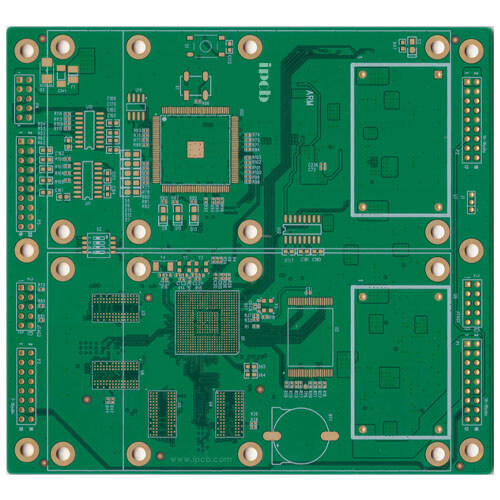

Product: Automotive Electronics 4L PCB

Substrate: Shengyi FR4

Layer: 4L

Finished board thickness: 1. 2mm

Copper board thickness: 1oz (35 μm)

Surface treatment: Innersion gold

Minimum line width/space: 4/4 mil (100 / 100 μ m)

Product application: automotive electronics

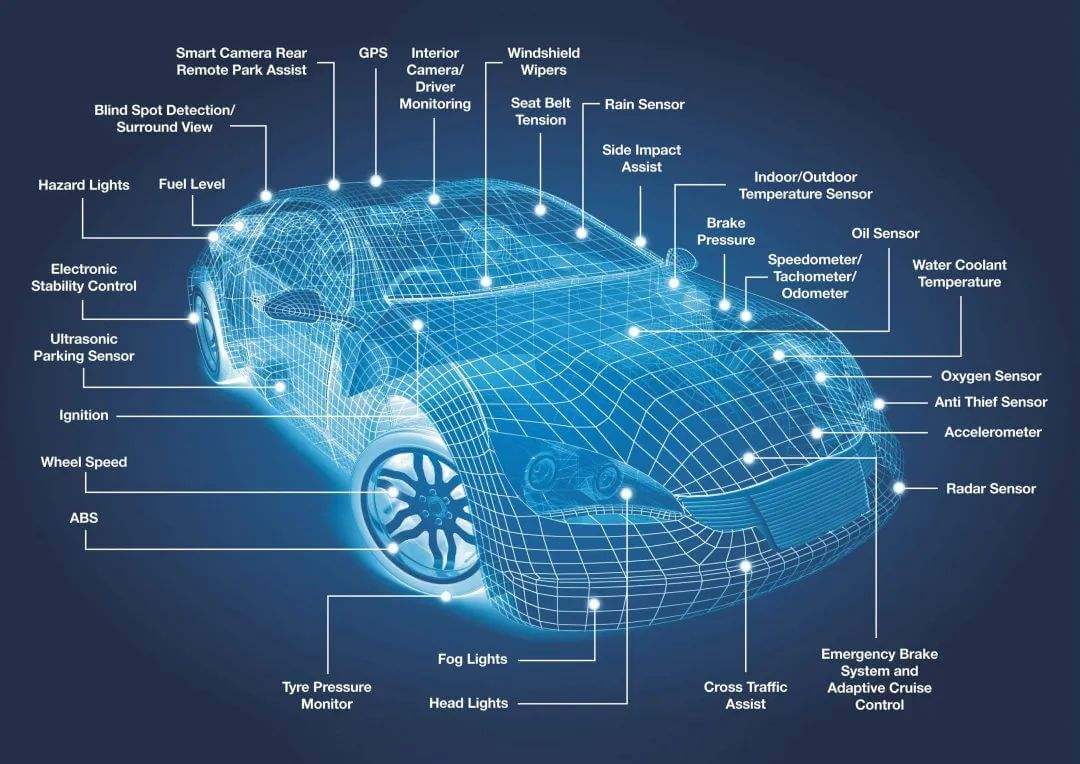

Automotive electronics

The reliability and safety requirements of automobiles are higher, so the threshold for entering the automobile supply chain is higher. Due to the special working environment, safety and high current requirements of automobiles, the reliability and environmental adaptability of PCB circuit boards are very strict. If PCB suppliers want to enter the automotive supply chain, they must pass a series of verification tests, such as ISO/TS 16949 certification. The certification cycle is generally 1-2 years.

iPCB specializes in manufacturing high-end automotive electronic circuit boards. Its products include: microwave radio frequency (RF) PCB, hybrid high-frequency PCB, (1-70 layers) multi-layer PCB, HDI PCB, rigid-flex PCB, metal-based PCB, ceramics PCB. We have in-depth research on PCBs with special requirements such as blind and buried via PCBs, back drilled PCBs, stepped groove PCBs, IC carrier boards, and ultra-thick copper PCBs.

iPCB is an electronic component that uses electronic printing to etch on the surface of an insulating, non-bent copper-clad board, leaving a small circuit network that enables various electronic components to form predetermined circuit connections and implement relay electronic components. transfer function between. PCB is a substrate for assembling electronic parts. It is a key interconnection component of electronic products and a supplier of electrical connections for electronic components. Most electronic devices and products require equipment and are known as the "mother of electronic products". PCB manufacturing quality not only directly affects the reliability of electronic products, but also affects the overall competitiveness of system products.

There are many types of PCB products, generally divided into rigid circuit boards, flexible boards and rigid-flexible boards. In automotive circuit boards automative circuits board, traditional single-layer PCB, double-layer PCB and multi-layer PCB are widely used. In recent years, the wide application of HDI has become the first choice for automotive electronic products.

In the application of automotive electronics, the automotive field is an important application scenario. Due to the multiple components of automotive applications, the scenarios are very rich, including various control systems, audio and video systems, etc. In the future, with the integration and electronicization of vehicles, With the continuous improvement of the level, the demand for use in the automotive field will continue to increase, and more and more reliance will be placed on automotive PCBs. Therefore, high-precision, more advanced boards with higher requirements for environmental anti-interference capabilities will dominate.

The HDI board in the automotive PCB board is highly related to the intelligence of the car. The proportion of market applications in recent years has continued to grow. As well as the characteristics of HDI itself, high precision and small size, following the continuous development of cars, After repeated calculations, HDI is also developing rapidly. The HDI board itself is a circuit board with a relatively high density of circuit distribution using micro-blind buried via technology. Its production requires drilling, metallization in the holes and other processes. Moreover, general HDI boards are manufactured using the build-up method, while high-end HDI uses two or more build-up technologies, as well as advanced PCB technologies such as stacked holes, electroplating, and direct laser drilling. iPCB currently has special processes for 6-level and any-level stacked HDI, as well as mechanical blind and buried via technology, which can ensure product quality when producing high-precision HDI. HDI board is conducive to the use of pre-assembled technology. Its electrical performance and signal accuracy are higher than traditional PCB. Its radio frequency interference, electromagnetic wave interference, electrostatic discharge, heat conduction and other performances are better, making it more suitable for use in the automotive electronics field. .

iPCB continues to improve production technology and quality, and enhance product competitiveness in the manufacturing of HDI circuits board for future automotive electronics.

Product: Automotive Electronics 4L PCB

Substrate: Shengyi FR4

Layer: 4L

Finished board thickness: 1. 2mm

Copper board thickness: 1oz (35 μm)

Surface treatment: Innersion gold

Minimum line width/space: 4/4 mil (100 / 100 μ m)

Product application: automotive electronics

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.