High frequency PCB refers to a special circuit board with high electromagnetic frequency, used in the fields of high frequency (frequency greater than 300MHz or wavelength less than 1m) and microwave (frequency greater than 3GHz or wavelength less than 0.1M). It is used for coating microwave substrates Part of the process or special processing method for producing PCBs on copper sheets.

PCB high frequency circuit board refers to a special PCB with high electromagnetic frequency,used for high frequency (frequency greater than 300MHz or wavelength). Generally speaking, high-frequency PCB can be defined as PCB with a frequency above 1GHz. PCB substrate materials need to have excellent electrical properties and good chemical stability. As the frequency of power signals increases, the loss requirements for the substrate are very small,so the importance of high-frequency PCB boards becomes highlighted.

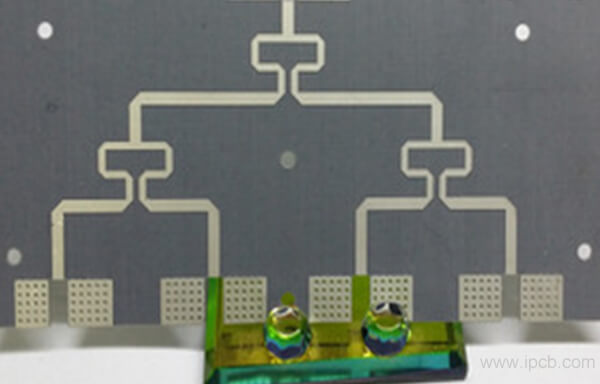

High frequency PCB

High-frequency PCBs using induction heating technology have been widely used in the communications industry, network technology, and high-speed information processing systems, meeting the requirements of many high-precision parameter instruments. Reliable high-frequency PCB provides great help in actual production. So, what are the advantages of such a powerful high-frequency PCB?

1.High efficiency

With a small dielectric constant, high frequency PCB losses are also small.Advanced induction heating technology can meet the needs of target heating and is very efficient.Of course,while focusing on efficiency, it also has the characteristics of environmental protection,which is very suitable for the development direction of today's society.

2.Fast

The transmission speed is inversely proportional to the square root of the dielectric constant,that is,the smaller the dielectric constant,the faster the transmission speed.This is the advantage of high-frequency PCB. It uses special materials, which not only ensures a small dielectric constant,but also maintains stable operation, which is very important for signal transmission.

3.High degree of supervision

High-frequency PCB is widely used in heat treatment of precision metal materials in various industries.It can not only realize component heating at different depths, but also concentrate heating according to local characteristics.Surface or deep,concentrated or dispersed heating can be achieved with ease.

4.Good tolerance

The dielectric constant and medium will have certain requirements on the environment, especially in the south,where humid weather will seriously affect the use of PCB.High frequency PCBs made from materials with extremely low water absorption can challenge this environment.At the same time,it also has the advantages of chemical corrosion resistance,moisture resistance,high temperature resistance, and high peel strength, allowing the high-frequency circuit board to exert powerful performance.