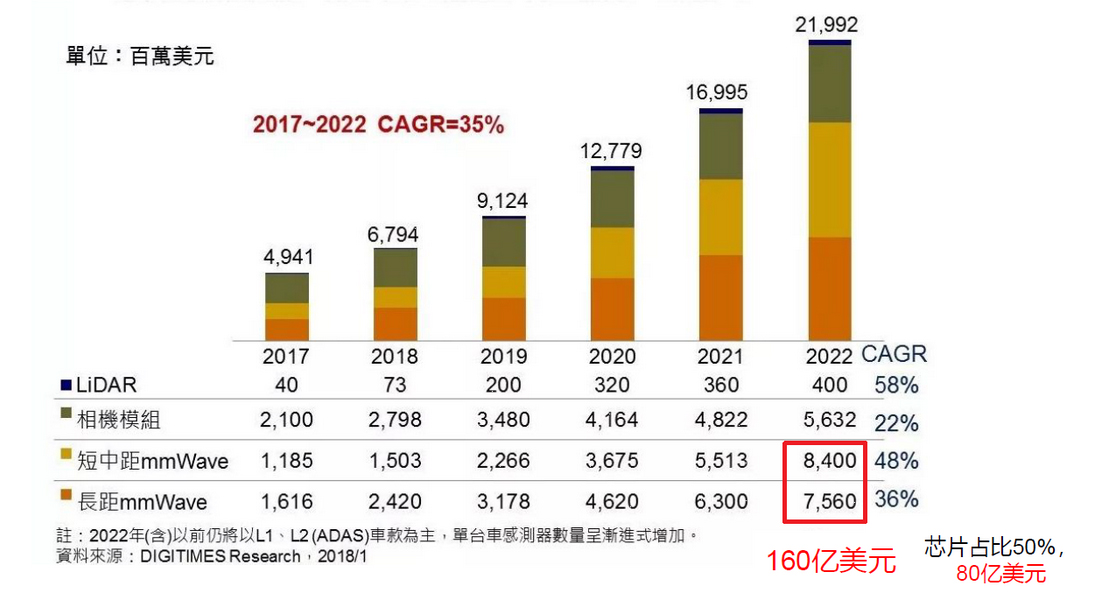

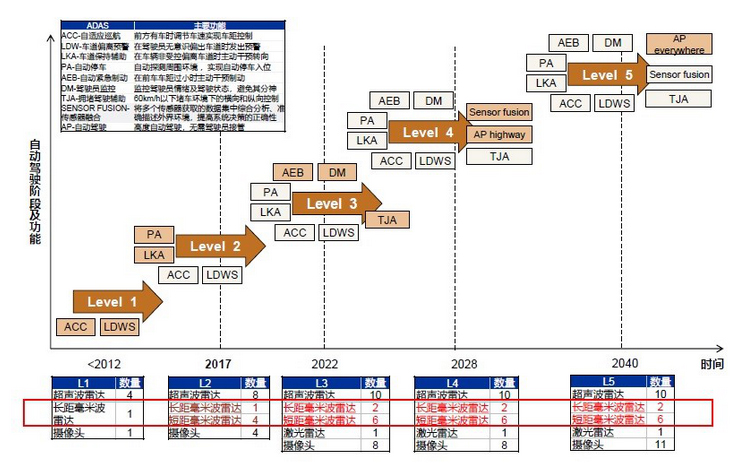

According to the research organisation's forecast, from 2017 to 2022, the automotive millimetre wave radar PCB circuit board market will reach a CAGR of 35%, and in 2022, the world's automotive millimetre wave radar market size will be about US $16 billion in total, with wafers amounting to about US $8 billion. Therein, the short- and medium-range millimetre wave radar PCB circuit board scale is 8.4 billion U.S. dollars, with a CAGR of 48 percent; the long-range millimetre wave radar circuit board market value is 7.56 billion U.S. dollars, with a CAGR of 36 percent.

As the CEO of the first company to launch a CMOS-77GHz millimetre wave radar circuit board transceiver chip for transport vehicles, Chen Jiashu, CEO of Gatland Microelectronics, told International Electronic Commodity Situation that in recent years, there have been many companies doing millimetre wave radar circuit board solutions in China, but most of them have been flashed in the form of boards, and the enterprises that are really able to do CMOS mass-production chips and front-loading are only Gatland's one company. Gatland is the only one.

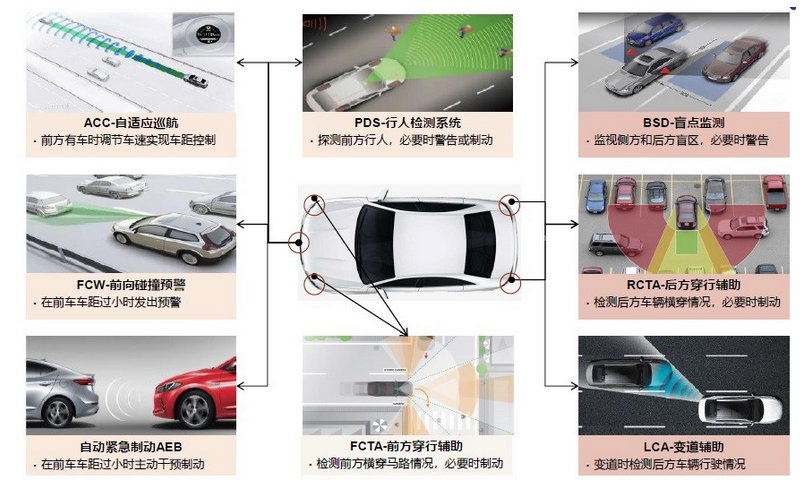

The listed model he mentioned is an SUV model from a domestic OEM, which supports the BSD rear retina that cannot receive light stimulation point vehicle recognition warning system and FCW front radar circuit board monitoring and detection anti-collision system. This means that for the first time since November 2018, a 77GHz CMOS millimetre wave radar PCB has been fitted to a 120,000-priced vehicle.

Low cost, high integration is the CMOS process advantages of the existence of the place, but more often than not it has not been used to make 77GHz millimetre-wave radar PCB. the end of the reason is in the CMOS process of the crystalline tube speed has not been able to reach the radar office frequency, only when the CMOS process into the 40 nm old in 2010 to have the possibility of successful realisation.

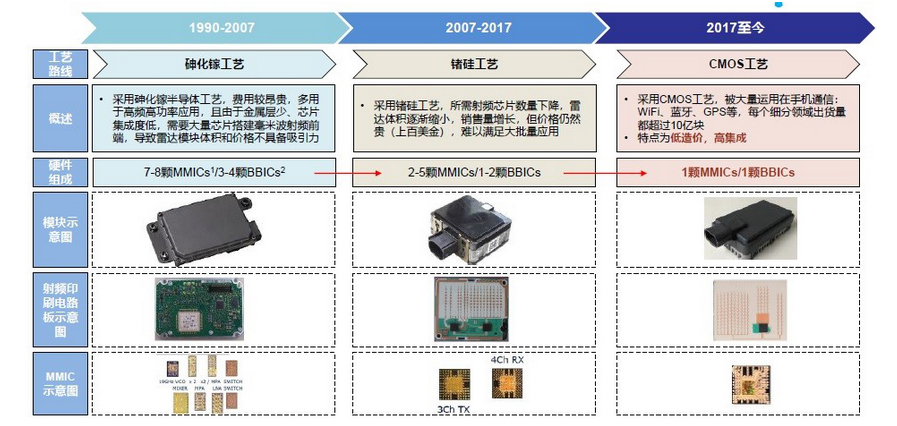

In the 1990s-2007,millimetre wave radar pcb mainly used GaAs process, which was extremely expensive, mostly used for high frequency and high power applications, and due to fewer metal layers, low chip integration, the number of chips required to build millimetre wave RF front-end (7-8 MMICs/3-4 BBICs) was high, resulting in the size of the radar boards and the price point did not have the attractive force; in 2007-2017, gaAs process was the only process that could successfully realise this. In 2007-2017, the SiGe process has gradually matured, the number of RF chips required for the system has been greatly reduced (2-5 MMICs/1-2 BBICs), and the size of the radar has gradually changed from large to small, which has pushed forward the application of millimetre-wave radar in the ADAS system of vehicles. However, the price is still on the high side (hundreds of US dollars), in addition to high-end automotive systems, the SiGe process of 77GHz products is still difficult to satisfy a large number of applications; and from 2017 until now, the low cost, highly integrated CMOS process has reduced the number of radar RF chips to 1 MMIC / 1 BBIC.

‘Although there are a lot of foreign semiconductor giants working hard to develop millimetre wave radar chips, frankly speaking, they do not have a dominant position in the advanced CMOS millimetre wave radar chips.’ Chen said that millimetre-wave radar is a recently emerging field, and there is no one company with deep experience that is difficult to surpass. Gatland was established in 2014, but its central development team in the field of millimetre wave technology and industrialisation experience has been accumulated for more than 10 years, the enterprise so far in the world has been with more than 90 customers to open up cooperation, in the transport, transportation, security, safety inspection imaging and other fields to obtain a number of breakthroughs, the real power does not lose no matter what an international enterprise.

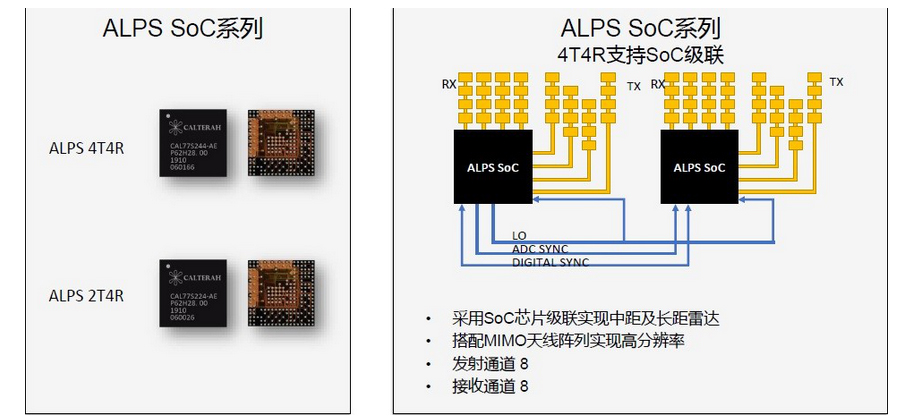

Following the announcement of Yosemite, the 1st generation of 77GHz CMOS millimetre wave radar RF SoC in 17 years, Gatland Microelectronics, after more than 2 years of meticulous grinding, has once again launched the ALPS series of millimetre wave radar system-on-chip with higher integration a few days ago.The new product integrates a high-speed ADC, a complete radar signal disposal baseband and a high-performance CPU core, and will be available for engineering samples in the second quarter of this year, and will be successfully realised in mass production in 2019.

Although Chen feels that a two-year development cycle is already quite fast in the industry,he still expects that corporate development teams will be able to compress the time to market to a year and a half or even less in the future.Due to safety concerns,OEMs final road test,verification time is difficult to compress, can reduce only the development cycle,when the user in the use of ALPS series after this, it does not have to consume in the algorithm and the underlying research and development of the money more mental energy, you can put more time into the application of the R & D,and vehicle manufacturers to connect with the aspects of the preset cycle is therefore detrimental.

The significant improvement of RF and digital processing performance are the two highlights of this new product.In the RF area,the ALPS chip integrates digital circuits such as four or two transmitter channels, four receiver channels,a highly configurable waveform generator, an analogue-to-digital converter with a sampling rate of up to 50Msps,and a signal processing system. The functionally secure ARC EM6 CPU core provides users with 300MHz of numerical processing experience to successfully implement tracking algorithms, lead application algorithms,and choke software.

Alps saw fit to use a ‘V’ shaped R&D process,with more than 190 functional safety monitoring boards participating in the pre-designed programme, involving over a hundred million crystalline tubes tested and analysed, up to 1,000 loss of validity standardised samples profiled, and loss of validity re-inspection testing integrated with the test and validation loss of validity boards, to ultimately achieve an ASIL-B functional safety rating. In addition to the standard products,the company is also launching a series of new products, which will ultimately reach the ASIL-B functional safety level.

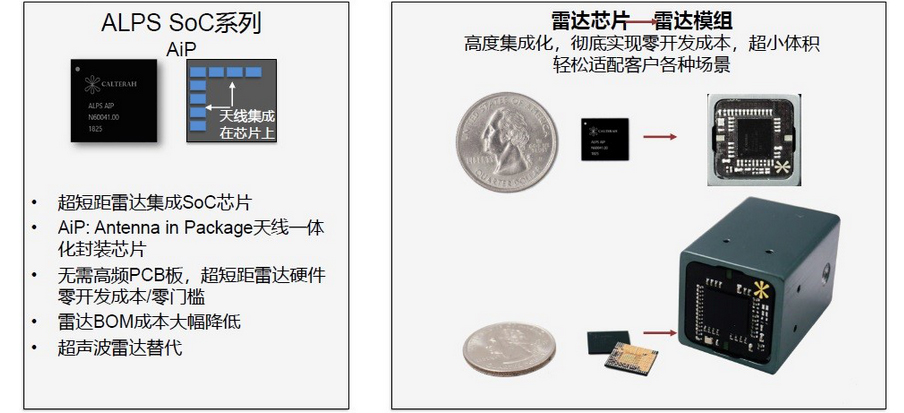

In addition to standard products, the simultaneous launch also covers the Alps AiP (antenna in package), which integrates the receiving antenna unit into the chip package layer, the Alps 2T4R, which has a better price-performance ratio, and the 60GHz SoC products,which continue to be able to provide customers with all-around and complete solutions from long-range, medium-range to short-range, and ultrashort-range in the state of a pro-platform, which is very helpful to reduce the difficulty of radar research and development.This reduces the difficulty and cost of radar development.

In order to promote the Alps series products and customer R&D, Gatland Microelectronics also launched the RDP radar R&D platform and GUI user interface and other tools, as well as a compatible and complete software to integrate the R&D background and tool chain. This series of tools will make the radar chip easier to use and greatly reduce the time-to-market for customers.

In addition, in order to meet the challenges of the new context of traditional semiconductor marketing standards,Gartland Microelectronics has not only updated its official website, WeChat public platform and other official channels, but also launched the Taobao official shop to simplify the process of small-quantity purchases for customers.

Gatland microelectronics business operations vice president Lu Yuzhao interpretation of this,Taobao shop will not be implemented in large quantities of goods, just because customers expect to get the product faster, and the traditional form of docking for small orders is too complicated,so expect to show Taobao shop's convenience of the unique place. Of course, Internet marketing itself has a certain degree of wide distribution, which is also a good thing for businesses. In the future, online forums and service platforms will be upgraded to provide better support and service to customers.

Chen Jiashu said, 77GHz millimetre wave radar chip is not easy to solve the preset places, one is from the technology itself, such as how to successfully realise a millimetre wave band on the standard digital CMOS process, including phase-locked ring, transmitter, transceiver, mixer in the millimetre wave band complete circuit system, and then to make the system can be operated securely in the temperature range of -40 to 120, the degree of difficulty is very great.

It is a well-known fact that the CMOS process is the most widely used semiconductor process, but it is not designed to successfully implement high-frequency circuits and applications, and its greatest strength lies in its ability to successfully achieve digital integration. Because of this, the development of the person in charge of both the need to fully understand the special nature of the CMOS process semiconductor, but also the need to use a large number of digital circuits to try to take care of or enhance the simulation of some of the circuit shortcomings and shortcomings, so as to complete the set of system performance is better.

Secondly, the new ALPS series has not only a RF front-end, but also a radar signal processing engine, which is another challenge to successfully realise a high-performance, low-power radar processing baseband. The reason why Gatland's default role was not to use standard DSP components was that they found it appropriate to use hardware acceleration in the form of ASICs to successfully achieve both higher performance and lower power consumption, but this would have involved a significant amount of algorithmic R&D work. In addition, the vehicle radar application scene and the traditional military airborne radar is very different, how to integrate the entire child radar signal processing engine into a single chip, and RF front-end successfully achieve seamless connection, synchronous office, is also a major not easy to solve the problem.

We feel that the experience of millimetre-wave radar is far from being utilised at this stage. Increasing the number of probing observation purposes, providing a higher angular defence rate, and becoming smaller in scale, and further developing the radar algorithms and RF chip architecture are the future directions of millimetre-wave radar chip development, and the direction of the company's endeavour as far as possible. However, the speed of iterative computing in transport products is far less than that of consumer products, so we will listen carefully to the needs of the market and customers before finalising the specifications for the next generation of products.

There is no ‘omnipotent sensor’ because the millimetre wave radar has the experience of speed measurement, distance measurement, angle measurement, all day and after office, so the industry has a great need for this kind of sensor, and it is also the main sensor of the current L2 to L3 level of intelligent operation. Until now, L2 class car models basically use 3 (1 long distance + 2 short distance), to about 2022, the L3 stage car models will increase to 8 (2 long distance + 6 short distance), to about 2040, L5 class car models will also be considered appropriate and use the same equipment layout.

Whilst the number of radars will increase the number, precision and range of probing observations, whether the cost, size and power consumption can be accepted by vehicle manufacturers will be a major challenge. For IC manufacturers, the aim is to reduce the cost of millimetre wave radar systems to a level where more than 10 radars can be mounted on a single vehicle.

Alongside millimetre-wave radar in the field of semi-autonomous manoeuvring, there is also laser radar (Lidar). The biggest bottleneck of Lidar is still the high cost, almost the cost of a whole car can only make it more used in unmanned manoeuvring test vehicles, 5 years or even a longer period of time are more difficult to achieve successful assembly in passenger cars. This invariably gives millimetre wave radar chip manufacturers the opportunity, how to supply high integration, low cost, easy to use CMOS chip, so that more Tier1 and OEM manufacturers as much as possible to speed up the introduction of millimetre wave radar sensors, the success of the high, medium and low-end models of the full coverage of the vehicle millimetre wave radar PCB circuit board manufacturers need to think deeply about the problem.

From a long-term perspective, visual sensory, millimetre wave radar, laser radar, these individual sensors will co-exist, show their own work speciality, to remedy the shortcomings of the other side, because the vehicle is also the need for redundancy preset. Visual sensory sensor's strength lies in the information volume is vast, can identify lane lines, road signs, signs, but no rut to do very accurate survey distance, and by the light, weather influence is relatively large; Based on the electromagnetic wave principle of millimetre wave radar can be all day and after the office, not subject to the influence of external conditions, and can be very accurate survey. But in the AEB, ACC system generally need two kinds of sensors to implement the synthesis of one, even if there is a strong enough performance, but also need an additional one for the value of the mutual investigation.