Microelectronic packaging has gone through the dual in-line package (DIP) package, small outline (SOP) package, four-edge lead flat (QPF) package, ball-grid package (BGA) and chip size (CSP) package, etc., the size is getting smaller and smaller, the electronic components from the discrete components, integrated pathway, chip on chip (SOC), stagnation of more simple fragmentation level packaging pathway (SIP). SIP using micro-disassembly and interconnection technology, can be integrated into a family of integrated paths such as CMOS path, GaAs path, SiGe path or perhaps optoelectronic devices, MEMS devices, and a variety of passive components such as resistors, reservoirs, inductors, filters, mice, etc. integrated into a package, and therefore can be ineffective and the most cost-effective use of the various families of technology combined to complete the performance of the parts of the fragmentation.

LTCC technology is in recent years the rise of an eye-catching integrated component technology, because LTCC data excellent electronic, mechanical and thermal characteristics, widely used in PCB substrates, packaging and microwave components and other areas, is the main path to complete the fragmentation of the packaging. We have developed a product that integrates no different functions into a single device, and it is smoothly used in wireless wide area network, sky digital broadcasting, global positioning chip absorber, microwave chip, and other power supply sub-functions modules, digital path substrates, and other areas.

Based on the advantages and characteristics of LTCC technology to complete the SIP, the RF former SIP developed by Tandem gives an example of use.

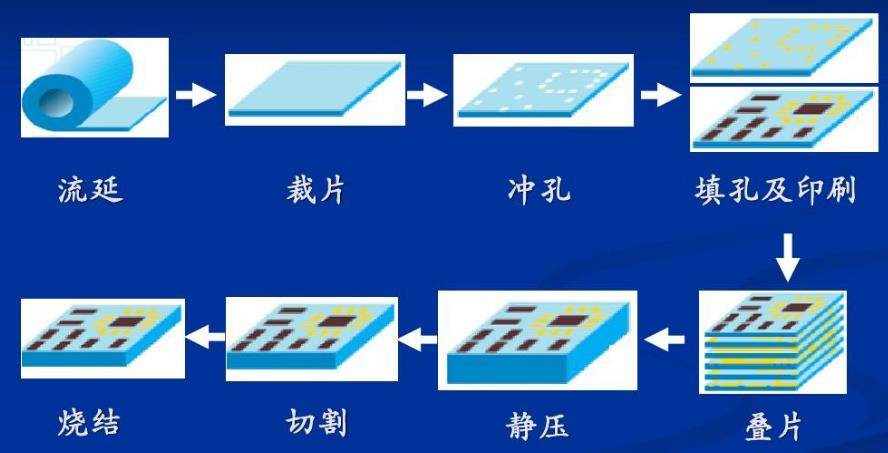

LTCC process

1.The disadvantageous characteristics of LTCC technology to complete SIP.

LTCC technology is a high-temperature sintered ceramic powder brewed into a thin, thick and dense raw ceramic tape, raw ceramic tape on the application of punching or laser drilling, microporous grouting, fine superconductor paste printing and other crafts to create the required pathway pattern, and passive components and performance pathways can be embedded into the multi-layer ceramic substrate, and then laminated together, sintered at 850 ~ 900 ℃, brewing three-dimensional time of the High-density pathways. LTCC-based SIPs have significant advantages over conservative SIPs, with the greatest strengths being excellent high-speed, microwave functionality and extremely high integration. The details are shown in the following ranges:

(1) IXCC technology adopts multi-layer interconnection technology can improve the integration degree, IBM completed the goods have reached more than 100 layers, NTT future network drilling research for LTCC module way to produce SIP goods for sending millimetre band 60GHz spectrum, the size of the 12 mm × 12 mm × 1.2 mm, 18 layers of wiring layer consists of 0.1 mm × 6 layers and 0.05 mm × 12 layers, integrated with the antipodal band. The 18-layer wiring layer consists of 0.1 mm×6 layers and 0.05 mm×12 layers, and integrates components such as ground with reflector, power reducer, bandpass filter and voltage master oscillator, etc. The LTCC data thickness has been serialised in front of the eyes, and the normal single-layer thickness is 10~100 μm.

(2) LTCC can produce a variety of structural cavities, and embedded meta-machine components, passive performance components, through the reduction of the length of the coupling chip superconductor and the number of contacts, can be integrated into a variety of components, easy to complete the multi-functionality and improve the disassembly density. The improved wiring density and component integration reduces the number of SIP core pathway components, simplifies the core pathway design in connection with SIP, and raises the difficulty and profitability of pathway disassembly.

(3) according to the ingredients do not have the same, LTCC data dielectric constant can be in a wide range of changes, according to the use of the request for sensitive configuration without the same data characteristics of the substrate, to improve the design of the sensitivity. For example, a high-function SIP can contain microwave routes, high-speed numeric paths, broadcasting section of the analogue signal, etc., can adopt the absolute dielectric constant of 3.8 substrate to design high-speed numeric paths; absolute dielectric constant of 6 ~ 80 substrate to achieve high-frequency microwave route design; dielectric constant of the substrate design of the various groups of passive components, and initially they are stacked together with the burning firm to achieve the entire SIP design. In addition, because of the low amount of co-firing, can adopt Au, Ag, cu and other high conductivity data as the interconnect data, there is a smaller interconnect superconductor consumption, especially suitable for high-frequency, high-speed pathway use.

(4) SIP based on LTCC technology has excellent heat dissipation. Nowadays, the performance of electronic goods is more and more, in the infinite time to integrate a small number of electronic components, heat dissipation function is the response to the function of the fragmentation and reliability of the main elements. LTCC data exists in the excellent thermal conductivity, according to the study of the thermal conductivity of the inorganic data is 20 times more than the drilling, and also because of LTCC coupling holes are adopted to fill the holes in the form of the characteristics of a better conductivity can be accomplished.

(5) LTCC technology based on the SIP and semi-superconductor devices have excellent thermal matching function. LTCC TCE (thermal coefficient of contraction) and Si, GaAs, InP is on the verge of being able to indirectly on the substrate to stop wafer disassembly, which is about the adoption of SIP without the same wafer data has a non-normal significance.

High-frequency, high-speed, high-function, high-reliability is the number of words 3C goods stagnation must trend. It is estimated that by 2010 SIP's wiring density can reach 6,000 cm/cm2, heat density up to 100 W/cm2, component density up to 5,000/cm2, I/O density up to 3,000/cm2. Based on LTCC technology SIP in the Department of highly integrated, high-power use, in the data, technology and other areas will enter a new stage of stagnation in the future use of more and more dominant in the number of words 3C goods stagnation. In the future, it will occupy a more and more important position in the use.

2.LTCC technology use example

Based on the LTCC technology,Bai developed a one-time RF absorption former SIP,which was realised by the IXCC process of XIII Institute. The minimum line width and line distance are 50 μm; the hole diameter is 170 μm; the same through-hole can be through-hole at a maximum of 15 layers;the reservoir value range is 1.0-100 pF;the inductance value range is 1.0-40 nH; the resistor paddle square resistance is 10 Ω / □, 100 Ω / □, and 1 kΩ / □, the amplitude of a minimum of 0.2 mm, the length of a minimum of 0.3 mm,the resistor mastering accuracy is external ± 20%,nominal The precision of resistance control is ±20% externally and ±5% nominally.

The RF absorber SIP is a 12-layer LTCC substrate with a substrate size of 39 mm × 20 mm × 1.2 mm.12 GaAs MMIC and CMOS mastering paths are externally mounted, as well as more than 30 SMD resistor, capacitor and inductor components, including LNAs, attenuators, microwave gates, integrated inductors,capacitors, resistors, and so on, with four RF ports and a good number of mastering and power supply terminals. Adopting a multi-channel plan, the switching between channel filter banks is done through two PIN single-knife multi-throw gates. The aperture size of the non-metallic fill holes for the transition between the microstrip line coupled to the PIN gates and the strip line filters has been optimised to minimise transition consumption. The filters are fully integrated into the LTCC substrate, and in order to ensure the isolation of the filters from each other, the strip line filters are adopted so that there is no isolation of the filters in the same layer, and the response to the rest of the path is minimised. In order to reduce the noise response of the rear stage, the front stage reducer adopts a high value-added LNA, which adopts the secondary conversion technology to convert the second midrange frequency to 100 MHz, and reduces the volume to 1/50th of the original one compared with the same product made by adopting the conservative mixed-path technology.