The prevalence of PCB in our daily lives is constantly expanding. To a large extent, this growth is driven by consumer demand for smart products that can monitor or control the more common activities we participate in and industry demands. For example, in the fields of aerospace, medical equipment, automotive, and commercial electronics, industry demands include enhanced functionality and capabilities.

These needs have been met through the utilization and development of new materials, components, and manufacturing technologies. In order to keep up with the following predicted trends, PCB manufacturing processes and equipment must continue to evolve.

Trend 1

High Density Interconnection

The development of high-density interconnect HDI is aimed at meeting the demands of increasingly smaller products with greater functionality, especially in terms of wiring. This feature allows for fewer layers in PCB stacking and promotes high-speed signal transmission. HDI PCB manufacturing faces the challenge of manufacturing wiring in order to route more wiring in a smaller area, which can introduce issues such as noise and interference. The expansion of this concept, including every layer interconnect (ELIC) and any layer interconnect (ALIC), should continue to grow in the coming years.

Trend 2

High power boards (48V and higher)

It has a significant driving effect on higher power PCB. This includes circuit boards with up to 48V power supply. These voltage levels are in response to the growth of solar energy, with solar panels typically operating at 24V or 48V, while the voltage of electric vehicles (EVs) can reach hundreds. These high-power boards require PCB to install larger components such as battery packs, while effectively addressing interference issues.

Trend 3

The Internet of Things (IoT) is a multi-layered design strategy that requires fast communication (usually wireless) between layers and elements. This is the key technology behind smart homes and offices, as well as remote monitoring and control. The main manufacturing challenge of IoT PCB is to meet various standards and regulations that govern their development.

Trend 4

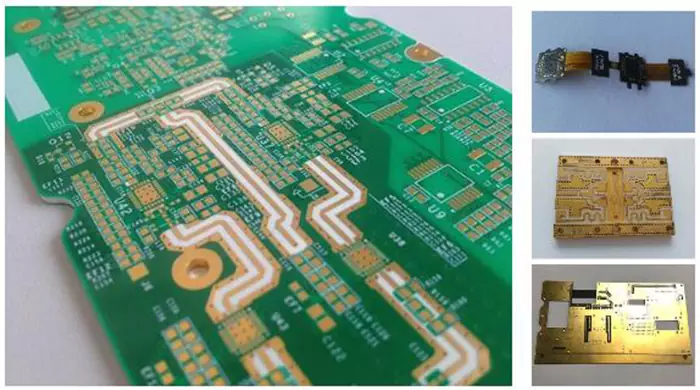

The market share of flexible and rigid flex PCB in PCB development is rapidly increasing. In fact, it is expected that by mid-2020, one-third of all PCB manufactured will be flexible. The advantages of flexible boards include increased capacity, smaller size, higher reliability, and more material choices. However, before selecting materials, you should understand the key properties that affect flexible board manufacturing.

Trend 5

Commercial spot components

Another popular trend is the use of commercial off the shelf or COTS components. The use of COTS components is considered to bring standardization and reliability to components used in critical space-based systems. Traditionally, components used in aerospace manufacturing have been subject to strict scrutiny. However, the commercialization of this industry may lead to reduced regulation of components.

Trend 6

Component Supply Chain Control

The increasing use of electronic products has also stimulated the demand for improving security. The main focus is to eliminate counterfeit components from the supply chain. This is particularly important for critical system manufacturing. Continuously utilizing advanced technology to enhance the ability to solve this problem, including virtual reality (VR) and augmented reality (AR) simulations during PCB assembly.

PCB

The above list represents foreseeable trends in the PCB industry that will have a significant impact on electronic systems and products available to consumers and other end-users in the near future. These trends will drive the sustained development of PCB manufacturing technology in the coming years.

The prospects of the PCB industry are bright, and the future will be even more exciting in terms of product and equipment functionality. However, achieving these aspirations requires continuous development of PCB process technology, techniques, and equipment. There is no circuit board manufacturer better suited to address these challenges than Tempo Automation, a leading PCB prototype and small batch turnkey manufacturer in the industry. Tempo is committed to using cutting-edge software and hardware to ensure that your design goals are met.