PCB board soldering is a method of joining components on a printed circuit board (PCB) with a metal that has a lower melting point than the other metals. It is the primary method for attaching electrical components to printed circuit boards (PCBs) and is essential for the PCB to function as intended. There are several types of solder materials, but for convenience, they are often combined to have lower melting points. The most common combination is a lead or tin alloy combined with brass or silver. A soldering iron then melts the metal, allowing it to act as a glue to connect the parts.

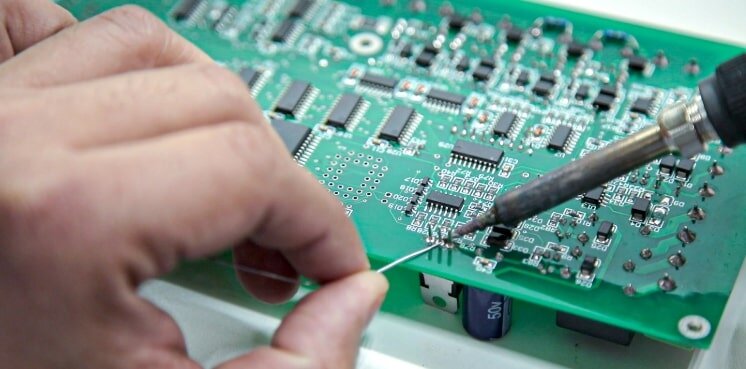

pcb board soldering

Those interested in learning how to solder PCBs should know that the parts are only joined as a single unit once the solder cools and solidifies; it never does before. An acidic substance called flux is also used during this process to prevent unwanted oxidation. While these are generally less efficient, several lead-free alternatives are now available for soldering, such as copper, brass, or silver, for safety and environmental reasons, and to reduce lead consumption.

Common pcb board soldering Methods

Hand Soldering

This is mostly used for prototyping, small-batch production, or repairs. Manual soldering with a soldering iron requires high operator skill and is suitable for soldering complex or specialized components.

Hand Soldering

Process Flow:

1. Tool Preparation: Prepare the soldering iron, solder wire, and flux, ensuring the soldering area is clean.

2. Heating the Solder Joint: Use a preheated soldering iron to heat the component lead and pad.

3. Applying Solder: Apply solder wire to the solder joint, melting the solder and wetting the pad and lead.

4. Removing Solder and Iron: After evenly coating the solder, remove the solder wire and soldering iron in sequence to form a good solder joint.

5. Residue Cleaning: If any flux residue is present, clean the solder joint with a cleaning agent.

Reflow Soldering

For surface mount components (SMDs). First, solder paste is applied to the pads, followed by placement of components. Finally, the reflow oven heats up, maintains a constant temperature, and cools down, melting and solidifying the solder paste. This ensures high soldering precision, making it suitable for precision electronic products such as mobile phones and computers.

Process Flow:

1. Solder Paste Printing: Solder paste (containing solder powder and flux) is precisely applied to the PCB pads using a stencil.

2. Key Equipment: Fully automatic printer + SPI (Solder Paste Tester).

3. Component Placement: The SMD machine picks up SMD components (resistors, capacitors, chips, etc.) and precisely positions them on the solder paste. 4. Reflow Process (Core Stage): The PCB passes through a multi-zone reflow oven, undergoing a precise temperature profile:

5. Preheating Zone: Slowly ramp the temperature from room temperature to 150°C to evaporate the solvent and prevent thermal shock.

6. Holding Zone: 150-190°C activates the flux, removes oxides, and maintains a uniform PCB temperature.

7. Reflow Zone: Peak temperature of 217-250°C allows the solder to completely melt, wet the pad and component pins, and form a metallurgical bond (lasting 30-60 seconds). Cooling Zone: Rapidly cools to <100°C to solidify the solder, forming bright solder joints (cooling rate >3°C/second). Once one side is completed, the process repeats for the previous side.

8. Cooling & Inspection: Forced air cooling solidifies the solder joints. AOI/X-RAY inspection is used to inspect solder joint quality (for bridging, cold solder joints, and offset).

Note: Reflow soldering and SMT (Surface Mount Technology) are closely intertwined in electronics manufacturing. Reflow soldering is a key process step in achieving SMT, while SMT is the technical foundation for reflow soldering.

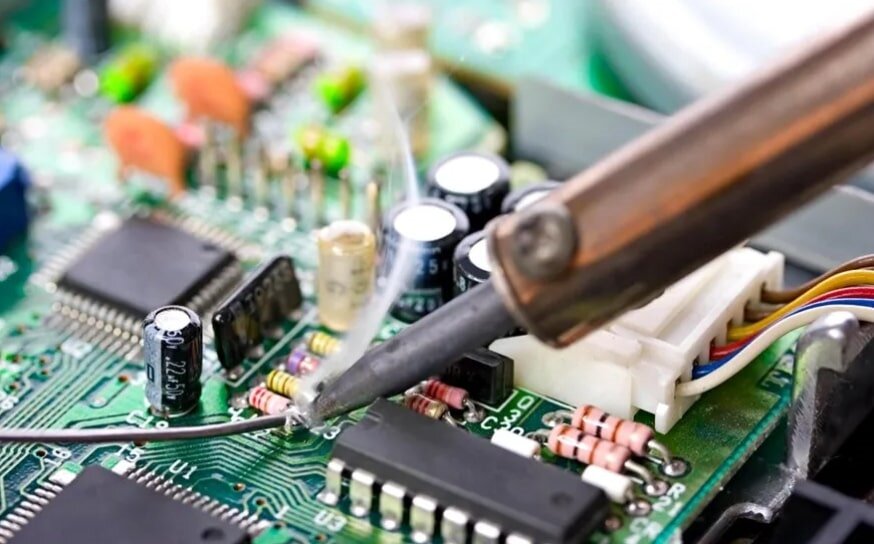

pcb board soldering

Wave Soldering

Wave soldering is a soldering process for attaching wiring or connecting components to a PCB, either manually or using a loading and unloading machine, depending on the assembly method. First, the entire soldering side of the module is wetted with flux, then preheated. Finally, solder paste is flowed over the wetted area, forming single or double solder peaks. After soldering, the entire module is cooled to reduce the thermal load on the PCB. Wave soldering is the standard method for soldering through-hole (THT) components that are subject to significant mechanical stress.

Process Flow:

1. Component Insertion: The leads of through-hole components (such as resistors, capacitors, and connectors) are precisely inserted into pre-defined holes on the PCB, either manually or using automated insertion equipment. 2. Flux Application: Use a spray, foam, or brush to evenly coat the bottom of the PCB with flux. This improves wettability, removes oxide layers, and enhances soldering reliability.

3. Preheating: The PCB enters the preheating zone and is heated to approximately 80°C to 130°C for 1-3 minutes. This step helps evaporate the solvent in the flux, activates the soldering function, and mitigates subsequent thermal shock, reducing the risk of PCB warpage.

4. Wave Soldering (Core Step): The PCB passes through a wave of molten solder (usually at a temperature of 250°C to 265°C) at a set angle (usually 5° to 7°), achieving rapid soldering between component pins and PCB pads.

5. Cooling and Setting: After soldering, the PCB is rapidly cooled by natural cooling or forced air cooling to solidify the solder joints and form a strong metal connection.

Note: Wave soldering typically requires the use of specialized fixtures (such as carriers or clamps) to ensure component fixation and soldering angles, improving soldering quality and yield.

pcb board soldering

The PCB (Printed Circuit Board) serves as the foundational platform for modern electronic products, carrying the responsibility for mounting electronic components and providing electrical connections. Throughout the electronics manufacturing process, soldering bridges the gap between components and the PCB, and its quality directly impacts product performance, stability, and lifespan. Therefore, understanding the principles, methods, and precautions of pcb board soldering is crucial for practitioners and those working in electronics manufacturing.

This is a brief introduction to pcb board soldering. We hope you find it useful and welcome your feedback.