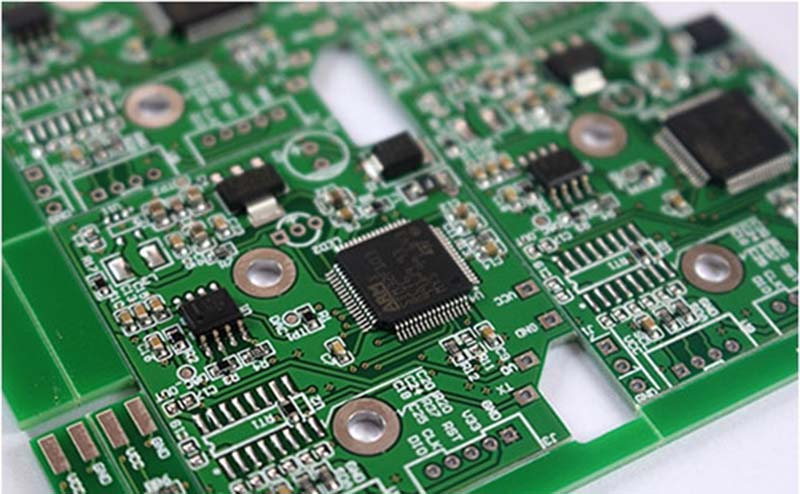

PCBA is the process of loading SMT onto an empty PCB and then carrying out DIP plug-in manufacturing, which involves many complex and complicated processes and some sensitive components. If the operation is not standardised, it will lead to process defects or component damage, affecting product quality and increasing processing costs. Therefore, in the PCBA patch processing process, must comply with the relevant operating rules and strictly in accordance with the requirements of the operation.

PCBA patch processing operation rules:

1.PCBA work area shall not have food or drink, no smoking, no work-related sundries, and keep the work table clean and tidy.

2.PCBA SMD processing process of welding surface should not bare hands or fingers, because the human hand secretion of grease will reduce the weldability, and easily lead to welding defects.

3. PCBA and component handling steps are minimised to prevent hazards. In assembly areas where gloves must be used, dirty gloves can cause contamination, so gloves should be changed as often as necessary.

4. Do not use grease to protect the skin or a variety of cleaners containing silicone resins, which may cause problems with the solderability and adhesive properties of the conformal coating. You can use a cleaning agent specially prepared for PCBA soldering surfaces.

5. EOS/ESD sensitive components and PCBAs must be labelled with the appropriate EOS/ESD symbol to avoid confusion with other components. In addition, to prevent ESD and EOS from endangering sensitive components, all operations, assembly and testing must be performed in a controlled environment. Assembly and testing must be done on a workbench where static electricity can be controlled.

6. Check the EOS/ESD bench periodically to make sure it is working properly (anti-static). Incorrect grounding methods or oxides in the grounding connection may cause various hazards to the EOS/ESD components. Therefore, the ‘third wire’ ground terminal connection should be specially protected.

7. Stacking of PCBAs is prohibited and may cause physical damage. The assembly work surface should be equipped with a variety of special brackets and placed according to the type.

In the PCBA mounting process, these operating rules should be strictly adhered to, the correct operation can ensure the end-use quality of the product, reduce component damage and reduce costs.