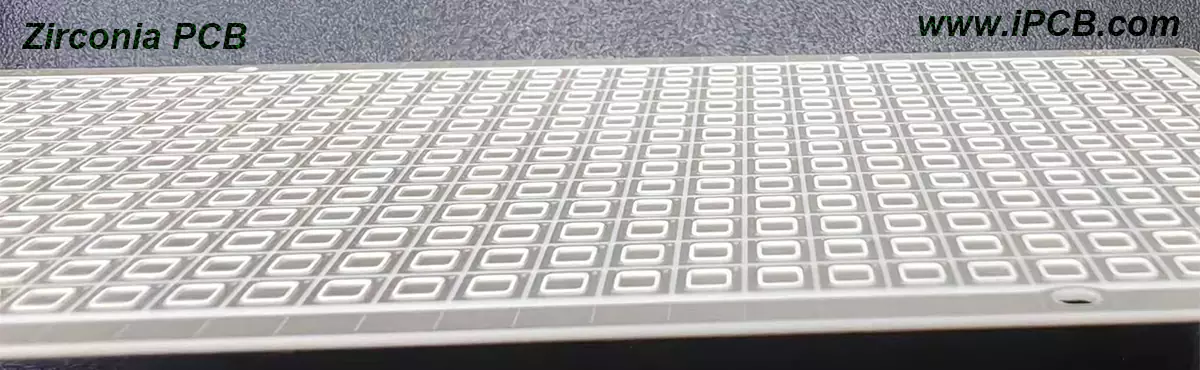

Product: Zirconia PCB

Style: Zirconia ceramic

Materials: Zirconia

Brand: Support customer customization

MAX temperature: 750 degree

Precision rating: P5

Stock: Available

Density: 6.05 g/cm3

Place of origin: China

Zirconia ceramic is white in color, while ZrO2 ceramic and Zirconia ceramic have excellent properties such as high melting and boiling points, high hardness, insulation at room temperature, and conductivity at high temperatures.

The molding of zirconia ceramic includes dry pressing molding, isostatic pressing molding, injection molding, hot die casting molding, casting molding, injection molding, plastic extrusion molding, colloidal solidification molding, etc. The most widely used ones are injection molding and dry pressing molding.

Parameters of zirconia ceramic substrate

Dielectric constant: 9.5-10.5

Thermal expansion coefficient: 6.5-7.5 ppm/℃

Insulation resistance: 10 ^ 12-10 ^ 14 Ω. cm

Heat resistance: Can be used for a long time in high temperature environments around 1000 ℃

Mechanical strength: flexural strength 1200 MPa, yield strength 900 MPa

Chemical stability: capable of working in acidic and alkaline environments, with excellent corrosion resistance

Thermal conductivity: up to 25 W/m-K or higher

Hardness: between 9-9.5, higher than traditional ceramic materials

Temperature range for use: -269 ° C to 850 ° C

Corrosion resistance: acid and alkali resistance, corrosion resistance can reach a pH value between 2 and 12

Zirconia ceramic PCB

Advantages of zirconia ceramic PCB

1. High frequency performance: The dielectric constant of zirconia ceramic circuit board is usually between 9.5-10.5, and the dielectric loss is around 0.0005. These data indicate that zirconia ceramic PCB have excellent performance in high-frequency signal transmission. For example, in a microstrip line experiment with a frequency of 2.4 GHz, the signal transmission loss using zirconia ceramic PCB was only 0.37 dB, while the signal transmission loss using FR4 circuit board was as high as 2.77 dB, indicating that the high-frequency performance of zirconia ceramic PCB is significantly better than that of FR-4 PCB.

2. High reliability: The high strength, high temperature resistance, and corrosion resistance of zirconia ceramic PCB can ensure the reliability of communication equipment in harsh environments. For example, in an experiment conducted in a high-temperature environment, the transmission loss of zirconia ceramic PCB was reduced by about 50% compared to FR4 PCB board. At the same time, zirconia ceramic PCB also exhibit strong corrosion resistance in corrosive environments.

3. High precision: The processing accuracy of zirconia ceramic PCB is very high, which can meet the requirements of small size, high density, etc. For example, in a microstrip antenna experiment, a microstrip antenna made of zirconia ceramic PCB has smaller size and higher performance compared to microstrip antennas made of conventional circuit board.

4. Good thermal stability: The thermal expansion coefficient of zirconia ceramic PCB is similar to that of silicon chips, making it less likely to damage the chip due to thermal expansion and contraction. For example, in an experiment conducted in a high-temperature environment, the transmission loss of zirconia ceramic PCB changed very little, indicating that it has good thermal stability in high-temperature environments.

Due to its excellent performance, zirconia ceramic PCB is commonly used in microwave communication equipment, radar systems, antenna arrays, RF modules, aerospace, missiles, satellites, aviation electronic equipment, aviation navigation systems, rockets, industry, medical, military and other fields that require high circuit performance.

Zirconia ceramic PCB is a high-performance circuit board material. The zirconia ceramic PCB produced by iPCB has reached a mature stage, and we can produce zirconia ceramic PCB with a line width/pitch of 0.1mm.

Product: Zirconia PCB

Style: Zirconia ceramic

Materials: Zirconia

Brand: Support customer customization

MAX temperature: 750 degree

Precision rating: P5

Stock: Available

Density: 6.05 g/cm3

Place of origin: China

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.