1.What is an HDI circuit boards?

HDI circuit boards (High-Density Interconnect Printed Circuit Boards) are a type of PCB that utilizes microvias and buried vias to achieve high-density routing.Due to their high wiring distribution density, HDI boards can accommodate more circuitry within a limited PCB space. The structure of an HDI board includes both inner and outer layers of circuits, and reliable interconnections between multiple layers are achieved through processes such as laser drilling, via filling, and electroplating.

Depending on the complexity of their design and application,HDI boards can be categorized into different levels, such as first-order (1+N+1), second-order (2+N+2), and third-order (3+N+3) HDI, to meet various design requirements. Compared to traditional PCBs,HDI pcb boards are characterized by high integration, thinness, and miniaturization, making them widely used in modern high-end electronic products such as smartphones, tablets, medical devices, and military electronics.

2.Distinguish between first-order, second-order, and third-order HDI circuit boards are detailed as follows:

(1)First-Order HDI: Involves one lamination process followed by laser drilling, then a second copper foil lamination, and another laser drilling. This constitutes a first-order HDI.

(2)Second-Order HDI: After the initial lamination and drilling, an additional copper foil lamination is followed by laser drilling. A second copper foil lamination is then applied, and a second laser drilling process occurs. The order is determined by the number of laser drilling operations: a single laser drill indicates first-order, while two laser drills indicate second-order.

(3)Within second-order HDI, there are two main types: stacked vias and staggered vias.

Eight-Layer Second-Order Stacked Vias: Layers 3-6 are laminated together first, then layers 2 and 7 are laminated, followed by the first laser drilling. After laminating layers 1 and 8, a second laser drilling is performed. Due to the stacking of vias, this process is more complex and incurs higher costs.

Eight-Layer Second-Order Staggered Vias: Although this method also requires two laser drilling processes, the vias are not aligned, resulting in a less complex and costly process.

For third-order and higher HDI circuit boards, the same principles apply, with additional laser drilling processes corresponding to higher orders.

3.Characteristics of HDI circuit boards:

(1) High integration: A higher level of circuit integration is achieved by adding denser vias and finer lines.

(2) High precision: The manufacturing process is precise and can provide higher positioning accuracy to meet the needs of high-performance equipment.

(3) Thermal management: The design allows for better heat dissipation and management, maintaining the stability of electronic equipment and extending its life.

(4) High reliability: The manufacturing process is strict and the quality control standards are high, providing high reliability in various environments.

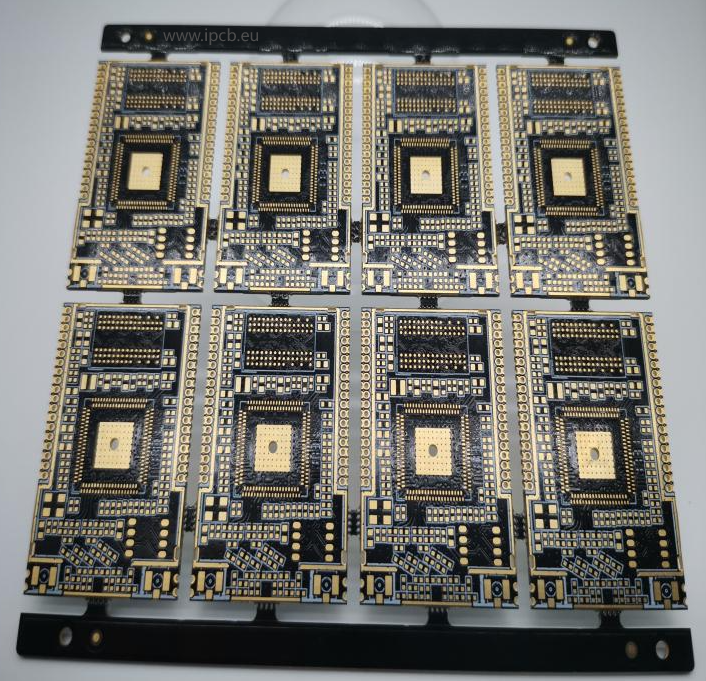

HDI PCB Assembly

4.How to meet the needs of highly integrated electronic PCB

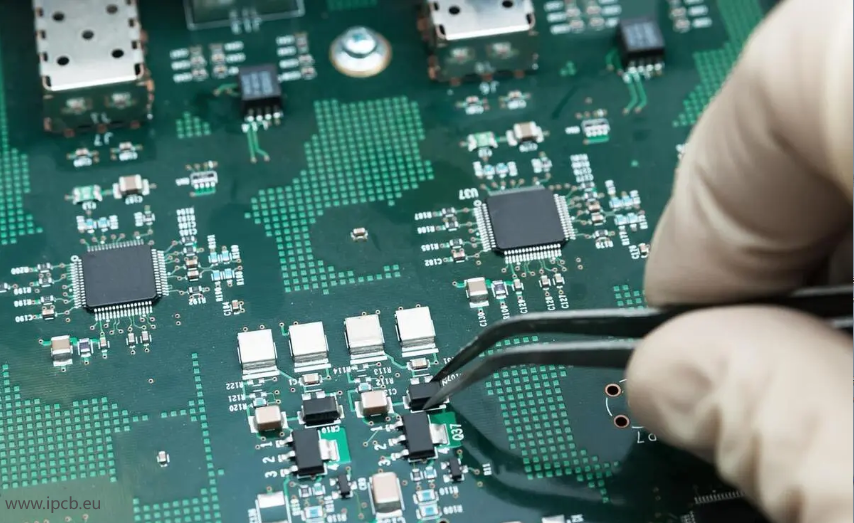

(1) Improve integration and performance: Use micro-hole technology and blind and buried hole technology to achieve higher density wiring and inter-layer interconnection; improve the electrical performance and reliability of circuit boards through material selection and optimization.

(2) Quality control and reliability assurance: Strengthen the quality monitoring of fine lines and hole walls to ensure the quality and performance of circuit boards; conduct material reliability testing and evaluation, as well as aging and life prediction technology to ensure that circuit boards can provide stable performance in various environments.

(3) Production process optimization and improvement: Introduce automation and intelligent technology applications to improve production efficiency and product quality; optimize production processes and management innovation to reduce production costs and improve production efficiency.

5.Technical Challenges and Countermeasures

In the process of HDI circuit board manufacturing,manufacturers face many technical difficulties,such as high-precision processing technology challenges,material performance stability issues,and the balance between production costs and efficiency.

To solve these problems, manufacturers can take the following countermeasures:

(1) Research and develop new processing technologies and equipment: improve processing accuracy and efficiency and reduce production costs through technological innovation.

(2) Optimize material selection and supply chain management: select materials with stable performance and reasonable cost, and strengthen supply chain management to ensure the stability and reliability of material supply.

(3) Ways to improve production efficiency and reduce costs: improve production efficiency and reduce costs by optimizing production processes, improving equipment utilization and reducing scrap rates.

6.Outlook on Industry Application Prospects

With the rapid development of 5G communications, the Internet of things, smart homes, and automotive electronics, the application prospects of HDI circuit boards are very broad. At the same time, with the application of material innovation and new processes, intelligent technology and digital technology, the technology of HDI circuit boards will continue to upgrade and improve, providing strong support for the innovation and development of electronic products.

Application field expansion: 5G communication field, Internet of Things and smart home field, automotive electronics field

Technology development trend forecast: material innovation and new process development trend, intelligent and digital technology application trend

Share HDI circuit boards have become an indispensable part of modern electronic products with their high density, high performance and small size. With the advancement of technology, HDI circuit boards will continue to promote the development of electronic equipment and provide stronger support for various application fields.