X-ray is also called X-ray or X-ray, in our daily life,we often go to the hospital to do x-ray test on the use of x-ray, X-ray is a very short wavelength, high energy electromagnetic waves, penetrating ability is very strong. In the PCBA manufacturing and processing industry, we usually call X-ray inspection machine or X-ray inspection equipment, mainly is the use of X-ray principle of the product internal scanning and imaging, in order to detect defects within the PCBA products, such as: cracks,foreign objects and so on.

When the X-ray irradiation sample,the intensity of its passage is not only related to the energy of the X-ray,and at the same time with the material density and thickness of the sample data related to the lower density of the material and the thickness of the thinner the X-ray will be easier to pass. The principle of X-ray inspection is to use X-rays to irradiate the sample,through the image receiving and converting device will be X-rays through the intensity of grey scale contrast of light and dark difference to image.PCBA contains a variety of data, thickness varies, according to the size of the material density,generally divided into four categories:

1.By the material density of tin, lead or tin-lead alloy solder joints.

2.Metal and ceramic packaging shells, wires and chip bonding data.

3.Plastic sealing materials, silicon and other easily permeable materials.

4.Defects such as voids, cracks, and PCB vias. When the X-ray passes through the first and second types of data, the X-ray passes through less resulting in a higher grey value of the resulting image, when the X-ray passes through the third type of image is lower grey value, for the fourth type, the X-ray passes through the final bright image.

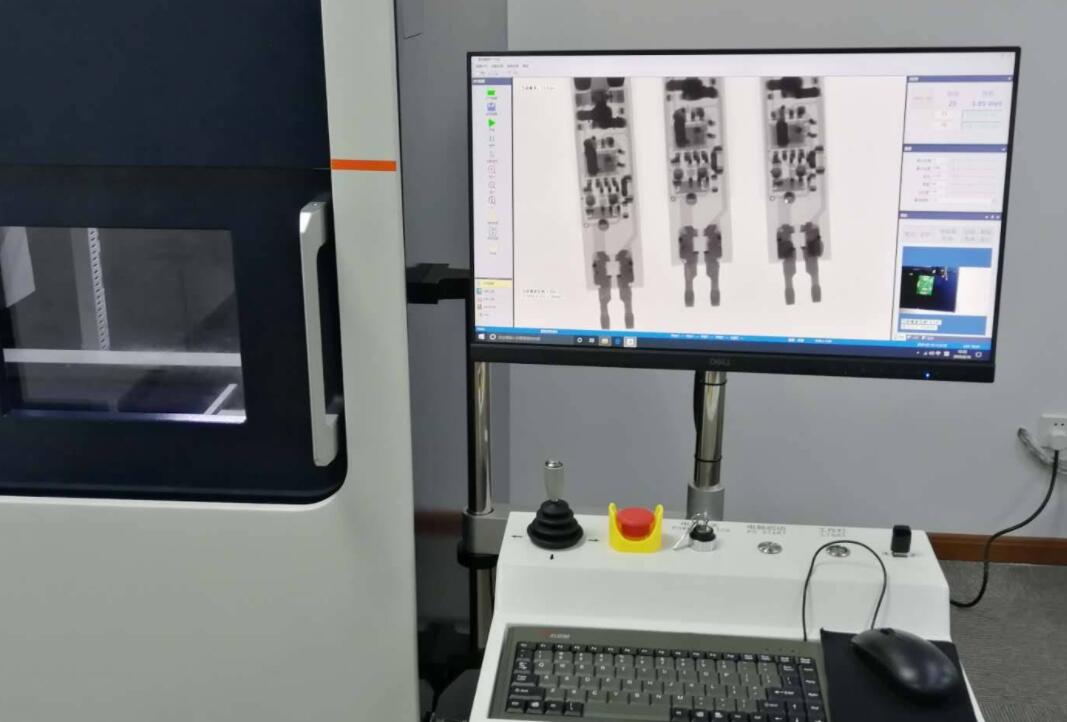

X-ray Inspection Equipment

So what role does X-ray inspection equipment play in PCBA manufacturing?

In recent years, the rapid development of electronic products, IC integrated circuit technology, the rapid development of more and more electronic products miniaturisation, lightweight, precision, antique books lead to electronic products inside the host board is getting smaller and smaller, and thus the components of such products are more inclined to packaging, resulting in a large number of ICs, BGAs, the demand for SMD, and such ICs are getting more and more pin, the more small, the more dense, and such as BGAs and CPUs and other types of ICs are hemispherical, and is located in the bottom position, through the human eye can not see the quality of reflow soldering, then X-ray inspection equipment what role in PCBA manufacturing? CPU and other types of IC are hemispherical, and is located at the bottom of the position, through the artificial eye can not see the quality of reflow soldering, antique books to check the soldering quality of this type of IC, must be used to X-ray machine inspection equipment.

The importance of X-RAY in the smt patch processing industry

Before the reflow soldering detection is basically carried out manually or AOI can be, can detect the daily IC (such as QFP / SOP) welding quality, because such IC pins exposed in the external, AOI can detect the welding quality, and with the pins in the bottom of the IC,the interior (such as BGA / QFN), the AOI and artificial naked eye can not be detected the welding quality, which need to rely on the use of comics X-RAY, through the X-ray penetration of the formation of light spots to determine whether the solder ball welding OK,there is no false soldering and other bad problems.

X-ray compared to other inspection equipment and the importance of the advantages:

1.Welding process defect detection coverage of 98%, especially X-ray on BGA, CSP and other solder joints hidden device inspection advantages.

2.Large detection range, wide coverage, early detection of good materials: If the PCBA is judged to break down the fault, suspected of PCB inner layer alignment cracks, X-ray can quickly check, or BGA / CSP and other materials in advance to detect the discovery of bad, to avoid defective materials into the production line, resulting in rework, waste of manpower and material resources, and so on.

3.Have a higher stability, reliability testing defect analysis, such as: internal solder ball soldering, air holes and bad shaping.

PCBA manufacturing to look at, BGA inspection is becoming more and more important, in order to ensure that this type of equipment to detect PCBA quality in the assembly process is not visible, X-Ray test is an important tool. This is because X-Ray inspection can penetrate inside the package and directly inspect the quality of the solder joints. As the packaging pipe of transistor product components is getting smaller and smaller, better X-Ray inspection is needed to ensure the need for miniaturised inspection of product components.