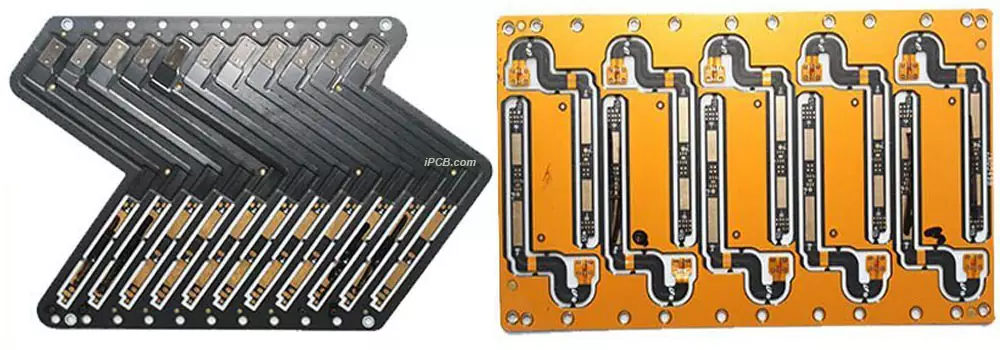

Currently.there are four types of FPC flexible circuit boards: single-sided FPC.double-sided FPC.multi-layer FPC and rigid-flexible bonded board.

1.Single-sided flexible board is the lowest cost.when the electrical performance requirements are not high printed board. In the single-sided wiring.should be used when the single-sided flexible board. It has a layer of chemically etched conductive patterns.and the conductive pattern layer on the flexible insulating substrate is calendered copper foil. The insulating substrate can be polyimide.polyethylene terephthalate.aramide fibre ester and polyvinyl chloride.

2.Double-sided flexible boards have a conductive pattern etched on each side of the insulating substrate. Metallised holes connect the patterns on both sides of the insulating material to form a conductive path to satisfy the design and function of flexibility. The cover film protects the single and double-sided conductors and signals the placement of the components.

3.Multi-layer flexible board is 3 or more layers of single-sided or double-sided flexible circuit laminated together.through the drilling of solenoids.plating the formation of metallised holes in the different layers to form a conductive path. This eliminates the need for complicated soldering techniques. Multi-layer circuits offer significant functional differences in terms of higher reliability.better thermal conductivity and easier assembly performance. The interaction of assembly size.number of layers and flexibility should be taken into account when designing the layout.

4.The traditional rigid-flexible board is composed of rigid and flexible substrates selectively laminated together. The structure is tight.with metallised solitons to form conductive connections. If a printed board front and back are components.rigid-flexible board is a good choice. However.if all the components are on one side.it is more economical to use a double-sided flexible board with a layer of FR4 reinforcement laminated on the back side.

5.Rigid-flex PCBs for flexible circuits are multi-layer boards where the conductive layers are made of different metals. An 8-layer board uses FR-4 as the dielectric for the inner layer and polyimide as the dielectric for the outer layer.with leads coming out of the motherboard in three different directions.each made of a different metal. Each lead is made of a different metal. Conoco alloys.copper and gold are used as separate leads. This hybrid construction is the only viable solution for low-temperature situations where the relationship between electrical signal conversion and heat conversion and the electrical properties are more demanding.

The convenience and total cost of the inline design can be evaluated to achieve the best performance to price ratio.

FPC

Economy of FPC Flexible Circuit Boards

If the circuit design is relatively simple, the total area is small, and the space is suitable, most of the traditional internal connectors are much cheaper. If the circuit is complex, handles many signals or has special electrical or mechanical performance requirements, a flexible circuit is a better design choice. When the size and performance of the application exceeds the capabilities of a rigid circuit, flexible assembly piping is the most economical. Flexible circuits with 12-mil pads with 5-mil via holes and 3-mil traces and spacing can be fabricated on a single sheet of film. In this case, it is more reliable to mount wafers directly on the film. This is because they do not contain flame retardants, which can be a source of ionic diamond contamination. These films may be protective and cure at higher temperatures, resulting in higher glass transition temperatures. The cost savings of flexible data over rigid data is due to the elimination of the need to connect to an external plug-in.

The high cost of raw materials is the main reason for the high price of flexible circuits.Raw material prices vary widely, with the lowest-cost polyester flexible circuits costing 1.5 times as much as rigid circuits, and high-performance polyimide flexible circuits costing four times as much or more. At the same time, the flexibility of the data makes it difficult to automate the manufacturing process, resulting in lower yields, and it is susceptible to defects in the final assembly process, including stripping of flexible attach, and wire breakage. These defects include stripping of flexible attachments and wire breakage, which are more likely to occur when the design is unsuitable for the application. In the case of high stresses caused by bending or moulding, it is often necessary to select reinforcing or strengthening materials. Despite the high cost of raw materials and the hassle of manufacturing, folding, bending, and multi-layer board features reduce the overall component size and therefore the amount of data used, resulting in a lower total assembly cost.

The flexible circuit industry is in the midst of a small but rapid growth. The polymer thick film process is a highly efficient, low-cost production process. The process selectively screen prints conductive polymer inks onto inexpensive flexible substrates. A representative flexible substrate is PET. Polymer thick film conductors include screen-printed metal fillers or toner fillers. The polymer thick film method is inherently clean, uses lead-free SMT adhesives, and does not require etching. Because of its additive process and low substrate cost, polymer thick film circuits are 1/10th the price of copper polyimide film circuits and 1/2 to 1/3 the price of rigid circuit boards. Polymer thick film is particularly well suited for device consoles. In mobile phones and other portable products, polymer thick film is suitable for converting components, switches and lighting on printed circuit boards into polymer thick film circuits. It saves money and reduces energy consumption.

Generally speaking, flexible circuits are more expensive and costly than rigid circuits.When flexible boards are manufactured, in many cases they have to face the fact that many parameters are out of tolerance. The difficulty in manufacturing flexible circuits lies in the flexibility of the material.

Cost of FPC Flexible Circuit Boards

In spite of the above mentioned cost aspects, the price of flexible assemblies is decreasing and becoming close to that of traditional rigid circuits. The main reason for this is the introduction of newer data, improved manufacturing processes and changes in construction. Today's structures allow for a more thermally stable product with few data mismatches. Some of the newer materials allow for thinner copper layers to produce more precise wires, making the components lighter and more suitable for fitting into smaller spaces. In the past, copper foils were bonded to adhesive-coated dielectrics using a rolling process, but today it is possible to create copper foils directly on the dielectric without the use of adhesives. These technologies allow for copper layers that are several microns thick, resulting in precision wires that are 2 mils or even narrower in width. Flexible circuits are flame retardant when certain adhesives are removed. This accelerates the uL certification process and further reduces costs. FPC solder masks and other surface coatings further reduce the cost of flexible assemblies.

In the coming years, smaller, more complex and costly FPC will require new and innovative methods of assembly, as well as the addition of new hybrid flexible circuits. The challenge for the FPC industry is to leverage its technological strengths to keep pace with computer, remote communication, consumer needs and active markets. In addition, FPC flexible circuit boards will play an important role in the move towards lead-free.