How to distinguish between FPC connector and FPC? Here is a brief introduction:

FFC connectors and FPCs are often confused in the connector world. Although both are flexible cable connectors, there are certain differences between FFC connectors and FPC connectors. Flexible flat cable connectors and FPCs are flexible printed circuits. In terms of manufacturing, the way they are wired is different.

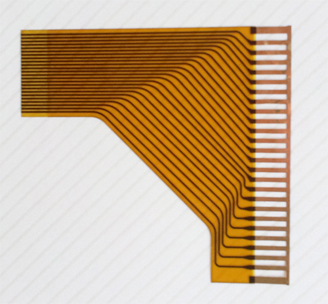

FPC is FCCL (Flexible Copper Clad Laminate) chemically etched and processed into flexible circuit boards with different single-sided, double-sided and multi-layer structures, while FFC is two layers of insulating foils sandwiched between flat copper foils, and the finished product is simpler and thicker. Strictly speaking, FFC is much cheaper and more companies prefer to use FFC related designs when considering production costs.

After the production of FPC flexible circuit board products, circuit board factories often need to adopt the correct method to carry out quality inspection to ensure the quality of the circuit board. What are the methods to detect the quality of FPC flexible circuit boards? Here is a brief introduction:

1.Copper foil adhesion refers to the printed circuit and pad adhesion on the substrate. Adhesion is small, printed wires and pads can be easily peeled off from the substrate.

Circuit board factory to check the adhesion of copper foil available tape, tape through the wires to be tested, remove air bubbles, and then quickly pull off the tape with a 90 ° target of the printed circuit board, if the wires are intact, note that the printed circuit board copper foil adhesion after.

2.Circuit board factory quality inspection, including surface brightness, screen printing as clear, whether the solder plate is rounded, whether the centre of the pad is welded hollow, with a photographic reproduction of the printed circuit board has been processed to do the laminating, to determine whether the printed circuit board edge dimensions, width and the appearance of the lead is in the requirements of the range.

3.The solderability of the pad is an important indicator of the printed circuit board. Focus on measuring the wetting of the pads on the printed circuit board can be divided into wet, semi-wet and non-wet three indicators.

4.Electrical function check mainly includes FPC flexible board insulation and connectivity, can be measured through the light board tester.

Insulation check focuses on the measurement of insulation resistance. Circuit board manufacturers can choose two or more wires close to each other, the first measurement of insulation resistance, humidification and heating for a certain period of time, back to room temperature and then measured.