The process flow of PCBA OEM includes many important procedures such as PCB board process, component procurement and inspection, SMT mount assembly, DIP insertion, PCBA testing and so on. PCBA function test refers to the test of the target board to provide a similar running environment, so that it works in various design states, so as to obtain the parameters of each state to verify the function of the PCBA good or bad test method. Simply put, it is to load suitable excitation to the PCBA and measure whether the response of the output end meets the requirements. Generally, it refers to the PCBA function test after powering up the actual circuit board.

PCBA function test content voltage, current, power, power factor, frequency, duty cycle, position determination and other functional parameters of the measurement.

PCBA Function Test

PCBA function test contains:

1.Power supply part of the test - whether the power supply is working properly, test the voltage of each point - using a comparator or other

2.Interface test, whether there is Short & Open, resulting in abnormalities

3.IC module IC I/O read/write function test-Flash&EEPROM&CPU&SDRAM&Logic IC etc.

4.Special function test (different circuit board requirements are not consistent) - such as with infrared, the need for external receivers

PCBA function test involves analogue, digital, memory, RF and power circuits, usually with different test strategies. Testing involves a lot of actual critical functional paths and structural verification (to make sure there are no hardware errors) to make up for what was missed in the previous testing process. This requires that a large number of analogue/digital excitations are continuously applied to the PCBA, and an equally large number of analogue/digital responses are monitored and fully controlled in their execution. PCBA functional test systems and equipment come in many forms, each with its own advantages and disadvantages in terms of cost, time, effectiveness and maintainability.

iPCB PCBA function test is mainly divided into the following categories

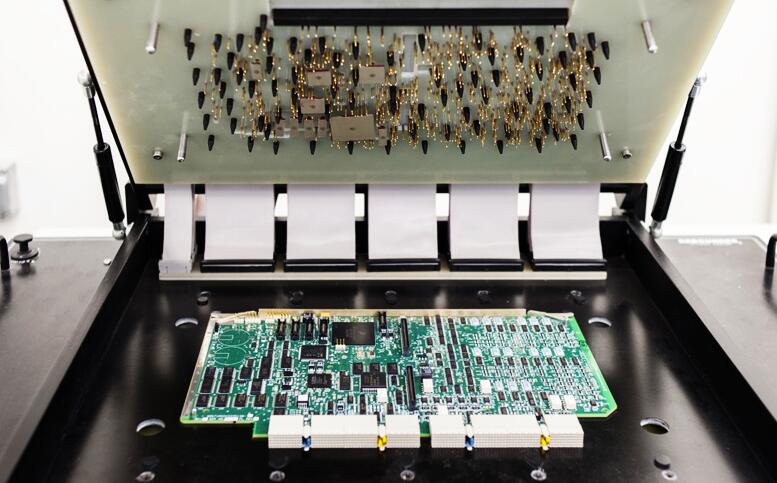

1.Manual test fixture

Manual test fixture is the use of Bakelite and acrylic to make a needle plate, the board to be tested, the input, output, power supply are led out, the use of artificial analogue input, artificial to confirm the correctness of the output or not.

Characteristics: cheap, manpower use more, slow test efficiency, test not ** product is not guaranteed!

PCBA Function Test

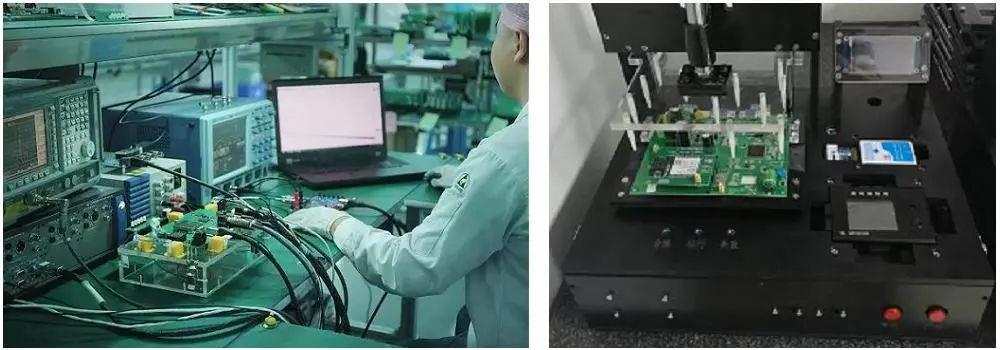

2.Microcontroller control function test

Make a clamping jig or pneumatic jig, and then lead the probe out.Connect the input, output, and power to the MCU circuit, and let the MCU automatically run the test programme to analogise the input and measure the correctness of the output.

MCU function test fixture mainly has the following parts:

(1) test fixture,the product's input and output interfaces lead out.

(2) MCU control board: the entire test process and test value judgement. Input and output control. Display control

(3) Signal source board: Provide all kinds of signal sources needed during the test.

(4) Relay board: switching various inputs and outputs.

(5) Measurement board: Measurement of the output part of the product, judge whether it is good or not.

(6) display module: display test results and display the test status, usually LCD and digital tubes

Features: MCU function test price is moderate, high test efficiency, good test quality, less human intervention. But the generality is not strong, generally only a machine with a fixture

3.Computer-controlled test system

The use of pneumatic or automated test structures on the production line,through computer control to test the quality of products.

Features: computer-controlled test fixtures are more expensive, fast testing,no human intervention, fully automatic testing.Good versatility, can be used for similar products.

PCBA function test is a necessary process, if completed correctly, it can prevent the product to avoid quality problems on the market to damage the brand reputation. Functional PCBA testing is required at the end of the manufacturing process to ensure that manufactured parts do not immediately fail or have a shortened lifespan.