What is pcba and its components?

First: pcba is an abbreviation for pcb board + assembly. Simply put, an empty pcb board is loaded using an STM (Surface Mount Technology) and then assembled using DIP (Dual In-line Package) connectors. In layman's terms, a pcb is a circuit board without assembly; a pcb is a circuit board for soldering electronic components.

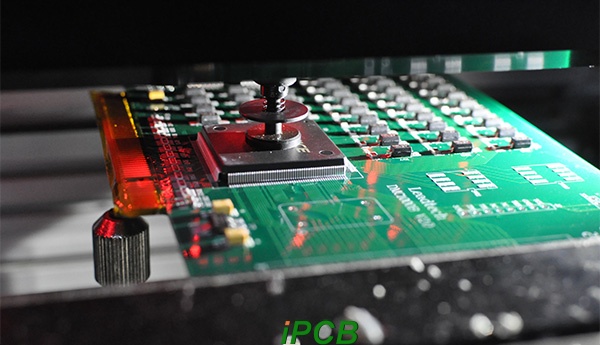

pcba primarily involves placing various types of electronic components onto an exposed pcb board. These small, delicate components, when correctly arranged and soldered, form the core functionality of the circuit board.

pcba Board Composition

A pcba board mainly consists of three parts: a printed circuit board (pcb), electronic components, and solder.

• Printed Circuit Board (pcb): Made of insulating material, it has conductive traces and pads for connecting electronic components. It is the support for electronic components and the provider of the circuit connections.

• Electronic Components: Including resistors, capacitors, transistors, integrated circuits, etc. These components are the core parts that realize various functions.

• Solder: A metal alloy that connects electronic components to the pcb, ensuring the correct connection of the circuit.

Key Characteristics of pcbs

High Density Capability:For many years, the high density of printed circuit boards (pcbs) has kept pace with the increasing integration of integrated circuits and advancements in mounting technology.

High Reliability: Through a series of inspection, testing, and aging tests, pcbs can be guaranteed to operate reliably for a long period (typically 20 years).

Designability:The various performance requirements (electrical, physical, chemical, mechanical, etc.) of pcbs can be met through standardized and regulated design. This results in shorter design time and higher efficiency.

Manufacturability:Modern management allows for standardized, large-scale, and automated production of pcbs, ensuring consistent product quality.

Testability:A comprehensive set of testing methods and standards has been established, allowing for the testing and evaluation of pcb product quality and lifespan using various testing equipment and instruments.

Assemblability:pcbs facilitate standardized assembly of various components and enable automated, large-scale mass production. Furthermore, assembling pcbs with other components can create larger parts, systems, and even complete machines.

Assemblability:pcbs are easy to assemble with various components and can be mass-produced automatically. Maintainability

Because pcb products and their assembled components are designed and mass-produced, these components are also standardized. Therefore, in the event of a system failure, replacements can be made quickly, conveniently, and flexibly, rapidly restoring system operation.

pcbs also offer other advantages, such as enabling system miniaturization, weight reduction, and high-speed signal transmission.

About PCBA

pcba is short for Printed Circuit Board Assembly. It refers to the entire process of mounting components onto a bare pcb using surface mount technology (SMT) and then through DIP (Dual In-line Package) assembly.

Note: Both SMT and DIP are methods of integrating components onto a pcb. The main difference is that SMT does not require drilling holes in the pcb, while DIP requires inserting the component's pins into pre-drilled holes.

SMT (Surface Mount Technology) is a surface mount technology that uses a mounting machine to mount tiny components onto a pcb. The production process includes: pcb positioning, solder paste printing, mounting by the mounting machine, reflow oven loading, and final inspection.

DIP, or "Dual In-line Package," refers to inserting components directly onto a pcb board. This method is used when components are too large for surface mount technology (SMT). The main production process includes: applying adhesive backing, component insertion, inspection, wave soldering, board finishing, and final inspection.

SMT (Surface Mount Technology) is a technology that mounts components directly onto the surface of a circuit board. Compared to traditional DIP (Dual In-line Package) technology, it significantly reduces component size and offers greater shock, vibration, and interference resistance. SMT also offers advantages such as more efficient space utilization and greater automation. Therefore, SMT has become one of the mainstream manufacturing technologies in the electronics industry.

DIP technology refers to Dual In-line Package technology. This technology connects components to the circuit board by passing their leads through holes. SMT components are larger than DIP components, limiting its development. However, DIP technology is still used in some applications that do not require high-density assembly.

Differences between pcb and pcba:

1. Appearance:

pcb: A single, clean board with only circuitry and no components.

pcba: Various components, such as resistors, capacitors, and chips, are soldered onto it, making it appear more complex and robust.

2. Functionality:

pcb: A basic framework without any electronic functionality. Its main purpose is to provide support and electrical connections for electronic components.

pcba: After components are installed, it has independent control and signal interfaces, making it a complete electronic component assembly board. It not only provides circuit connections but also enables more complex electronic device functions, such as data processing and signal transmission.

3. Manufacturing Process:

pcb manufacturing process: Covers steps such as substrate preparation, pattern drawing, conductive material printing, etching, drilling, and soldering (including surface treatment and subsequent processes). The focus is on the circuit board fabrication and basic structural construction. - pcba Manufacturing Process: In addition to the pcb manufacturing process, it adds component insertion and soldering steps, as well as more stringent inspection and testing procedures. The entire process is more complex and places higher demands on processes and equipment.

4. Different Testing Methods

pcb Testing: Since it does not have independent functions, it mainly focuses on process testing. It typically uses network analyzers to test the connectivity and impedance matching characteristics between circuits, checking for open circuits, short circuits, and other problems.

pcba Testing: Because it has independent functions, the testing process requires a signal source to stimulate it. Signal analyzers and other equipment are used to test its specific functions, such as checking whether the various performance indicators of the circuit board meet design requirements.

5. Application Focus

pcb: As the support and electrical connection carrier for electronic components, it is widely used in the early stages of electronic product manufacturing and is an indispensable basic component in electronic equipment manufacturing.

pcba: As a finished module, it is more directly used in various end products, directly determining the performance and stability of the end products.

Through this article, we have gained a clearer understanding of what pcba and its components are. As a leading pcba design and manufacturing service provider, ipcb is committed to providing customers with high-quality pcba solutions through sophisticated technology and continuous innovation. We consistently adhere to the principle of pursuing both quality and innovation to become a leader in the industry.