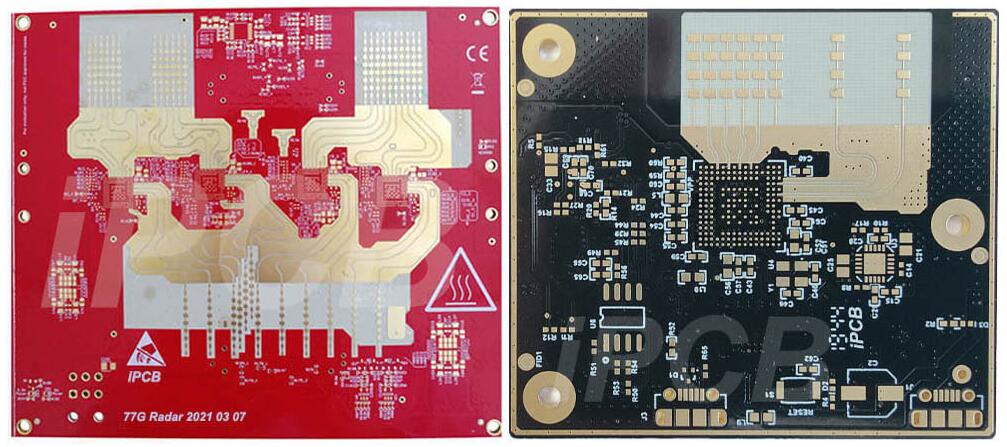

Millimeter wave band wireless signals are gradually being used in various fields, such as radar sensors for automotive advanced driver assistance systems (ADAS).77 GHz radar PCB sensors have proven to be quite effective in enhancing ADAS systems, and 77 GHz radar sensors are also key components for autonomous vehicles. But which PCB material is most suitable for ADAS and autonomous vehicles in the millimeter wave band? Unlike radio frequency circuits and microwave circuits with lower frequencies, millimeter wave frequencies have extremely stringent requirements for PCB materials. Rogers' RO3003 circuit board has all the characteristics required for millimeter wave band applications and will play an important role in the electronic systems for future autonomous vehicles, making highway driving safer.

For any high-frequency circuit design, keeping circuit losses to a minimum is a worthy goal, and keeping circuit losses low at millimeter-wave frequencies is even more important because signal power is smaller at millimeter-wave frequencies.

Now we discuss PCB circuit losses and their components and introduce key criteria to consider when selecting a PCB substrate to minimize circuit losses for a 77GHz radar PCB antenna.

Automotive millimeter wave radar

Circuit losses

For a 77GHz automotive millimeter-wave radar antenna, for example, the overall loss in the circuit is often described as insertion loss. Usually, the insertion loss of a circuit consists of four parts, namely conductor loss, dielectric loss, radiation loss and leakage loss. The first three methods all have a large impact, while the last one, leakage loss, is generally considered negligible even at millimeter wave frequencies.

conductor loss

Conductor loss is usually the most important of the four and is generally related to the choice of transmission line technology and technical parameters related to PCB materials (such as type of copper foil, skin depth and conductor width, etc.). The type of copper foil has a great impact on the conductor loss of millimeter wave circuits. Circuits with smooth copper foil surfaces have smaller losses than circuits with rough copper foil surfaces. For example, circuit materials with rolled copper conductors, which have a smoother copper foil surface, will have less loss, especially at 77 GHz, than standard electrolytic (ED) copper conductors with a rougher surface. The skin depth of copper (the depth of RF current in the copper-substrate interface) also affects conductor losses. Skin depth is affected by frequency, and as frequency increases, loss also increases. When the surface roughness of the copper conductor has the same or close to the same size as the skin depth, the surface roughness of the copper conductor will significantly increase the conductor loss of the PCB material.

The previous ROG blog once mentioned: Why can’t we continue to use familiar transmission line technologies, such as microstrip lines, in the millimeter wave frequency band? The structure of the microstrip line is simple. The top copper is the signal line, the bottom copper is the ground plane, and the middle is separated by a dielectric layer. It is undoubtedly the easiest for the design and manufacture of high frequency circuits. However, other transmission line formats, such as stripline and grounded coplanar waveguide (GCPW), are more advantageous at millimeter wave frequencies.

Radiation loss

Microstrip is a popular transmission line structure from RF to 30GHz, and its conductor loss is relatively low. Above 30 GHz, the radiation loss is often higher than the stripline and GCPW structures. Radiation loss is related to frequency and increases with the frequency. At the same time, it also depends on the dielectric constant (DK) of the PCB material, which decreases with the increase of DK.

The thickness of the PCB also has an impact on radiation losses, with thicker circuits having greater radiation losses. Clutter mode interference will also increase the radiation loss of millimeter wave circuits. To minimize interference from these spurious modes in millimeter-wave circuits, thinner dielectric materials are often combined with narrower conductors. For this reason, millimeter-wave circuits with shorter wavelengths tend to use thinner circuit materials, regardless of transmission line structure.

Dielectric loss

The dielectric loss of PCB materials is mainly related to the dissipation factor (Df) of the circuit material. This type of loss has a greater impact on certain circuit structures when more dielectric materials are used. For example, in stripline circuits using multiple layers of dielectric materials, dielectric losses are worthy of further study. It is also more noticeable in thicker microstrip and GCPW circuits compared to thinner circuits. Circuits with a solder mask green oil layer will also increase the dielectric loss of the PCB material, which is more obvious in GCPW than in microstrip circuits.

Material parameters at 77GHz

Circuit design and manufacturing requirements become more demanding at higher frequencies, because at, for example, 77 GHz, the signal wavelength is shorter and the signal power level is lower. However, if high-precision feature circuits can be fabricated and circuit materials can provide consistent properties, several different transmission line technologies can still be used at millimeter wave frequencies.

For example, low-loss stripline circuits at millimeter-wave frequencies are based on multiple consistent dielectric materials and conductor copper layers interconnected by plated through holes (PTHs). Each PTH adds a certain amount of capacitance and inductance to the circuit layer, thereby changing the performance of the circuit at millimeter wave frequencies, especially when the characteristics of the conductor layer and the dielectric layer are different.

Of course, at the 77GHz frequency, it is very important to minimize circuit losses because the signal power level is often very small. No transmission line technology is an inevitable choice for circuits at such high frequencies. However, the characteristics of circuit materials at mmWave frequencies can serve as a guide for selecting the best PCB materials at mmWave frequencies. While reducing circuit losses, six key circuit material properties are critical to enabling efficient, low-loss 77GHz millimeter wave circuits :

·Dk tolerance

·Circuit material Df

·Surface roughness of copper foil conductor

·Thermal stability coefficients of Dk and Df

·Water absorbency

·Glass weaving effect

At millimeter wave frequencies, when Rogers RO3003 PCB material is used to analyze the properties of these six materials, the advantages of the material at such a high frequency make it the best material choice in this frequency band. This may also explain why RO3003 laminate has become a widely used PCB material in 77 GHz and other millimeter wave circuit applications. Understanding these six key material properties and their relationship to electrical performance at millimeter-wave frequencies can help circuit design engineers seek optimal circuit performance at 77 GHz. Just as 2.4 GHz is associated with a wide range of wireless communication applications such as Wi-Fi, 77 GHz radar PCB has become the standard frequency for automotive millimeter wave radar.