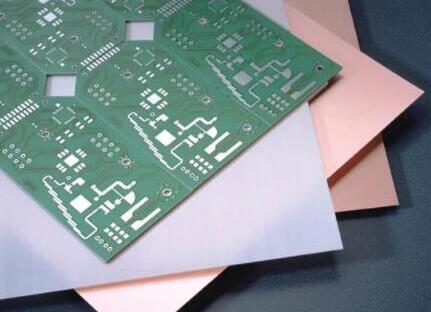

Multilayer PCB Materials for Millimeter Wave Applications

As more and more millimeter wave circuits adopt multilayer PCB boards, the demand for pcb materials is also increasing. These materials must not only meet the power and performance requirements of high frequency/high speed circuits, but also the mechanical requirements of multilayer circuits. This type of multilayer PCB board is usually composed of circuit laminates and bonding sheets (bonding materials) to laminate together. For higher frequency applications, such as Rogers' RO3003, the circuit board material achieves low loss circuit characteristics at millimeter wave frequencies.

This PTFE circuit laminate based on low Dk ceramic filler has a Z-axis (thickness direction) Dk of 3.00 and a Df of 0.0010 at 10GHz. Its thickness range is variant, from 0.005 inches (0.13 mm) to 0.060 inches (1.52 mm).

Multilayer PCB Board Materials

RO3003 laminate has been widely used in 77GHz single-layer circuit boards, with reliable dimensional stability and temperature characteristics. It also performs very reliably in multilayer PCB structures. The material has a thermal expansion coefficient (CTE) of about 17 ppm/°C in the X and Y axes, which is the same as copper, and can achieve high dimensional stability in multilayer PCB assemblies. When micropores need to be designed in the characteristic layer with a Z-axis CTE of 25 ppm/°C, stable and reliable plated through holes (PTHs) can be achieved. In addition, it has a low moisture absorption rate of 0.04%, making it suitable for different humidity working environments.

The smoothness of the copper foil surface of the circuit laminate is particularly important at higher frequencies, so Rogers has designed and developed RO3003G2 circuit board material. It is based on the original RO3003 laminate with optimized fillers to reduce the porosity of the dielectric and the surface roughness of the copper foil.

RO3003G2 and RO3003 have almost the same dielectric Dk and Df values, but RO3003G2 uses smoother copper foil, so it has lower loss at millimeter wave frequencies. At the same time, RO3003G2 inherits the good CTE performance of RO3003 laminate in the XY plane, and the optimized packaging system makes the Z-axis CTE value (18 ppm/°C) closer to copper, and has very reliable metallized via holes (PTH) performance. The material is available in thicknesses of 0.005 inches (0.13 mm) and 0.010 inches (0.25 mm).

When mechanical stability and thinner pcb materials need to be considered, such as in multilayer PCBs where size and weight must be minimized, CLTE-MW? circuit board materials can meet the performance requirements of the circuit. CLTE-MW? The material uses an open glass fiber structure and a low Dk ceramic filler system, which has excellent dimensional stability. Its thickness ranges from 0.003 inches (0.076 mm) to 0.010 inches (0.25 mm), which can meet the grounding spacing requirements of different signals, while minimizing the size and weight of multilayer PCB components. For different thicknesses, CLTE-MW The Dk value of the material on the Z-axis is in the range of 2.94 to 3.02 at 10GHz. It also has good CTE performance and PTH reliability, and its moisture absorption is also very low, only 0.03%, which can adapt to various challenging working environments.

The bonding material and semi-cured material's function is not only to fix the layers of the multilayer PCB circuit together, but they will also become part of the PCB. Therefore, it needs to be selected based on its electrical, mechanical and bonding performance. Take Rogers' 2929 bonding material as an example. It is compatible with both press and high pressure bonding methods when processing multilayer PCBs. 2929 bonding material is also available in different thicknesses. It has a Dk value of 2.94 on the Z-axis at 10 GHz and a low Df value of 0.003. Low Z-axis CTE ensures reliable PTH reliability and is compatible with PTFE PCB materials. Strong bonding of multilayer PCB boards.

Rogers' SpeedWave300P is a prepreg that is fully RoHS compliant and can be used as a semi-cured material for lead-free assembly throughout. It can be used to process FR-4 and PTFE-based circuit board materials (such as CLTE-MW laminates). This prepreg has a low Dk of 3.0 to 3.3 (depending on thickness) and a low Df value of 0.0019 to 0.0022, good flow and filling properties, low Z-axis CTE, and can achieve reliable PTHs. Especially in high-speed digital circuits, it can provide a variety of optical fiber openings and standard glass fabric configurations, as well as combinations of different resin contents to achieve the best bonding effect. With the increasing popularity of millimeter wave bandwidth, multilayer PCBs containing millimeter wave circuits will also become more and more common, with more and more layers and smaller sizes. Choosing the right circuit board material and prepreg will bring everything closer together.

iPCB is a professional high-precision PCB circuit board R&D and manufacturing manufacturer, with a production capacity of 4-46 layers of PCB boards, circuit boards, printed circuit boards, high-frequency boards, high-speed boards, HDI boards, PCB circuit boards, high-frequency and high-speed boards, IC packaging boards, transistor test boards, multilayer PCB boards, HDI circuit boards, mixed-pressure circuit boards, high-frequency circuit boards, and flexible-rigid combined boards.

iPCB has a strong technical team and advanced production equipment, and has passed the ISO9001:2015 quality management system certification, ISO14001:2015 environmental management system certification, and IATF16949:2016 automotive quality management system certification. The company's products are widely used in communications, computers, consumer electronics, industrial control, medical electronics, automotive electronics, and other fields.

iPCB has always been committed to providing customers with high-quality, high-reliability PCB circuit boards, and has won the trust and praise of many customers. The company will continue to uphold the spirit of innovation and pragmatism, and strive to become a leading enterprise in the PCB industry.