PCB = Printed Circuit Board, because a PCB is a circuit board composed of a single substrate, insulation, and copper foil, and then manufactured into a circuit using a printing and etching process, we call it a printed circuit board or circuit board. It is also known as PWB (Printed Wire Board) in the United States and the United Kingdom.

PCB is an important electronic component that serves as the support for electronic components within the PCBA board and also provides circuit connections for various electronic components. A circuit board connects all the components that need to work, such as capacitors, resistors, inductors, and IC chips, into a single unit, so we also refer to a printed circuit board as a motherboard or motherboard.

Almost every type of electronic device, from headphones, batteries, calculators, lights, household appliances, to computers, communication equipment, airplanes, satellites, cars, ships, medical equipment, etc., almost all products that require electricity use PCBs.

PCBA = PCB+Assembly, which means Printed Circuit Board Assembly. That is to say, optical boards without mounted components are PCBs, while PCBs with printed or assembled electronic components are PCBA.

PCB vs PCBA

The Origin of PCB

In 1925, Charles Ducas (the pioneer of addition method) in the United States printed circuit patterns on insulated substrates and successfully made conductors for wiring using electroplated pipes.

In 1936, Austrian Paul Eisler (the founder of subtraction) was the first to use PCB circuit board in radios.

In 1943, Americans applied PCB technology to military radios.

In 1948, the United States officially recognized the commercial use of PCBs.

In the 1950s, due to the solution of the adhesive strength and solder resistance issues of CCL and laminated boards, stable and reliable performance, and the realization of industrial large-scale production, copper foil etching became the mainstream of circuit board manufacturing technology, and Printed Circuit Board began to be widely used. Nowadays, PCB has occupied an absolute dominant position in the electronics industry. Start producing single panels.

In the 1950s, single-sided PCB production began.

In the 1960s, hole metallization of double-sided PCBs was achieved and large-scale production was achieved.

In the 1970s, multi-layer circuit board rapidly developed and continued to move towards high-precision, high-density, thin wire and small holes, high reliability, low cost, and automated continuous production.

In the 1980s, surface mount technology (SMT) gradually replaced plug-in circuit board and became the mainstream of production. The rapid development of ultra-high multi-layer PCBs and high-density interconnect HDI circuit boards.

In the 1990s, packaging technology further developed from flat packaging (QFP) to ball and roll array packaging (BGA), and PCBs began to move towards smaller circuits.

After entering the 21st century, high-density BGA, chip level packaging, and IC packaging substrates with organic laminate data as circuit board substrates have experienced rapid development.

PCB circuit board have evolved from single-layer PCB to double-sided PCB, multi-layer PCB, flexible PCB, R-FPCB, metal PCB, ceramic circuit board PCB, etc. And still maintaining their respective development trends. Due to the continuous development of high-density, high-precision, fine aperture, fine wire, small spacing, high reliability, multi-layer, high-speed transmission, lightweight, and thinness, the volume is constantly reduced, costs are reduced, and performance is improved. At the same time, in terms of production, we are developing towards improving productivity, reducing costs, reducing pollution, and regulating multi variety and small batch production. Making PCB circuit boards still maintain strong vitality in the future development of electronic devices.

What is the function of a PCB?

Before the emergence of circuit boards, the interconnections between electronic components were directly connected through wires to form a complete circuit. PCB provides mechanical support for fixing and assembling various electronic components such as integrated circuits. Implement wiring and power connections (signal transmission) or power insulation between various electronic components such as integrated circuits. Provide the required electrical characteristics, such as characteristic impedance.

After using PCBs in electronic devices, due to the consistency of similar Printed Circuit boards, errors in manual wiring are avoided, and electronic components can be automatically inserted or pasted, soldered, and inspected, ensuring the quality of electronic devices, improving labor productivity, reducing costs, and facilitating maintenance.

Circuit boards can provide mechanical support for fixing and assembling various electronic components such as integrated circuits, complete wiring and power connections or electrical insulation between various electronic components such as integrated circuits, provide required electrical characteristics such as characteristic impedance, provide solder mask graphics for automatic soldering, and provide identification characters and graphics for component insertion, inspection, and maintenance.

PCB can replace complex wiring and help achieve power connections between circuit components. This function not only simplifies the assembly and welding work of electronic products. It can also effectively reduce the workload of traditional pipeline wiring and alleviate the labor intensity of workers.

PCB reduces the volume of the entire machine and lowers the cost of the product. Effectively improving the quality and reliability of electronic devices. PCB can also achieve standardized practical pipelines, achieving production mechanization and automation.

Classification of PCBs

1. Classification by PCB application

Consumer PCBs: PCB used in toys, cameras, televisions, audio equipment, mobile phones, lights, household appliances, etc.

Industrial PCB (equipment type): PCB used in security, automotive, computer, communication machine, instrument, instrument, industrial controller, etc.

Military PCB: circuit board used in aerospace, space, radar, warships, military communication equipment, etc.

2. Classification by PCB substrate material

Paper based PCB: Phenolic paper based PCB, epoxy paper based PCB, etc.

Glass cloth based PCB: epoxy glass cloth based PCB, polytetrafluoroethylene glass cloth based PCB, etc.

Synthetic fiber PCB: epoxy synthetic fiber PCB board, etc.

Organic film substrate PCB: Nylon film PCB, etc.

Ceramic substrate circuit board.

Metal core based PCBs, such as iron substrates, aluminum substrates, and copper substrates.

Hydrocarbon PCB.

Ceramic powder circuit board.

PTFE, Teflon, Teflon, PTFE PCB.

3. Classified by PCB circuit board structure

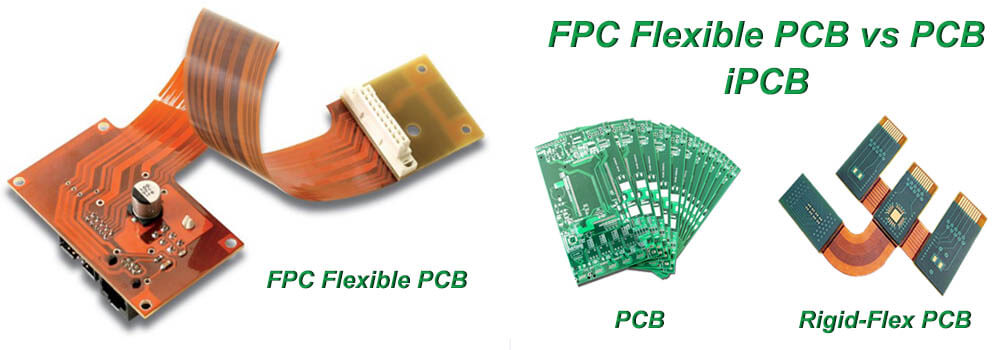

According to structure, it can be divided into rigid PCB, flexible PCB, and rigid-flexible PCB board.

rigid PCB, flexible PCB, and rigid-flexible PCB board

4. Classification by PCB layer

According to the number of layers, it can be divided into single panel, double-sided board, multi-layer board, and HDI board (high-density interconnect board).

Single panel -1-layer board

Single panel refers to a circuit board where wiring is only carried out on one side (soldering surface) of the circuit board, and all components, as well as component labels and text annotations, are placed on the other side (component surface).

The biggest feature of single panel is its low price and simple manufacturing process. However, due to the fact that wiring can only be done on one surface, it is difficult to do so and can easily lead to poor wiring. Therefore, it is only suitable for some relatively simple circuits.

Double sided board - 2 layer PCB

Double panel wiring is carried out on both sides of the insulation board, with one side serving as the top layer and the other side as the bottom layer. The top and bottom layers are electrically connected through via holes.

Usually, components on -layer circuit board are placed on the top layer. However, sometimes in order to reduce the size of the circuit board, components can also be placed on both layers. The characteristics of double-layer boards are moderate price and easy wiring, making them a commonly used type in conventional PCBs.

Multilayer PCB circuit board

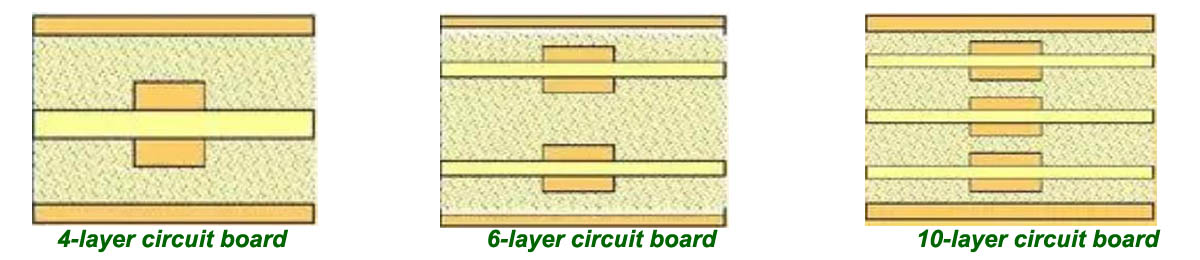

A PCB with two or more layers is collectively referred to as a multi-layer circuit board. In addition to the top and bottom layers of the PCB, multi-layer boards also have circuit wiring on the inner layer. Currently, the commonly used multi-layer PCBs are typically 4 to 20 layers or less.

HDI circuit board

HDI means high-density interconnection, and HDI circuit board refers to a type of PCB with a relatively high circuit distribution density that uses micro blind and buried hole technology. Currently, almost all PCBs used in mobile phone motherboards are HDI circuit boards.

Structure of PCB

PCB mainly consists of Copper Clad Laminates (CCL), Prepregs (PP sheets), Copper Foil, Solder Mask, and Character Layer. At the same time, in order to protect the exposed copper foil of the copper wires running through the circuit board and ensure the welding effect, it is also necessary to perform surface treatment on the PCB to prevent copper foil oxidation.

Composite Copper Foil Laminate (CCL)

CCL abbreviated as Composite Copper Foil or Copper Clad Laminate, is a product of fiberglass cloth and copper foil pressed together using epoxy resin and other fusion agents. Copper clad board is the basic material for manufacturing PCBs, which is a composite material composed of a dielectric layer (resin, fiberglass) and a high-purity conductor (copper foil).

It was not until 1960 that professional manufacturers used formaldehyde resin copper foil as a substrate to produce single-sided PCBs, which were then put into markets such as record players, recorders, and video recorders. With the rise of double-sided through-hole copper plating manufacturing technology, heat-resistant and size stable epoxy glass substrates have been widely used to this day. The commonly used ones now include FR4, FR1, CEM3, ceramic plates, and PTFE plates.

At present, the most widely used PCB made by etching method is selectively etched on copper foil to obtain the required circuit graphics. Composite copper foil mainly provides three functions on the entire PCB: conductivity, insulation, and support. The performance, quality, and manufacturing cost of PCBs largely depend on the composite copper foil board.

Fiberglass cloth is one of the raw materials for copper-clad laminates, woven from fiberglass yarn, accounting for approximately 40% (thick plate) or 25% (thin plate) of the cost of copper-clad laminates. Fiberglass yarn is made by calcining raw materials such as silica sand in a kiln into a liquid state. It is then pulled into ultra-fine glass fibers through extremely small alloy nozzles, and hundreds of glass fibers are twisted into fiberglass yarn. The construction investment of kilns is huge, usually requiring billions of funds, and once ignited, production must be uninterrupted 24 hours a day, resulting in huge exit costs.

Prepregs

Semi cured sheet, also known as PP sheet, is one of the main data in the production of multi-layer boards, mainly composed of resin and reinforcement data. Reinforcement data is divided into several types, such as glass fiber cloth (referred to as glass cloth), paper-based and composite materials.

The semi cured sheets (bonding sheets) used in the production of multi-layer PCBs mostly use glass cloth as reinforcement data. The thin sheet data made by impregnating the processed glass cloth with resin adhesive and then pre drying it through heat treatment is called a semi cured sheet. Semi cured sheets will soften under heating and pressure, and will solidify after cooling.

Due to the different number of yarn strands in the warp and weft organization lengths of glass cloth, attention should be paid to the warp and weft directions of the semi cured sheet during cutting. Generally, the warp direction (the direction of glass cloth curling) is extracted as the short side direction of the production board, and the weft direction is the long side direction of the production board to ensure the flatness of the board surface and prevent the production board from twisting and deforming after being heated.

Structure of PCB

Copper foil - circuit layer

Copper foil is a thin, continuous layer of metal foil deposited on the substrate layer of a circuit board. As a conductive material of a PCB, it is easily adhered to the insulation layer and etched to form a circuit pattern.

Common industrial copper foil can be divided into two categories: rolled copper foil (RA copper foil) and electrolytic copper foil (ED copper foil).

Rolled copper foil has good ductility and other characteristics, and is the copper foil used in the early soft board process.

Electrolytic copper foil has the advantage of lower manufacturing costs compared to rolled copper foil.

Copper foil: Copper foil is the raw material that accounts for the largest proportion of the cost of copper-clad laminates, accounting for about 30% (thick plate) or 50% (thin plate) of the cost of copper-clad laminates. Therefore, the price increase of copper is the main driving force for the price increase of copper-clad laminates.

Solder mask layer

The solder mask layer refers to the part of a PCB that has solder mask ink.

Solder resist ink is usually green, with a few using colors such as red, black, and blue. Therefore, in the PCB industry, solder resist ink is often referred to as green oil or green paint. The solder resist layer is the permanent protective layer of the PCB, which can prevent moisture, corrosion, mold, and mechanical scratches. It can also prevent parts from being soldered to incorrect places.

Character layer

Characters are the text layer, which is a layer above the solder mask layer in circuit board printing. It can be omitted and is generally used for annotation.

Usually, in order to facilitate the installation and maintenance of PCBA, the required logo patterns and text codes are printed on the upper and lower surfaces of the PCB board, such as component labels and nominal values, component outline shape and manufacturer logo, production date, etc.

PCB surface treatment

The "surface" referred to here refers to the connection points on a PCB that provide electrical connections between electronic components or other systems and circuits on the PCB, such as solder pads or contact connections. Bare copper itself has good weldability, but it is easily oxidized and contaminated when exposed to air, so a protective film should be covered on the surface of bare copper.

Common PCB surface treatment processes include lead spray tin, lead-free spray tin, organic Solderability Preservatives (OSP), gold sinking ENIG, silver sinking, tin sinking, and gold plated fingers. With the continuous improvement of environmental regulations, lead spray tin technology has gradually been banned. Currently, almost all circuit boards produced by PCB manufacturers comply with the RoHS process, and some printed circuit boards comply with the halogen-free PCB process.

What is PCB as we have explained above? After the adoption of PCB in electronic products, due to the consistency of circuit board, errors in manual wiring can be avoided, and automatic insertion or installation, welding, and inspection of electronic components can be achieved, thereby ensuring the quality of electronic products, improving labor productivity, reducing costs, and facilitating maintenance. Therefore, PCB has become an indispensable component in today's electronic products.