IHS research shows that by 2035, the 5G industry chain alone will generate $3.5 trillion in economic exports and create 22 million jobs. More importantly, 5G will create $12.3 trillion in sales activities across multiple industries worldwide, accounting for 4% of the total global sales activity.Which PCB material is more popular in the 5G era?

Polytetrafluoroethylene high-frequency PCB material

The material properties of high-frequency PCB board, including dielectric constant (DK), must be small and stable, consistent with the thermal expansion coefficient of copper foil, and have low water absorption rate. Otherwise, the dielectric constant and dielectric loss will increase and be affected by moisture. In addition, it must also have good heat resistance, chemical resistance, impact strength, peel strength, etc.

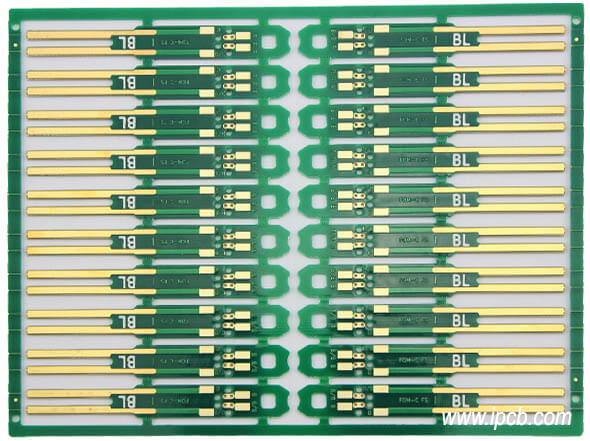

5G high-frequency PCB

Thermoplastic material polytetrafluoroethylene (PTFE) has the characteristics of high temperature resistance and working temperature up to 250 ℃. In a wide frequency range, the dielectric constant and dielectric loss are very low, and the breakdown voltage, volume resistance, and arc resistance are high. Therefore, polytetrafluoroethylene is an ideal PCB material.

Polytetrafluoroethylene (PTFE) can also be reinforced with various fillers such as glass fiber or ceramic materials to increase the thermal expansion coefficient of the material. This material has the low-temperature and electrical properties of polytetrafluoroethylene material, which is very suitable for the application of high-frequency millimeter wave plates.

LCP liquid crystal polymer has become a new favorite for mobile phone antennas

As an important component of wireless communication, antenna technology innovation is a key driving force for the development of wireless connectivity. With the approaching of 5G and the large-scale deployment of the Internet of Things, the role of antennas in 5G networks will become increasingly important, and the development prospects are very broad.

Taking smartphones as an example, due to the development of the industry and market, with the integration and high integration of mobile phone exterior design, the internal space of mobile phones is becoming smaller and smaller. It can be said that antenna design is very difficult.

More than 70% of the early built-in antennas were already connected to external antennas. At present, the soft board substrate of mobile phone antennas is mainly PI. However, due to the high dielectric constant and loss factor of PI substrate, strong moisture absorption, severe high-frequency transmission loss, poor structural characteristics, it cannot meet the material performance requirements of 5G.

With the development of 5G technology, industrial liquid crystal polymer (LCP) has become an ideal antenna material. It is a new type of high-performance special engineering plastic developed in the early 1980s. It generally exhibits liquid crystal characteristics in a molten state. It has excellent electrical insulation performance, higher dielectric strength and good arc resistance than general engineering plastics. Even if the continuous use temperature is between 200 ℃ and 300 ℃, its electrical performance will not be affected. Intermittent use temperature up to 316 ℃! Compared with PI and LCP materials, LCP material has smaller dielectric and conductor losses, is more flexible, and more sealed. Therefore, LCP materials have broad application prospects in the manufacturing of high-frequency devices. With the development of 4G towards high-frequency and high-speed 5G networks, LCP is expected to replace Pi as the new soft board technology.

For example, Apple's iPhone X used multi-layer LCD polymer antennas for the first time, while the iPhone XS/xmax/XR used multiple LCP antennas. In terms of upstream production, major manufacturers include DuPont, Tecona, Sumitomo, Formosa Plastics, Dongli, etc. For example, Sumitomo, one of the main manufacturers of LCP resin, is optimistic about the key applications of LCP resin in the 5G era. I believe that the application of LCP will become increasingly important in the future.

MPI modified polyimide 5G mobile phone antenna material Nova.

However, LCP has many advantages in practical applications. According to foreign media reports, analyst Guo Mingyi pointed out in his 2019 report on the new iPhone that given Apple's low bargaining power with LCP raw material suppliers and the lack of new LCP FPC board suppliers, Apple Mobile will cater to and promote 5G technology by combining LCP with the latest MPI (Modified PI) technology in 2019.

So what is MPI? Modified Pi is actually an improved polyimide antenna. MPI, as an amorphous material, has a wide working temperature range and is easy to operate under low-temperature pressed copper foil. Its surface can