission stability, making them especially suitable for LCD displays and situations where component differentiation is needed.

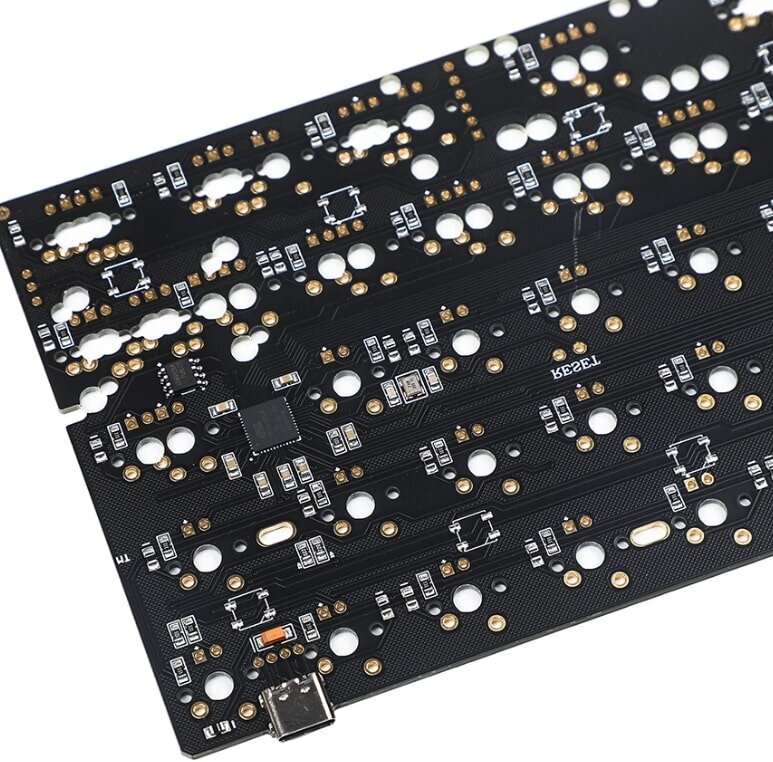

1. High-End Computer Hardware

In graphics cards, motherboards, and high-frequency storage devices, blue PCB boards have become standard for some manufacturers. It not only enhances the product's perceived quality but also creates a unique visual identity in product promotion. For example, some gaming graphics cards use blue PCB boards, combined with heatsinks and lighting designs, to create a sense of technology and professionalism.

2. Consumer Electronics

Small electronic devices such as smartwatches, tablets, and drones are increasingly demanding in terms of PCB design aesthetics. Due to its stable color and harmonious combination with materials such as metal and glass, blue PCB boards have become an ideal choice for these high-end products.

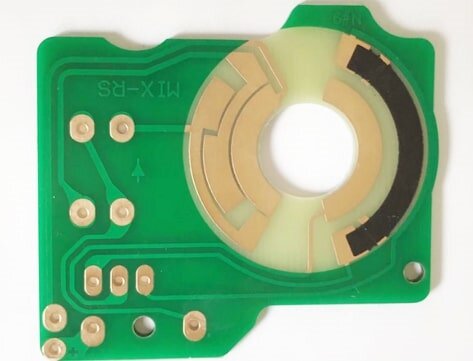

3. Industrial and Medical Equipment

In industrial control boards and medical equipment, the high visibility advantage of blue PCB boards is very significant. Engineers can more clearly observe the circuits and soldering conditions on the blue pcb board surface during debugging and maintenance, improving work efficiency.

4. Creative and Artistic Products

In recent years, some DIY electronics enthusiasts and artists have also incorporated blue PCBs into their creative designs. Whether it's electronic musical instruments, smart lighting devices, or technological art installations, blue PCB boards can give the works a unique visual appeal.

You can use blue circuit boards to enhance the aesthetics of your circuit boards. They are often used in high-end devices, and therefore high-quality materials are used in their manufacturing process. So, if you want your circuit board to look beautiful and intend to use it in a high-end device, then a blue PCB board might be the ideal choice for you.

Therefore, if you want both aesthetics and functionality, choosing a blue PCB boards is a wise decision.