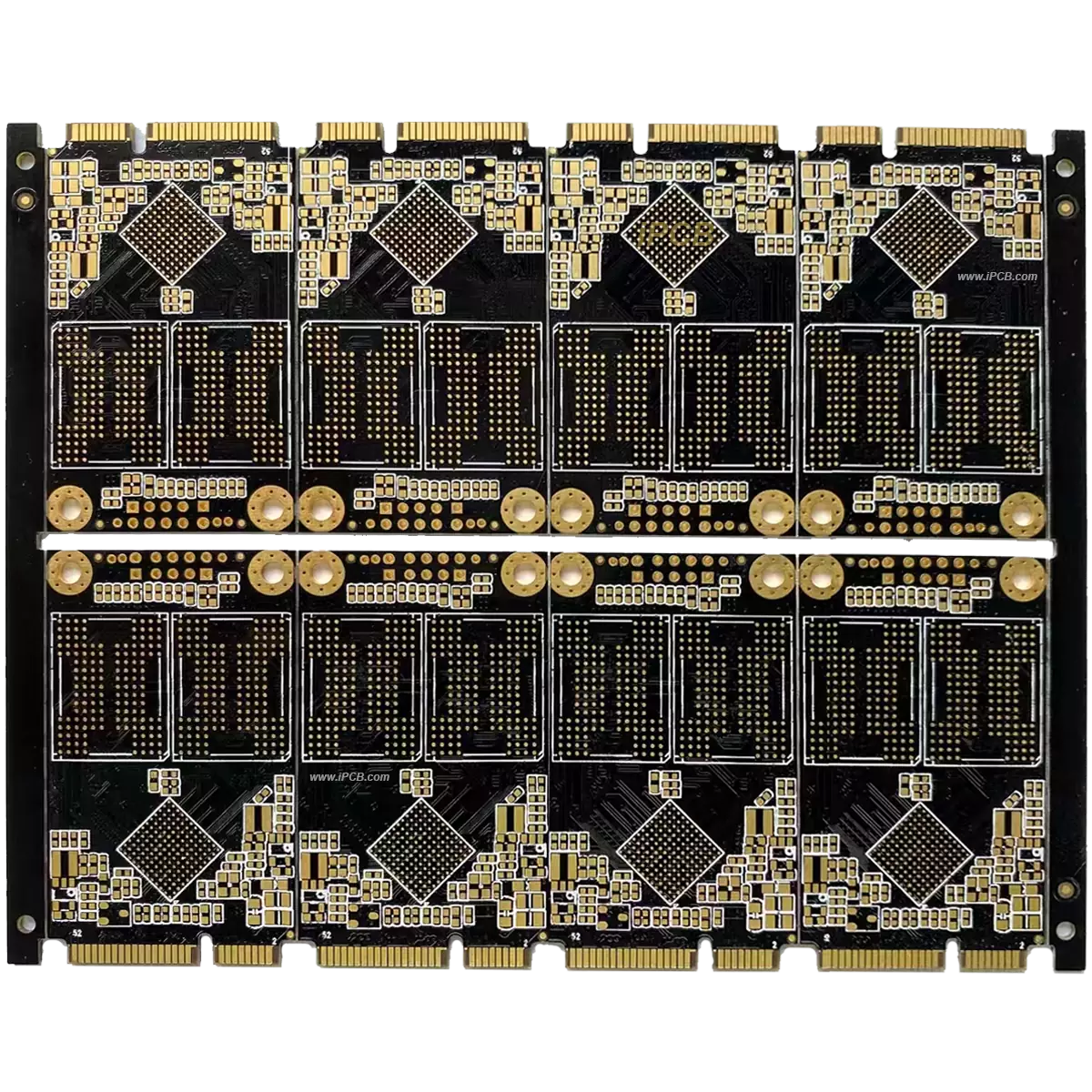

Product Name: Multilayer PCB

Substrate: SY S1000-2

Layer: 6L-8L

Thickness: 1.0mm

Copper plating thickness: 1/H/H/1oz

Surface treatment: immersion gold

Golden Finger: 5u" Gold + 45 degree oblique edge

Minimum line width/spacing: 3/3 mil (75/75 μ m)

Product applications: Solid state drives, storage chips

What is a multilayer PCB? Multilayer PCB refers to a printed circuit board with multiple conductive layers made on a single-layer substrate according to certain design requirements. It achieves high-speed transmission and efficient processing of circuit signals by stacking multiple functional layers together. Common PCB multilayer boards have different layer designs such as 4 layers, 6 layers, 8 layers, and 108 layers.

Multilayer PCB is a circuit board composed of two or more conductive layers (copper layers) stacked on top of each other. The copper layer is bonded together by a resin layer (semi cured sheet). Multilayer PCB is a complex type of printed circuit board. Due to the complexity of the manufacturing process, low production volume, and difficulty in rework, Multilayer PCB price is relatively high.

Multilayer PCB refers to a multilayer circuit board used in electrical products, which uses more single-sided or double-sided PCB boards for wiring. A printed circuit board with one double-sided inner layer, two single-sided outer layers, or two double-sided inner layers and two single-sided outer layers is called a four layer or six layer printed circuit board. The printed circuit board is interconnected by a positioning system and insulation bonding material alternately, and the conductive pattern is designed according to the requirements. It is also known as a multilayer printed circuit board.

With the continuous development of SMT (Surface Mount Technology) and the continuous introduction of new generation SMD (Surface Mount Devices) such as QFP, QFN, CSP, BGA (especially MBGA), electronic products have become more intelligent and miniaturized, thus promoting significant reforms and progress in PCB industry technology. The rapid development of high-density multilayer PCB (SLC) and various high-density interconnect (HDI) microplate technologies has prompted PCB design to gradually move towards multilayer and high-density wiring. Multilayer printed circuit boards are widely used in electronic manufacturing due to their flexible design, stable and reliable electrical performance, and superior economic performance.

The biggest difference between multilayer PCB and single-sided PCB board or double-sided PCB board is the addition of an internal power layer (to maintain the internal electrical layer) and a ground layer. The power and ground networks are mainly wired on the power layer. However, multilayer PCB wiring is mainly based on the top and bottom layers, with intermediate wiring layers as a supplement. Therefore, the design method of multilayer PCB is basically the same as that of double-sided PCB board, and the key is how to optimize the wiring of the inner layer to make the wiring of the circuit board more reasonable and have better electromagnetic compatibility.

The processing of PCB circuit board is generally outsourced, so when providing drawings for outsourcing, it is necessary to be accurate and clear, and to explain as much as possible. Attention should be paid to material selection, lamination sequence, board thickness, tolerance requirements, processing technology, and so on, all of which should be explained clearly. When exporting Gerber files from PCB, it is recommended to use RS274X format for exporting data, as it has the following advantages: CAM system can automatically input data, the entire process does not require manual participation, which can avoid many troubles, while maintaining good consistency and reducing business trips.

The shelf life of multilayer PCB is defined in IPC, and the surface process is anti-oxidation. If the vacuum packaging is not opened, it should be used up within six months. If the vacuum packaging is opened, it should be used up within 24 hours, and in an environment with controlled temperature and humidity, the PCB board should be used up within one year without opening the packaging. If it is opened, it should be pasted up within one week, and temperature and humidity should also be controlled.

The use of multilayer PCB is in professional electronic equipment, especially in situations where the weight and volume are overloaded. However, this can only be achieved by increasing the cost of multilayer PCB in exchange for an increase in space and a reduction in weight. In high-speed circuits, multiple substrates are also very useful as they can provide printed circuit board designers with more than two layers of PCB to lay wires and provide large grounding and power areas.

The function of PCB multilayer circuit board

1. Improve circuit performance: Multilayer PCB can increase signal transmission speed and anti-interference ability by increasing the number of conductive layers, thereby improving the performance of the entire circuit system.

2. Cost reduction: Compared with single-layer circuit boards, multilayer PCB can achieve more compact structural designs, reduce material usage, and thus lower costs.

3. High flexibility: Multi layer PCB can be designed with different functional layers according to actual needs, achieving various circuit functions and having high flexibility.

4. Easy to upgrade: With the continuous updating of product technology, multilayer PCB can be easily upgraded and modified to meet new market demands.

Advantages of PCB multilayer circuit board

1. Improve reliability: Multilayer PCB can effectively reduce signal interference and power noise through reasonable layout and design, improving the reliability of the entire system.

2. Optimize heat dissipation performance: Multilayer PCB can adopt appropriate heat dissipation structure design, effectively improving the heat dissipation performance of the equipment and reducing the failure rate.

3. Easy to maintain: The structural design of multilayer PCB makes fault location easier and the repair process simpler and faster.

4. Improve production efficiency: The production process of multilayer PCB can be highly integrated and standardized through automated equipment, improving production efficiency and reducing production costs.

As the core component of modern electronic devices, multilayer PCB have significant advantages in improving circuit performance, reducing costs, and enhancing reliability. With the rapid development of new technologies such as 5G and the Internet of Things, the demand for multilayer PCB will continue to grow. A deep understanding and mastery of the relevant knowledge and technology of multilayer PCB circuit board is of great significance for the development of electronic manufacturing.

Product Name: Multilayer PCB

Substrate: SY S1000-2

Layer: 6L-8L

Thickness: 1.0mm

Copper plating thickness: 1/H/H/1oz

Surface treatment: immersion gold

Golden Finger: 5u" Gold + 45 degree oblique edge

Minimum line width/spacing: 3/3 mil (75/75 μ m)

Product applications: Solid state drives, storage chips

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.