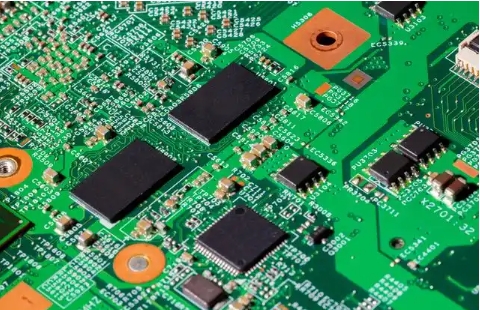

In today's highly integrated electronic era, complex PCB assembly has become a core link in the manufacturing of electronic products. With the continuous advancement of technology, the design of PCBs has become increasingly complex, not only containing a large number of electronic components, but also integrating multiple functional modules such as wireless communication, high-speed data processing and precision sensing. This complexity has posed unprecedented challenges to the PCB assembly process.

1. Technical challenges of complex PCB assembly

-Increased component density: Modern electronic products pursue miniaturization and lightweight, resulting in a sharp increase in component density on PCBs. This not only requires higher assembly accuracy, but also increases the interference between components and the difficulty of heat dissipation.

-High precision requirements: With the reduction of component size, the widespread use of tiny components such as 0201 and 01005 has put forward extremely high requirements for positioning accuracy and welding quality during the assembly process.

-Multilayer boards and 3D packaging: The introduction of multilayer PCBs and 3D packaging technology has made the circuit structure more complex and increased the difficulty of inter-layer alignment, interconnection and testing.

-Thermal management: The high heat problem caused by high integration requires that PCB design must consider effective heat dissipation strategies to avoid performance degradation or component damage caused by overheating.

-Signal integrity: High-speed signal transmission requires PCBs to have excellent electrical properties, including low loss, low noise, and stable impedance control.

2. Key steps in complex PCB assembly

-PCB design and manufacturing: First, PCB design is carried out according to product requirements, including component layout, wiring, stacking structure, etc., and then the finished PCB is produced through precise manufacturing processes (such as etching, electroplating, and lamination).

-Component procurement and inspection: Purchase the required components according to design requirements and conduct strict quality inspections to ensure the reliability and compatibility of the components.

-Component mounting: Automatic chip mounters are used to accurately mount components on PCBs through precise visual positioning systems. For tiny components, laser or X-ray technology may also be required for precise positioning.

-Reflow soldering: The mounted PCB is sent into the reflow soldering furnace, and through preheating, insulation, and cooling stages, the components and PCB form a good electrical and mechanical connection.

-Functional testing and debugging: Functional testing of the assembled PCB is performed, including electrical performance testing, signal integrity testing, thermal testing, etc., to ensure that the product meets the design requirements.

-Assembly and system integration: Assemble the tested PCB with other components (such as housing, display, battery, etc.) into a complete electronic product, and perform system debugging and verification.

3. Innovative solutions

-Advanced mounting technology: Introduce more advanced mounting equipment and technologies, such as laser positioning, AI-assisted mounting, etc., to improve mounting accuracy and efficiency.

-Intelligent detection technology: Use machine vision, deep learning and other technologies to realize automatic detection of component mounting and welding quality, and improve product quality and consistency.

-New welding process: Explore new welding processes such as low-temperature welding and selective welding to reduce thermal stress on components and improve welding quality and reliability.

-Thermal management innovation: Use new heat dissipation materials such as graphene and phase change materials to design efficient heat dissipation structures and improve the heat dissipation performance of PCBs.

-Modular design: Through modular design, complex PCBs are decomposed into multiple functional modules, simplifying the assembly process and improving production efficiency and maintainability.

Complex PCB assembly is a key link in the manufacturing of electronic products. In the face of growing technical challenges, it is particularly important to continuously innovate and optimize the assembly process. By introducing advanced technologies, improving automation levels, and strengthening quality control and heat dissipation management, these challenges can be effectively addressed and electronic products can be promoted to a higher level. In the future, with the continuous integration of intelligent manufacturing and Internet of Things technologies, complex PCB assembly will usher in more innovation opportunities, providing strong support for the intelligence, miniaturization and efficiency of electronic products.