What is CEM-1 PCB material? So strange to most people, it is one of the base materials for printed circuit boards. It is a low grade in the PCB material industry and is only suitable for single sided PCBs, but it is widely used.

Some people would say that nowadays technology is advancing so fast that every electronic device is getting smaller and smaller. Why such a low grade material can be widely used.

Yes, the technology is getting higher and higher, but the average time, the components are also higher and assembled with more functions, which will allow more designers to use single sided PCB (Cem-1 material) to control the cost.

Single-sided PCBs (single layer PCBs) will greatly reduce design costs and this is the most important reason.

The standard CEM-1 material is a cellulose-based composite pcb material with a layer of fiberglass laminate (FR-4) on the surface. Normally CEM-1 has a milky white color.

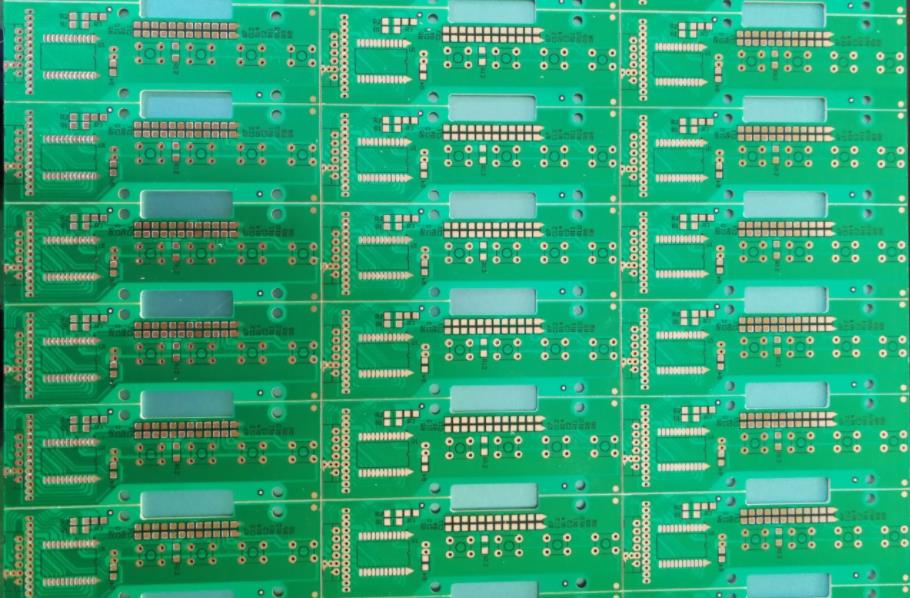

CEM-1 PCB

The characteristic feature of the material CEM-1 is the impossibility of real cash metalization through holes.Therefore, this material can only be used for the production of 1-layer printed circuit boards.

The standard CEM-1 meets the flammability class UL94-V0 as FR-4 material.Compared to FR-4,the mechanical properties of CEM-1 are slightly worse:CEM-1 is more fragile.The difference in dielectric constant and dielectric loss angle tangent between the two materials is not significant.

In this way, CEM-1 is a cheaper alternative to FR-4 materials for the production of 1. Layer printed circuit boards.

Technical parameters of CEM-1 PCB material

There are other better CEM-3 in the CEM PCB material family, let's look at the differentiation between CEM-1 and CEM-3.

CEM-1 composite material consists of a fiberglass fabric surface and paper core bonded with an epoxy resin. Mainly used in the printed circuit board industry. Compared to paper grades, it is easy to press, has excellent electrical performance and higher bending strength. CEM-1 has excellent mechanical and electrical performance with an impact force of 0.093”.

CEM-3 is very similar to FR4.Instead of woven glass fabrics, “fly” types are used. CEM-3 is milky white and very smooth.It is a complete replacement for FR4 and has a very large market share in Asia. It is a flame retardant epoxy laminate glass material that is typically used in double-sided and multi-layer PCBs for electronics.CEM-3 is a new type of printed circuit substrate material based on FR-4. In recent years, CEM-3 has been used to replace FR-4 in Japan, even exceeding the dosage of FR-4.

In the Led lighting market, most LED manufacturers use Cem1 as the base material. It can achieve the best balance between heat dissipation efficiency and PCB cost.

CEM-1 PCB

Extended Reading

Laminates are also known as base materials.The reinforcing material is impregnated with resin, covered with copper foil on one or both sides, and hot pressed to form a plate material called copper-clad laminate. It is the basic material for PCBs and is often called the substrate.When it is used in the production of multi-layer boards, it is also called core board (CORE).

Laminates are the basic material of the electronic industry, mainly used in the processing and manufacturing of circuit boards (PCB), which are widely used in television sets, radios, computers, computers, mobile communications and other electronic products.

Laminates industry has nearly a hundred years of history, which is a synchronous development with the electronic information industry, especially with the PCB industry, inseparable from the history of technological development. The development of laminates began in the early 20th century. At that time, laminates with resin, reinforcing materials and the manufacture of substrates, there has been encouraging progress.

Laminates commonly used in the following types:

1.FR-1 - phenolic cotton paper, this substrate is commonly known as bakelite (more economical than FR-2)

2.FR-2 - phenolic cotton paper.

3.FR-3 - Cotton paper (Cotton paper), epoxy resin

4.FR-4 - glass cloth (Woven glass), epoxy resin

5.FR-5--Glass cloth, epoxy resin

6.FR-6---Woolen glass, polyester

7.G-10---Glass cloth, epoxy resin

8.CEM-1--Cotton paper, epoxy resin (flame retardant)

9.CEM-2--Cotton paper, epoxy resin (non-flame retardant)

10.CEM-3--Glass cloth, epoxy resin

11.CEM-4--Glass cloth, epoxy resin

12.CEM-5--Glass cloth, polyester

13.AIN--Aluminum Nitride

14.SIC--Silicon Carbide

Comparison of PCB Material Specifications

CEM-1 is a cotton paper, epoxy resin (flame retardant) laminate pcb material.CEM1 board is a common fiberglass reinforced phenolic resin board that is generally used for low-cost applications. Its standard compressive strength should not be less than 50 MPa. However, the specific compressive strength value depends on the manufacturer and specification of CEM1 sheet. When purchasing CEM1 sheets, it is recommended to check the technical data sheet of the product or consult the manufacturer for accurate information. It is also important to note that CEM-1 PCBs must be used in accordance with the relevant safety practices to ensure that they will not crack or be damaged when subjected to loads.