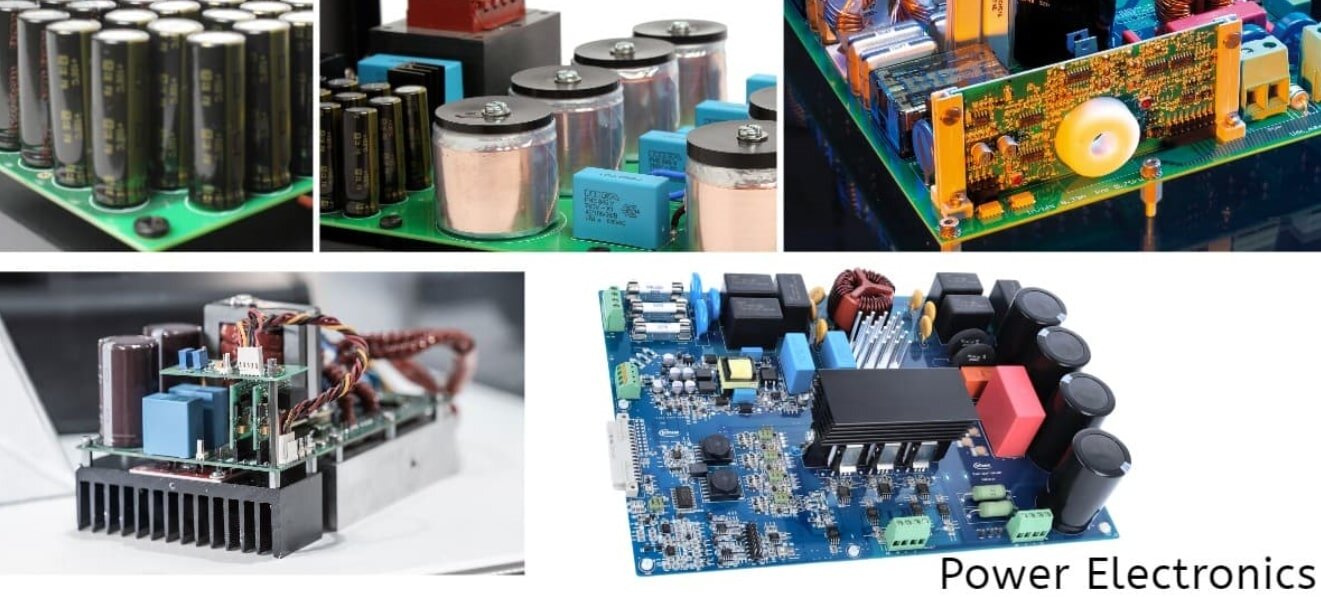

High current pcbs are specially designed printed circuit boards capable of carrying significantly higher currents than standard PCBs. This is typically achieved through thicker copper layers, wider traces, the use of special materials, and optimized heat dissipation design. They are widely used in high-power applications such as electric vehicles, industrial power supplies, and solar inverters to ensure stable and safe operation under high power demands.

High current pcbs are circuit boards capable of handling large currents. Their main characteristics include:

Thicker copper layers: typically 2oz, 3oz, 5oz, or even 10oz or more; Enhanced heat dissipation and thermal conductivity structures; Wider traces, thicker conductors or copper strips; Special structural techniques such as copper embedding, copper lamination, copper pillars, and thickened electroplated copper; and widespread use in high-current environments such as power conversion, motor drives, and battery management systems.

Compared to standard PCBs, high current PCBs place greater emphasis on current carrying capacity, thermal management, and mechanical strength.

Key Design Considerations for high current PCBs

Designing high current PCBs is not simple and requires careful planning. Here are some things you need to pay attention to:

Choosing the Right Trace Width and Copper Thickness

Trace width and copper thickness are crucial. They determine the amount of current the PCB can handle. If the trace is too thin, it may overheat; if the copper is too thin, it cannot effectively carry the current.

high current pcb

How to Calculate Trace Width

Start with the PCB you currently need to carry. Some in-line calculators can help. You enter the current, and it will tell you the correct trace width. Always remember that wider traces are better for high currents. They can reduce resistance and keep the PCB temperature lower.

Choosing Copper Thickness

Copper thickness is equally important. Thicker copper can carry more current. The standard is 1 ounce of copper per square foot.

But for high currents, you may need 2 ounces or even more. Thicker copper reduces the risk of overheating and improves the overall performance of the PCB.

Material Selection for high current PCBs

The substrate is the skeleton of the PCB, determining its heat resistance, mechanical strength, dielectric properties, and overall reliability. Commonly used substrates include:

(1) FR4 (glass fiber epoxy resin)

High current PCBs typically use high Tg (glass transition temperature) versions, such as Tg170 and Tg180.

High Tg materials are more stable at high temperatures and are less prone to softening, delamination, or deformation.

Suitable for most medium-to-high current and power conversion applications.

Advantages: Low cost, stable structure, and mature manufacturing process.

Limitations: Generally poor heat dissipation capacity, unsuitable for environments with extremely high heat flux density.

(2) Rogers and other high-frequency materials

Although high-frequency materials are typically used in RF or high-speed circuits, they also have value in high-current power supply applications:

Low dielectric loss and stable electrical performance

Good heat resistance (Tg > 200°C for many models)

Suitable for high-power, high-frequency power supplies, such as LLC, automotive power supplies, and high-voltage power modules

Applicable scenarios: High-frequency DC-DC converters, server power supplies, electric vehicle OBCs, etc.

(3) Metal Core PCB (MCPCB)

Common metal substrates:

Aluminum Core PCB

Copper Core PCB

The thermal conductivity of metal substrates is far superior to FR4:

Aluminum-based thermal conductivity is approximately 1–3 W/m·K

Copper-based thermal conductivity can reach over 200 W/m·K

Therefore, metal substrates can quickly dissipate the heat generated by electrical devices, making them suitable for:

High-power LED drivers

High-current power supplies

Automotive power modules

Industrial heating and motor drive systems

Especially in environments with high current and extremely high heat dissipation requirements, copper-based PCBs are one of the strongest heat dissipation solutions.

(4) Hybrid Stack-up

In some high-end applications, different materials are combined, for example:

Top layer: Rogers (for high speed or high frequency)

Middle/bottom layer: FR4 (providing structural support)

Local use of copper blocks or copper plates to customize heat dissipation paths

This structure allows the PCB to simultaneously possess → high-frequency performance + high current carrying capacity + high heat dissipation capacity.

Commonly used in: fast charging modules, automotive power supplies, inverters, power modules, etc.

The right materials can make or break your PCB. If materials cannot withstand current or heat, your PCB will fail. This is why choosing the right materials from the start is crucial.

Electronic devices generate heat during operation, causing the internal temperature to rise rapidly. If this heat is not dissipated in time, the device will continue to overheat, leading to component failure and decreased reliability. Therefore, good heat dissipation for circuit boards is essential. PCB heat dissipation is a critical aspect. Here are some PCB heat dissipation techniques:

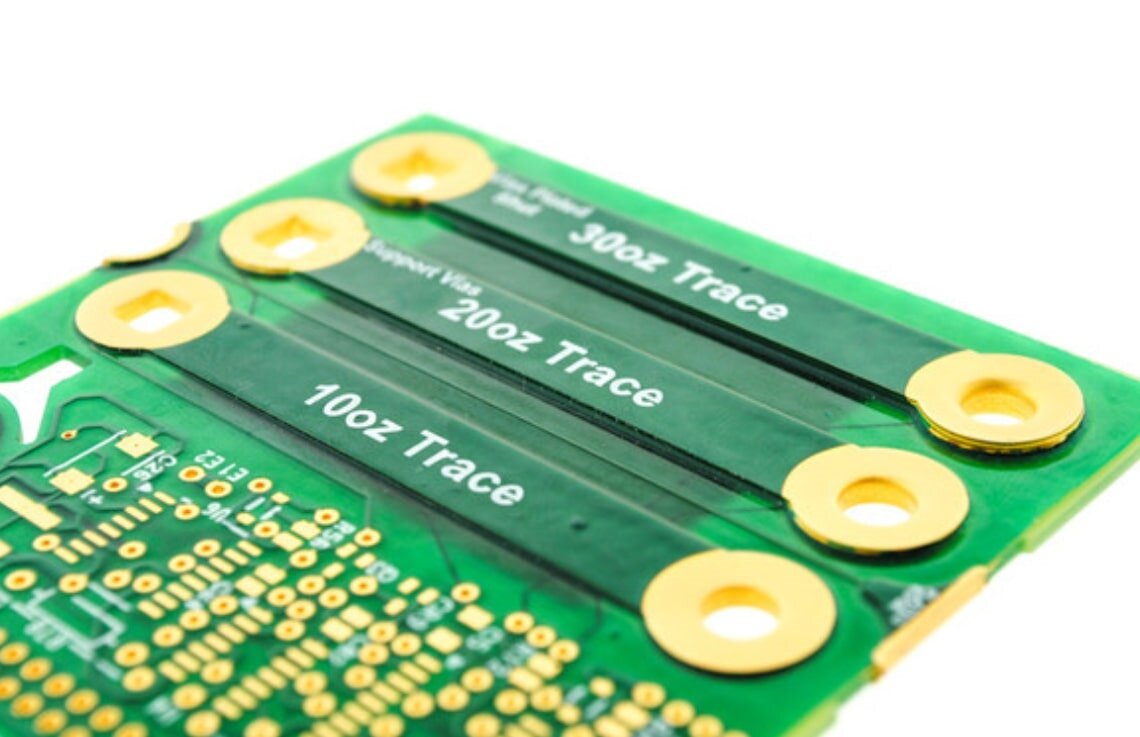

1. Increase Copper Thickness (Thick Copper / Heavy Copper) Copper thickness directly determines the conductor's resistance, temperature rise, and current carrying capacity, making it one of the most critical parameters when designing high current PCBs. The applicable ranges for different copper thicknesses are as follows:

1oz (35μm): Suitable for low-current lines in general electronic products, such as signal lines or low-power power supplies.

2oz (70μm): Suitable for medium to high current applications, commonly used in industrial control, small motor drives, power modules, etc.

3oz–6oz (105–210μm): Designed for high-current circuits, used in 10A–50A power converters, PFC, battery management systems, high-power drives, etc.

10oz and above (>350μm): Used for extremely high current or ultra-high reliability applications, such as replacing copper busbars in heavy-duty current paths, electric vehicle high-voltage systems, welding machines, power equipment, etc.

heavy copper pcb

As copper thickness increases:

Resistance decreases → Reduced power loss during current flow

Temperature rise decreases → Better overall heat dissipation

Resistance increases → Less prone to cracking or delamination under repeated high-temperature operation

Mechanical strength increases → More resistant to breakdown, better suited for high-current surges

Therefore, the greater the copper thickness, the stronger the current carrying capacity, and the more stable and reliable the circuit. However, the manufacturing difficulty and cost of thicker copper plates also increase, requiring a balance between performance and cost.

2. Increase Trace Width and Copper Pour: Wider traces result in better heat dissipation. Larger copper areas allow for rapid heat dissipation. Multi-layer copper pours improve heat conduction paths. High-current traces are typically kept short and straight to reduce heat generation points.

3. Enhance Heat Dissipation:

Heatsinks: Install aluminum or copper heatsinks on high-power components.

Air/Water Cooling: Increase forced convection with fans or use liquid cooling in high-end applications.

Heat Spreaders: Increase copper foil area to distribute heat over a wider area.

4. Material Selection:

High-Temperature PCB Materials: Upgrade to materials with lower dielectric constant (Dk)/dielectric loss (Df) and higher Tg (glass transition temperature) values (such as polyimide, ceramic).

5. Optimize Component Layout: Place temperature-sensitive components in warmer areas (such as the bottom of the device). Never place them directly above heat-generating components. Multiple components should be staggered on a horizontal plane. High current PCBs are one of the core foundations of modern power electronics. They require not only sufficient current carrying capacity but also excellent heat dissipation, structure, material selection, and manufacturing processes. With the continuous advancement of new energy vehicles, energy storage, fast charging, and industrial power supply technologies, the importance of high current PCBs will continue to increase.

If you are developing high-current related products:

Plan high-current paths as early as possible

Clearly define key indicators such as power, temperature rise, and peak current

Maintain thorough communication with PCB suppliers

Perform simulations when necessary to improve design reliability

High current PCB design is a technical skill, but even more so, it requires experience. The more attention you pay to design details, the more stable and safer your product will be.