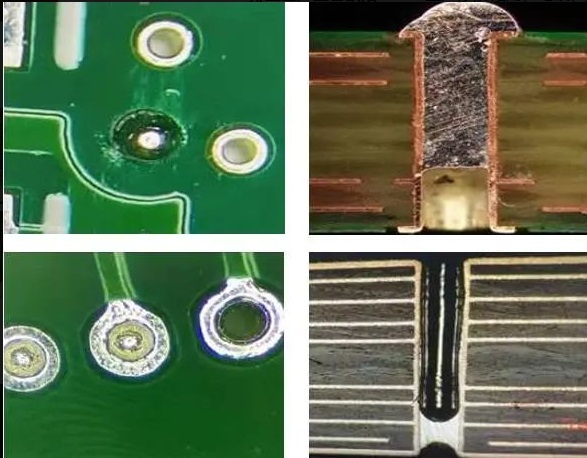

In the PCB and PCBA industry, "quality" is the core keyword that runs through the entire production process. From the etching of bare board circuits to the soldering and assembly of components, many key quality issues are hidden at a microscopic level that cannot be touched by the naked eye, such as the thickness of copper walls in PCB internal through holes, the porosity of PCBA solder joints, and the bonding state between component pins and pads. The "slicing" technology is the core means to uncover these microscopic mysteries and safeguard product quality.

In the context of the PCB industry, "slicing" is not commonly understood as "cutting fragments". It is a professional detection technique that analyzes the microscopic characteristics of materials and structures by preparing sample cross-sections and combining them with high magnification observation equipment. Simply put, it is like performing a "micro CT" on PCB/PCBA, visually presenting the hidden structures and defects inside.

1. Core classification of slicing: PCB bare board slicing and PCBA assembly slicing

According to the different detection objects, slices can be divided into two categories, with significant differences in their detection focus:

PCB bare board slicing: focusing on the structural quality of the substrate itself, such as internal circuits, through holes (PTH), blind buried holes, dielectric layers, etc., for "blank circuit boards" with unwelded components;

PCBA assembly slicing: For "finished boards" that have already soldered resistors, capacitors, chips, and other components, the core focus is on "solder joint quality" and component assembly reliability, such as solder joint voids, solder wetting status, and the bonding interface between pins and pads.

2. The production process of slicing: a rigorous process from "sampling" to "observation"

A qualified sliced sample needs to go through multiple precision processes, and any improper operation at any step may result in distorted test results. The core process is as follows:

Sampling: Based on the testing requirements (such as verifying the through-hole quality of a certain batch of PCBs, locating the failed solder joints of a certain PCBA), representative small-sized samples (usually with a side length of 5-10mm) are taken from the product to ensure that the sampling location covers the target testing area;

Inlaying: Place the sampled sample into a dedicated mold, inject liquid epoxy resin (or phenolic resin), and "wrap" the sample into a hard cylindrical or square "inlay block" by heating or curing at room temperature - the purpose of this step is to protect the sample from damage during subsequent grinding and facilitate handheld operation;

Grinding and polishing: By rough grinding (using 800-1200 grit sandpaper to remove surface impurities), fine grinding (using 2000-5000 grit sandpaper to refine the surface), and polishing (using diamond polishing agent), the cross-section of the sample is polished to a mirror smooth finish to ensure that the microstructure can be clearly presented;

Corrosion (optional): For some samples that require highlighting the structural hierarchy (such as the interface between the copper layer and the dielectric layer of a PCB), specialized chemical reagents (such as ferric chloride solution) will be used to slightly corrode the cross-section, enhancing the contrast between different materials;

Observation and analysis: Place the processed slices under a high-power microscope (optical microscope 200-1000 times, or scanning electron microscope SEM higher magnification) for observation, and use image analysis software to measure key parameters (such as through-hole copper wall thickness, solder joint void area ratio), and finally generate a detection report.

PCB slice analysis image

The reason why slicing technology has become a "quality standard" in the PCB industry is essentially because it solves the pain point of "microscopic defects that cannot be observed by the naked eye". Its value runs through the entire process from raw material inspection to finished product failure analysis, which can be developed from two dimensions: PCB bare board and PCBA assembly.

1. For PCB bare boards: Verify the compliance and reliability of the "substrate foundation"

As the "carrier" of electronic components, the quality of the internal structure of PCB directly determines the electrical performance and service life of subsequent PCBA. The core function of slicing is to "penetrate the surface layer and check whether the key structures that are not visible inside meet the standards":

Verify the compliance of design parameters: PCB design documents will clearly specify key parameters such as copper thickness (e.g. 35 μ m/70 μ m), dielectric layer thickness (e.g. 0.1mm), through-hole aperture (e.g. 0.3mm), and blind buried hole depth. By slicing, these parameters can be directly measured to determine whether they meet the design requirements - for example, if the thickness of the copper wall of the through-hole is insufficient, it can lead to a decrease in conductivity and even burn out due to excessive current during long-term use;

Troubleshooting production process defects: PCB production involves multiple processes such as etching, electroplating, and lamination, which can easily lead to hidden defects. Slicing can accurately detect:

Compression defects: whether there are bubbles or delamination between the dielectric layers (if not detected, subsequent welding at high temperatures may cause the substrate to "explode");

Electroplating defects: whether the copper layer inside the through-hole is uniform, whether there are "copper nodules" (protrusions causing short circuits in the circuit) or "pinholes" (holes causing conductivity interruption);

Etching defects: whether the edge of the circuit is "over corroded" (the circuit becomes thinner, the current carrying capacity decreases) or "residual copper" (excess copper foil causes short circuits in adjacent circuits);

Evaluate long-term reliability: By slicing and observing the cross-sectional changes of the PCB after reliability tests such as "thermal shock" (-40 ℃~125 ℃ cycle) and "wet heat aging" (85 ℃/85% RH environment), determine whether the bonding force between the dielectric layer and the copper layer has decreased, whether there are cracks in the through holes, and verify its service life in harsh environments.

2. For PCBA assemblies: safeguard the stability and safety of "solder joint connections"

PCBA is the finished product after PCB soldering components, and "solder joints" are the "hub" connecting components and substrates - if the solder joint quality is not up to standard, it can cause poor equipment contact, or serious safety accidents such as short circuits and fires. The core function of slicing is to dissect the microstructure of solder joints and determine whether the connection is reliable

Judging whether the quality of solder joints meets industry standards: Currently, the PCB industry generally follows IPC standards (such as IPC-A-610, IPC-J-STD-001), which have clear requirements for the porosity, wetting state, and morphology of solder joints. Through slicing, it is possible to visually inspect:

Void rate: If the internal void area of the solder joint exceeds 25% (IPC standard), it will cause an increase in contact resistance and poor heat dissipation, and long-term use is prone to solder joint overheating and failure;

Wetting state: whether the solder fully wraps the component pins and PCB pads ("non wetting" can cause virtual soldering, which is a common cause of "sudden crashes" in devices such as mobile phones and computers);

Solder joint morphology: whether there are problems such as "insufficient soldering" (insufficient mechanical strength, easy detachment of components), "bridging" (short circuit between adjacent solder joints), "pin floating" (unstable connection), etc;

Identifying the cause of PCBA failure: When a PCBA malfunctions (such as no signal from a certain chip or poor interface contact), slicing is a key means of "tracing the culprit". For example:

If a component frequently falls off, slicing can observe whether the interface between the solder joint and the pin forms an "excessive intermetallic compound (IMC)" - excessive IMC thickness can increase the brittleness of the solder joint, reduce the bonding force, and cause slight vibration to break;

If a short circuit occurs in a certain circuit, slicing can check whether there is a "solder bridge connection" or whether there is a "crack" in the internal circuit of the PCB due to high welding temperature (causing a short circuit in the circuit);

Optimizing welding process parameters: The slicing results can be used to infer whether the welding process is reasonable, helping enterprises improve production yield. For example:

If a large number of solder joint voids are found during slicing, it may be due to the rapid evaporation of solder flux in the solder paste (the heating rate of reflow soldering needs to be adjusted to slow down the evaporation of solder flux);

If insufficient solder wrapping is found on the component pins, it may be due to insufficient solder paste (requiring thicker steel mesh) or low soldering temperature (requiring adjustment of the peak temperature for reflow soldering).

3. The essential value of slicing: from "quality control" to "cost control"

The value of slicing technology goes far beyond "detecting defects" and runs through the quality control and cost optimization of enterprises

Quality control: In the incoming inspection (IQC), the PCB bare board provided by the supplier is checked for qualification through slicing; In process inspection (IPQC), monitor whether the production process is stable; In finished product inspection (FQC), ensure that the factory products meet customer requirements - avoid "defective products entering the market" from the source, and protect the brand reputation of the enterprise;

Cost control: By slicing, batch process defects (such as insufficient copper thickness of PCB through holes in a certain batch) can be detected in advance, and production can be stopped in a timely manner to avoid "whole board scrap" after soldering components, reducing rework and waste for enterprises;

Technological upgrade: For enterprises developing new types of PCBs (such as flexible PCBs and HDI high-density interconnect boards), slicing can help engineers observe the microscopic performance of new materials and processes, accelerating technological iteration.