Now more and more customers in the PCBA manufacturing time, are choosing one-stop service, including PCB boards, PCBA playing pieces as well as programming test all to PCB and PCBA one-stop manufacturers, today we give you a talk about the PCBA is how to burn the programme?

What is PCBA programme programming?

To allow the PCBA board to achieve the specified function, it is necessary to let the chip on the PCBA run up, the written programme is correctly programmed into the chip, you can let the chip run up. PCBA programme programming, i.e. the process of moving the programme into the chip's internal storage space, is generally divided into offline programming and online programming.

Nowadays, the packaging of widely used Emmc and other chips is developing in the direction of small size and planarisation such as BGA, QFN, etc., and the price of adapters for these packages is not low.

PCBA Offline Programming

Offline programming is through the adapter and different packages of the chip connection, the chip and the adapter with the use of the programme can be programmed. The nature of the adapter is similar to a precision fixture, and different packages of chips need to be programmed with different adapters. If an error occurs during production testing and production backtracking is needed to correct the error, the chip needs to be removed from the adapter and programmed again according to the prescribed process, which is costly and requires a lot of manpower and resources. In PCBA production, there will be some unexpected conditions, such as circuit board temperature resistance height is not enough, when removing the chip will cause deformation of the chip, invariably adding the risk of scrapping.

PCBA Programming

PCBA In-Line Programming

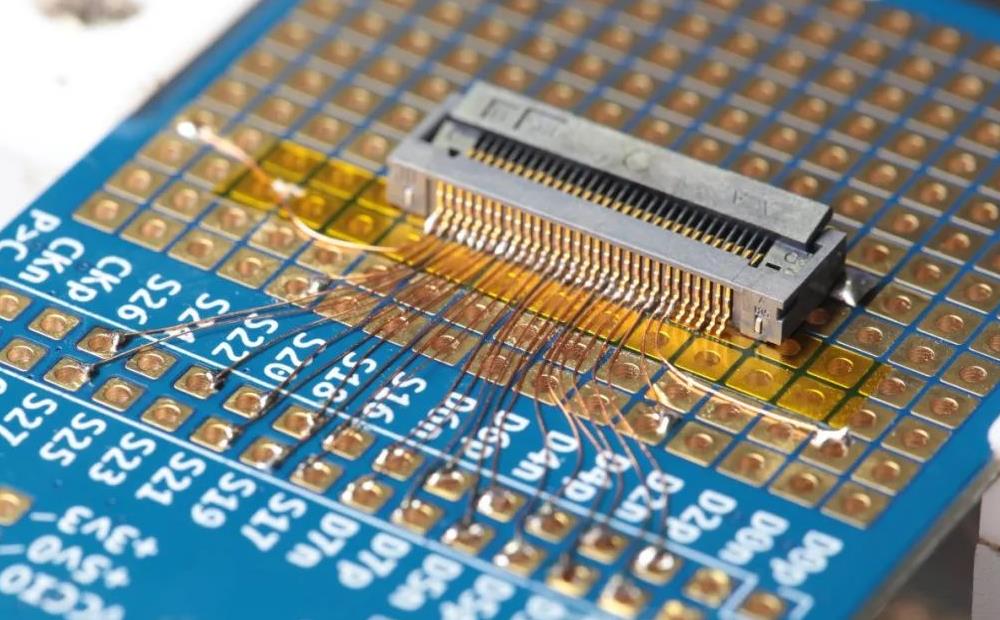

In-line programming uses the standard communication buses of the chip, such as USB, SWD, JTAG, UART, etc. The interfaces are generally fixed, and very few pins need to be connected when programming. Since the interface communication rate is not high, programming can be done with normal wires without high consumption.

In-line programming is through the wire connection to carry out travelling type programming, if the production test time found that the error, you can immediately back to the wrong PCBA, re-programming can be, without the need to disassemble the chip. This not only saves production costs, but also increases the efficiency of programming.

More importantly, the production line is now also developing towards automation, more and more manufacturers will ICT, FCT and other functional test machines added to the production line, the use of automated fixtures with online programming production can be eliminated in the programming stage of the manual operation, paste the board directly after the programming, and then the PCBA will be sent to the tester to test, the entire production process is fully automated, which can greatly improve the production efficiency.

In PCBA processing, the advantages of online programming is very obvious. But you can also be based on the actual needs to decide whether to offline programming or online programming.

PCBA programming programme process capabilities

1.Open circuit (open), short circuit (short), detection of faulty parts, missing parts,monument,bridge,reverse polarity.

2.Can measure resistance (resister), capacitance (capacitor), inductance (Inductor),transistors,diodes (diode),voltage stabilised diodes, triode measurement (triode) optical coupler,relays,field effect transistor test (FET), IC, connectors and other parts.

3.Through TestJet can not need to pinpoint can measure row PIN connector or pin outside the IC parts open and short circuit.

4.DC/AC voltage measurement and frequency measurement.

5.Electrical function test. Can perform low-level programmes to do self-test.

6.Can use [Boundary-scan/JTAG] to test the function of active parts.

7.Can automatically download software or operating system into the memory of the circuit board.

PCBA Programming Fixture

PCBA programmeburning quality control

1.Quality Control Department organise the unqualified or non-conforming responsible departments or bad found departments,etc.on the fact that the organisation is not assessed, and set up a problem-solving team.

2.For potential defects or non-conformities through the use of tests, analogies, data analysis, QC techniques and other tools to analyse and carry out appropriate error-proofing design and quality control, and put forward preventive action plans.

3.For defective or non-conforming items that have occurred, the problem-solving team to re-examine and approve amendments to the relevant technology, quality standards or to improve the technology or design standards, etc., to confirm the quality system related to all products or processes whether there are similar problems and to carry out a comprehensive preventive and proposed solutions.

In the PCBA programming programme, should choose the appropriate programming programme and quality control.