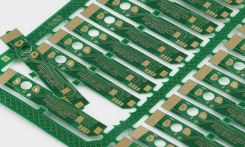

PCBs are core components of modern electronic products. The substrate cutting process during their manufacturing directly impacts product quality and production efficiency.

1. The Importance of PCB Substrate Cutting

PCB substrate cutting is a critical step in cutting large substrate materials (such as FR-4, aluminum, or ceramic) into the desired dimensions. The precision and quality of the cutting directly impact subsequent assembly, soldering, and the overall performance of the circuit board. Common substrate materials have varying physical properties, making the selection of the appropriate cutting method crucial.

pcb

2. Common PCB Substrate Cutting Techniques

The following are several mainstream PCB substrate cutting techniques, each with its own unique advantages and applicable scenarios:

2.1 Mechanical Cutting

Mechanical cutting is a traditional PCB substrate cutting method, typically using a high-speed rotating tool or saw blade.

Features:

Low equipment cost, suitable for small-batch production.

High cutting speed, suitable for substrates with simple shapes.

Possible burrs or microcracks, requiring subsequent polishing.

Applications: Suitable for thin, simple-design single- or double-sided boards. Precautions:

Tool wear can affect cutting accuracy and requires regular maintenance.

For high-density or multi-layer boards, mechanical cutting may cause delamination or damage.

2.2 V-Cut

V-Cut is a cutting method that pre-cuts a V-shaped groove into the substrate, facilitating subsequent manual or mechanical separation.

Features:

Suitable for panelized PCB production, improving production efficiency.

Cutting edges are relatively clean, suitable for PCBs with regular shapes.

Substrate thickness requirements are limited (usually 0.6mm or more).

Applications: Widely used in the mass production of consumer electronics products, such as PCBs for mobile phones and tablets.

Precautions:

V-groove design must be precise to avoid stress concentration that could cause substrate cracking.

Not suitable for complex shapes or ultra-thin substrates.

2.3 Laser Cutting

Laser cutting uses a high-energy laser beam to precisely cut substrates. In recent years, its application in high-end PCB manufacturing has become increasingly widespread.

Features:

High precision, suitable for complex shapes and micro PCBs. No mechanical stress, reducing the risk of substrate damage.

High equipment cost and slow cutting speed.

Suitable for: Flexible printed circuits (FPCs), high-frequency boards, or microelectronic devices requiring high precision.

Notes:

Laser parameters must be controlled to avoid burning the substrate material or excessively large heat-affected zones (HAZs).

High operating environment requirements, such as a dust-free workshop, are required.

pcb cutting

2.4 Punching Cutting

Punching cutting uses a die to punch out the substrate and is suitable for large-scale production.

Features:

High production efficiency, suitable for large-scale, standardized production.

High mold development costs, suitable for long-term, stable orders.

Potentially generates significant mechanical stress, affecting substrate quality.

Suitable for: Substrates with simple shapes and uniform thickness, such as aluminum substrates for LED light panels.

Notes:

Mold design must precisely match the PCB dimensions.

Not suitable for complex or multi-layer boards.

2.5 Waterjet Cutting

Waterjet cutting uses a high-pressure water jet mixed with abrasives to cut substrates. It is a lesser-used technology. Features:

No heat-affected zone, suitable for temperature-sensitive substrates.

Smooth cutting edges and high precision.

Complex equipment and high maintenance costs.

Standard PCB substrate cutting is an essential step in PCB manufacturing. Selecting the appropriate cutting technology requires a balance between cost, efficiency, and product quality. By understanding the advantages and disadvantages of different cutting methods and integrating them with actual production needs, companies can optimize production processes and enhance product competitiveness. In the future, as technology advances, PCB cutting will become even more precise and efficient, providing stronger support for the development of the electronics industry.