What is AOI?

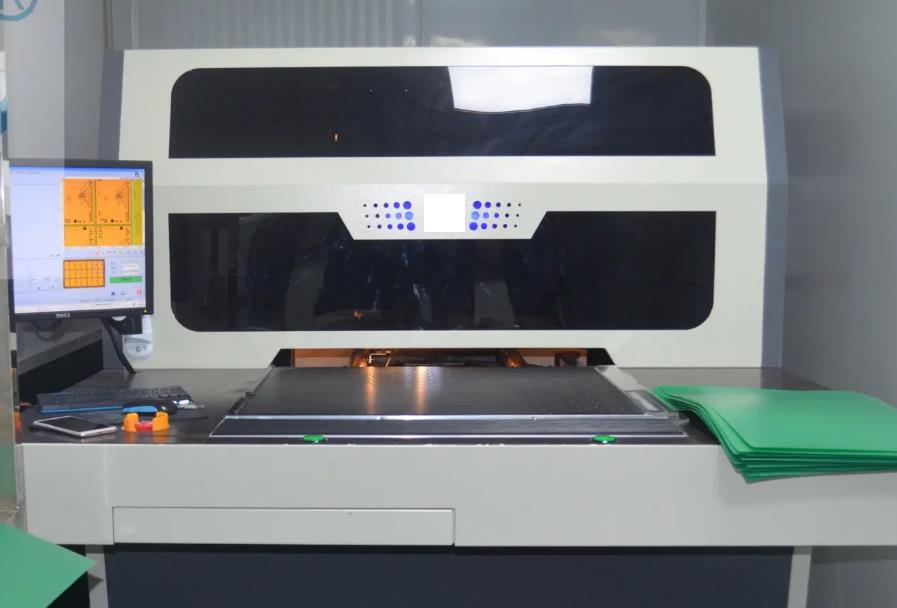

AOI (Automated Optical Inspection) is the Chinese name for Automatic Optical Inspection, which is a device based on optical principles to detect common defects encountered in welding production. AOI is a new test technology, but the development is rapid, many manufacturers have launched AOI test equipment. When the automatic inspection, the machine automatically scans the PCB through the monitor, collects the image, compares the tested solder joints with the qualified parameters in the database, detects the defects on the PCB through image processing, and shows/marks the defects through the display or the automatic sign for the maintenance personnel to repair.

AOI is mainly used to detect PCB (Printed Circuit Board) defects in various production processes, such as notches, protruding copper, short circuits, broken circuits, residual copper, pinholes, insufficient line width and line spacing, etc. It is an important stage to ensure the quality of PCB and to find out the problems of the previous process in a timely manner.

AOI uses high-speed and high-precision vision processing technology to automatically detect different kinds of mounting errors and soldering defects on PCBs. The range of PCBs can be from fine-pitch high-density boards to low-density large-size boards, and in-line inspection solutions can be provided to improve production efficiency and solder quality. Good process control is achieved by using AOI as a defect reduction tool to find and eliminate errors early in the assembly process. Early detection of defects will avoid sending bad boards to subsequent assembly stages, and AOI will reduce repair costs and avoid scrapping unrepairable PCBs.

AOI

The role of AOI

1. Scanning the PCB image through the optical

2. Compare with the standard PCB board (Cam data)

3.To find out the graphic defects on the PCB

What are the inspection items of AOI?

AOI equipment can detect rectangular and cylindrical electronic components on PCB, such as tantalum capacitors, coils, transistors, resistors, QFPs, SOICs, connectors, shaped components, whether there are: Missing, no solder, skew, tombstone, side stand, flip, wrong component, multi-solder, polarity reversal. AOI can be used to detect problems such as: excessive soldering, polarity reversal (Wrong polarity), continuous soldering, lead lift, lead defective, cracked soldering, solder bridge, insufficient solder, false soldering, cold soldering, foreign objects, breakage, bridging and so on.

Advantages of AOI

1. Simple programming

AOI is usually the automatically generated TXT auxiliary text file after the completion of the SMD machine programme design is converted into the required format of the file, from which the AOI obtains the position number, component series number, X coordinate, Y coordinate,component rotation direction of the five parameters, and then the system automatically generates the layout of the circuit to determine the position of each component parameters and parameters to be detected. After completion, the system will fine-tune the detection parameters of each component according to the process requirements.

2. Easy to operate

As AOI basically use a high degree of intelligence software, so it does not require operators to have a wealth of professional knowledge can be operated. With the development of technology, AOI test programme is fast and easy, reducing the production of a large number of test costs.

3. High fault coverage

Due to the use of high-precision optical instruments and highly intelligent test software,the usual AOI equipment can detect a variety of production defects, fault coverage rate of up to 80%.

4.Reduce Production Costs

As AOI can be placed in the reflow furnace before the PCB inspection, can be found in a timely manner by a variety of reasons for defects, rather than having to wait until the PCB after the reflow furnace to carry out testing, which greatly reduces production costs. This greatly reduces production costs. It also increases the through rate of back-end testing and reduces maintenance costs.

The disadvantages of AOI

1. Initial programming to establish the product file is more time-consuming.

2. The software design is not complete enough, for example: AOI can not clearly distinguish between electrode pin marks, scrapes and pollution.

3.AOI is only used to reduce the workload of visual inspection, but can not completely replace the manual visual inspection.

Above introduces what is AOI? And the role of AOI, advantages and disadvantages.