Glass substrate is a kind of thin glass sheet composed of silicate complex salt and so on, which has physicochemical characteristics such as high flatness, good thermal stability, low coefficient of thermal expansion, low dielectric loss, and good chemical stability. Compared with silicon as well as organic materials, glass-based materials are in an advantageous position in terms of electrical properties, physical properties, chemical properties, thermal properties and mechanical properties are also better than organic materials, can be applied to a variety of high-demand electronic packaging field, and is now increasingly used in semiconductor chips and high-definition display and other fields.

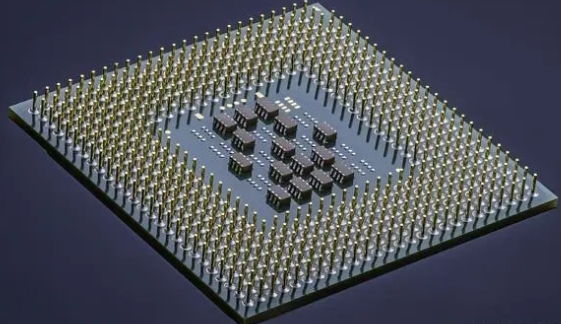

glass substrate

According to chip company Intel's research, due to the existence of organic materials, power consumption, shrinkage and warping and other limitations, the semiconductor industry in the use of organic materials in the silicon package may reach the limit of the ability to shrink the transistor, glass substrate can be done in line width, line spacing, bump size, etc. to be more fine, can effectively improve the interconnection density and other aspects of performance, the application of glass substrate is expected to help the semiconductor industry in the The application of glass substrates is expected to help the semiconductor industry to maintain Moore's law after 2030.

CICC research report that, with the gradual increase in demand for AI computing power, hardware circuits are highly complex, whether it is the original widely used PCB organic substrate, or to improve the packaging density of TSV technology will become a constraint on the production of high-performance computing power chips, such as AI chips, the short board in the foreseeable time. In contrast, glass substrates have become the focus of research on new advanced packaging technology substrates by virtue of their natural electrical properties, excellent mechanical properties, good thermal conductivity and low coefficient of thermal expansion, and the introduction of glass substrates in the field of encapsulation is an important technological innovation.

Based on the glass-based huge industrial application prospects, including Intel, AMD, Samsung, SK Group and many other chip heads have launched a glass-based product development program. Intel will mass produce glass substrate in 2030, and has invested 1 billion dollars in Arizona plant to establish a glass substrate R & D line and supply chain; AMD is a number of major semiconductor substrate enterprises, including the Japanese enterprise new photoelectricity, Taiwan enterprises Xinxing Electronics, Korean enterprises Samsung Electro-Mechanics and Austrian Otis, including glass substrate samples for the performance evaluation test, the company is expected to be as early as in 2025 - 2026, the introduction of the product in the product. The company expects the earliest in 2025-2026 products into the glass substrate; Samsung is expected to build glass substrate prototype production line in 2024, 2026 into mass production.

Prismark expects that with the entry of major chip giants, glass substrate is expected to accelerate the replacement of silicon substrate, glass substrate penetration is expected to reach 30% within three years, and penetration will reach more than 50% within five years.

Glass substrate in the field of high-definition display applications are promising. In addition to the chip field, high-definition display is another important application of glass substrates. Glass substrate high transparency and optical uniformity to ensure good optical performance, excellent flatness to ensure the quality of the display, mechanical strength and chemical resistance to enable it to cope with a variety of environments, while thermal stability and low coefficient of thermal expansion ensures that the product in the operation of the high load stability. The self-luminous nature of glass substrates also makes them particularly important in new display fields such as Micro LEDs.

Research predicts that by 2026, global shipments of MiniLED backlight products will increase to 49.18 million units, with a 2022-2026 CAGR of about 30%; GGII predicts that the global MicroLED market is expected to exceed $10 billion in 2027, with a 5-year CAGR of 151%. With Mini/MicroLED penetration rate climbing, it is expected to drive the demand for glass substrate high increase.