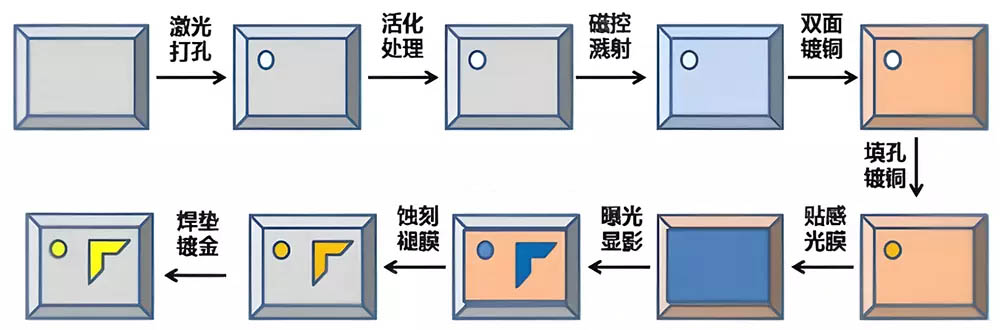

The Direct Plating Copper DPC process is a process for preparing high-density electronic packaging materials. This process is the main method for metal film deposition in microelectronics manufacturing. It mainly uses surface deposition processes such as evaporation and magnetron sputtering to metallize the substrate surface. First, titanium is sputtered under vacuum conditions, then copper particles, and finally electroplating thickening is performed. Then, the circuit is made by ordinary PCB process, and finally the thickness of the circuit is increased by electroplating/chemical plating deposition.

DPC process flow chart

Through the above steps, the DPC process of copper-clad ceramic substrates can prepare substrates with high thermal conductivity, excellent dimensional stability and reliable electrical performance. This substrate is often used in high-power electronic devices, radio frequency (RF) circuits, microwave devices, LED lighting and other fields to meet the requirements of high-performance electronic devices for thermal conductivity and signal transmission. The specific steps and parameters in the process may vary depending on the manufacturer and specific product, and need to be adjusted and optimized according to actual conditions.

DPC process

The copper-clad ceramic substrate (DPC) process has the following advantages:

1. Excellent thermal conductivity: DPC substrate uses ceramic as the base material, which has good thermal conductivity and can effectively conduct and dissipate the heat generated by high-power electronic devices, improving the reliability and performance of the device.

2. Superior high-frequency characteristics: DPC substrate has a lower dielectric constant and dielectric loss, and can achieve lower signal transmission loss in high frequency and microwave frequency bands, making it suitable for high-frequency and RF applications.

3. High-density packaging capability: DPC substrate has a higher line density and fine line width/fine line spacing capability, which can achieve a more compact circuit board layout and higher line density, which is conducive to miniaturization and integrated design.

4. Excellent mechanical properties: DPC substrate has high mechanical strength and hardness, can resist environmental stresses such as vibration, impact and thermal expansion, and improve the reliability and durability of the device.

5. Good dimensional stability: DPC substrate has a lower thermal expansion coefficient in a high temperature environment, can maintain good dimensional stability, and reduce the risk of mismatch and cracking caused by thermal stress.

6. Excellent welding performance: The copper film on the surface of the DPC substrate has good welding performance, which can achieve reliable circuit connection and welding.

7. High reliability and durability: The material and structural design of the DPC substrate make it have high reliability and durability, and can meet the requirements of harsh working environment and long-term use.

The DPC process of copper-clad ceramic substrate combines the thermal conductivity and excellent circuit performance of the ceramic substrate, which is suitable for electronic devices requiring high power, high frequency and high reliability, and provides an important material choice for the electronic packaging industry.

The copper-clad ceramic substrate (DPC) process is suitable for many fields and applications. The following are some fields suitable for using the copper-clad ceramic substrate DPC process:

1. Communication and radio frequency (RF) fields: DPC substrates are widely used in RF power amplifiers, antennas, filters, wireless communication equipment, etc. Its low dielectric loss and good high-frequency characteristics enable it to meet high-frequency signal transmission and RF power requirements.

2. Power electronics field: DPC substrates are suitable for manufacturing power electronic devices such as power amplifiers, inverters, motor drives, and electric vehicle chargers. Its excellent thermal conductivity and mechanical strength can effectively handle the heat and stress generated by high-power devices.

3. LED lighting field: The high thermal conductivity of DPC substrate makes it an ideal choice for LED lighting modules and packages. It can effectively dissipate heat and improve the luminous efficiency and life of LED circuit boards.

4. Automotive electronics field: DPC substrates are widely used in automotive electronics, such as power modules, battery management systems, and on-board communication equipment for electric vehicles. Its high temperature stability and durability enable it to meet the requirements of automotive environments.

5. High temperature application field: Due to the good high temperature stability and corrosion resistance of DPC substrate, it is suitable for high temperature applications such as aerospace, gas turbine control systems, etc.

In fact, the DPC process of copper-clad ceramic substrates can play a role in many other electronic devices that require high density, high thermal conductivity, and high reliability. The specific application needs and requirements will determine whether the DPC process is suitable.