At NIO Day 2020 on 9th January 2021, Azera Motors officially unveiled its first intelligent electric flagship sedan, the ET7, which is the first production sedan from Azera and has attracted a lot of attention from the industry. The highlight of the launch was probably the ET7's autonomous driving technology. For the first time, Azera explicitly mentioned in the launch event that it will be able to drive automatically in four scenarios: high speed, urban area, parking, and power switching, and that it will be able to establish a full stack of automatic driving development capabilities.

The configuration of AQUILA is equipped with a variety of high-performance sensing hardware, including: an ultra-long-range high-precision laser radar, five millimetre-wave radars, multiple high-definition cameras, and a variety of other sensing hardware.

Compared to laser radar or cameras, millimetre-wave radar is indispensable for the realisation of various functions in automotive ADAS, thanks to its reliable performance in adverse weather conditions. PCB material is the key material and component in mm-wave radar, and the performance of PCB material determines the performance of mm-wave radar sensors. Rogers' RO3003™ material, with its outstanding performance, is part of the millimetre wave radar solution for the Azera ET7.

Millimetre wave radar sensors are gradually transitioning from 24GHz to 77GHz, with more forward-facing radars and corner radars using 77GHz solutions. For circuit engineers, choosing the right PCB material is crucial to the millimetre wave radar design. In general, when selecting PCB materials, it is necessary to consider choosing thinner PCB materials,better dielectric constant consistency, smaller dielectric loss, etc. At the same time, it is also necessary to consider the material with the time, temperature, humidity and other external working environment, and have reliable electrical performance and mechanical properties.

Dielectric Constant Consistency

In the millimetre wave radar array antenna design, including different types of transmission lines of the circuit structure size, different transmission lines of the phase difference or time delay, as well as the realization of the antenna spacing control of the various units are determined by the dielectric constant of the material. Changes in the dielectric constant within the same board will result in a certain phase difference between the transceiver and the transmitter of an automotive radar, especially a millimetre-wave automotive radar, which will affect the accuracy of vehicle or speed detection and result in a deviation in its positioning. At the same time, changes in the dielectric constant of different batches of materials will cause differences in different millimetre wave radar systems, affecting the consistency of the system. Therefore, the consistency and stability of the dielectric constant of the PCB material used is of paramount importance. At the same time, the dielectric constant (design Dk) of the final circuit is not only related to the process Dk of the material dielectric, but also closely related to the roughness of the copper foil used, the processing of the circuit, and so on. To ensure the phase consistency of the antenna and the performance consistency of the system, the dielectric constant (design Dk) presented in the circuit is more comprehensive and should be taken into account for the evaluation of the actual radar antenna performance.

Roughness of Copper Cladding

It is well known that the surface roughness of the copper foil used in a material has an effect on the dielectric constant of the circuit. Due to the roughness of the surface of the copper foil, the propagation of electromagnetic waves in the circuit is slowed down. Compared to a very smooth surface of the copper foil, this creates a slow-wave effect, which leads to an increase in the dielectric constant of the circuit. The rougher the surface of the copper foil, the higher the dielectric constant of the circuit, while the smoother the surface of the copper foil, the lower the dielectric constant of the circuit.The smoother the copper foil, the better it is for reducing the effect of copper foil roughness on the design Dk, thus helping to maintain consistent circuit performance. For example, Rogers' RO3003G2™ material uses a smoother copper foil with a smaller filler system to further improve the consistency of the dielectric constant and circuit performance.

Temperature-dependent change in dielectric constant (TCDk)

The dielectric constant of a circuit material changes with temperature, and this temperature-dependent parameter helps engineers to understand the possible changes in the properties of a circuit material. The change in dielectric constant with temperature is usually defined as TCDk, and the smaller the change, the more stable the material (at temperature). The TCDk value of an ideal circuit material will remain a fixed Dk value even if the temperature changes, with a TCDk value of 0ppm/°C. In the real world, however, the TCDk value of an ideal circuit material will remain a fixed Dk value even if the temperature changes. However, in the real world, the Dk value changes as the temperature of the circuit material changes. Only circuit materials with very low TCDk values can be considered as materials with temperature-stable Dk, and usually the absolute value of TCDk is less than 50ppm/°C. When an application requires a circuit with a very low TCDk value, the TCDk value is 0ppm/°C. When an application requires a circuit to withstand a wide range of operating temperatures and to maintain stable performance throughout - such as an automotive radar sensor application, which requires consistently accurate measurements and may operate at different operating temperatures - the TCDk parameter of the material is one of the key parameters to be considered.

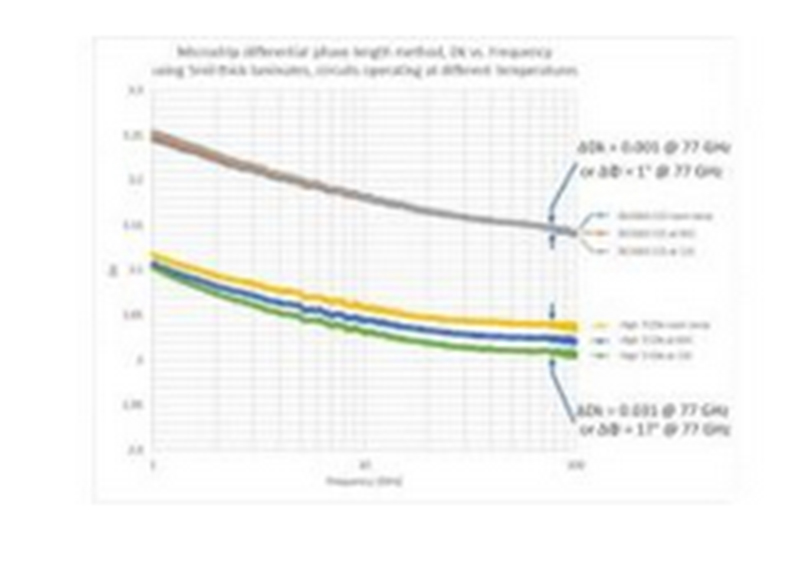

A set of experiments was designed to compare the effects of different TCDk values of high TCDk materials with those of RO3003™. A set of 50Ω microstrip line circuits based on the same design was tested to observe the changes in design Dk and phase at different temperatures. The test results are shown in the figure:

The Rogers RO3003™ material has a very small TCDk value, so there is almost no change in Dk and phase angle of the circuit at 77GHz. The high TCDk material has a Dk change of 0.031 and a phase change of 17 degrees at 77 GHz. When millimetre-wave automotive radar sensors using high TCDk materials are applied in different temperature environments, such high Dk and phase variations will seriously affect the consistency of the system.

Hygroscopicity of materials

The advantage of automotive millimetre wave radar sensors over other types of sensors is that they can operate 24/7 in all types of adverse weather conditions. Therefore, the environment changes not only in temperature, but also in humidity. Design engineers in the selection of circuit materials often ignore the material's moisture absorption, but in fact the material's moisture absorption for circuit performance and system consistency is also critical. Lower hygroscopicity of the material reduces the variation in the dielectric constant and losses of the circuit, thus maintaining almost identical circuit performance and ensuring that the positioning of the radar sensors will not deviate.

The low moisture absorption of Rogers' RO3003™ material is one of the key reasons why it is widely used in 77 GHz automotive millimetre wave radars.

Impact of PCB Manufacturing Process

After the circuit design is completed,it needs to be processed into the radar antenna circuit.The gain of a millimetre wave radar antenna is affected by the insertion loss of the circuit. Different surface treatments of the circuit will have different effects on the circuit.The surface finish of the circuit is essential for PCB circuit board processing,not only to provide a smooth and solderable surface for soldering, but also to protect the copper conductors of the PCB. However, most PCB surface treatment materials are less conductive than copper foil. The lower the conductivity,the higher the conductor loss,and thus the higher the insertion loss of the circuit, especially for millimetre wave circuits. In order to better understand the effect of surface treatment on the loss performance, several sets of transmission lines were processed based on the same circuit material with different surface treatments for loss comparison.

The unique advantages of 77 GHz millimetre wave radar sensors make them indispensable components for self-driving cars. PCB materials determine the performance of millimetre-wave radar sensor antennas, and the selection of materials with stable dielectric constants and low loss characteristics is crucial for the successful design of millimetre-wave radar sensors. In order to achieve stable and consistent circuit performance of the radar sensor, parameters such as the copper foil used in the material and its surface roughness,the variation of the dielectric constant with temperature, and the hygroscopicity of the material need to be taken into account. At the same time, a number of factors during processing also affect the performance of the radar sensor. Overall,good communication with material suppliers and processing engineers at the beginning of the design and during the processing process can improve the performance consistency of the 77GHz millimetre wave radar, increase the yield and reduce the cost.