PCB substrate materials are divided into 94HB, fireproof board (94VO, FR-1, FR-2), half-glass fibre (22F, CEM-1, CEM-3), full glass fibre (FR-4).

FR-1 features 1.halogen-free sheet, conducive to environmental protection, 2.high resistance to leakage trace index (600 volts or more, special requirements need to be made), 3.suitable punching temperature of 40 ~ 70 ℃, 4.bow curvature, distortion rate is small and stable.

FR-2 features 1. superior leakage trace resistance (above 600V), 2. low cost and wide range of use, 3. excellent humidity and heat resistance, 4.suitable punching temperature of 40-70°C, 5.small and stable bow curvature and twist rate, 6. superior dimensional stability.

CEM-3 features 1, excellent machinability, punching processability 1. electrical performance equivalent to FR-4, processing technology is the same as FR-4, the wear rate of the drill bit is smaller than FR-4, 2. multi-level resistance to leakage traces (CTI175V, CTI300V, CTI600V), 3. meets the IPC-4101A specification requirements.

FR-4 features .1 Halogen free substrate, 2. Small and stable bow curvature and twist rate, 3. Excellent dimensional stability.

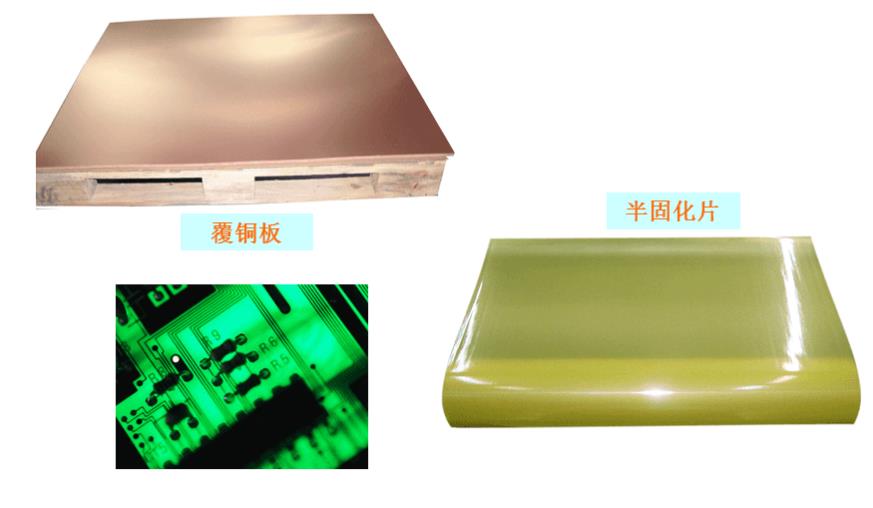

PCB substrate materials

The models of paper-coated copper panels are

KB-3152 FR-1 Material

It is a halogen-free and antimony-free paper-based phenolic resin copper laminate developed for environmental protection, which avoids toxic substances and gases generated by combustion of halogen and antimony contained in the board. It has a high leakage index (over 600 volts) and is suitable for low-temperature punching work.

KB-3151S FR-1 material

It is a paper-based phenolic resin copper laminate developed to meet the needs of precision PCB boards such as high-density automatic inserts and chip part surface adhesion technology. It has excellent resistance to silver migration and electrical performance in humid environments.

KB-3150/KB-3151 Materials

It is a newly developed paper-based phenolic resin copper laminate for the demand of precision PCB boards such as high-density automatic inserts and chip part surface adhesion technology. It has a high leakage index (over 600V) and is suitable for low-temperature punching work.

KB-3150 FR-1 Material

FR-1 is a paper-based phenolic resin insulating laminate developed for precision components such as switch housings (e.g., key switches, push switches). It has excellent flame retardancy and dimensional stability, and is suitable for low-temperature punching work.

KB-2151 FR-2 Material

It is a paper-based phenolic resin laminate with copper surface developed to meet the needs of precision PCBs such as high-density automatic inserts and chip part surface adhesion technology.

KB-2150G/2150GC FR-2

It is an environmentally friendly halogen-free and antimony-free paper-based phenolic resin copper laminate developed for environmental protection, which can avoid the toxic substances and gases generated when burning the halogen and antimony contained in the board. It not only maintains the good performance of FR-2, but also has excellent humidity and heat resistance.

KB-150/1150/150DUnclad (ANSI:XPC)

It is a paper-based phenolic resin insulating laminate developed to meet the needs of precision components for mechanical transmission. It has good resistance to humidity and heat, and is suitable for low-temperature punching work.

kb-1150/kb-1151ansi xpc

Paper-based phenolic resin copper laminates with good resistance to humidity and heat, and suitable for low-temperature punching work.

FR4 Glass Fibre Copper Cladding Sheet Model

Semi-cured sheet FR-4 material

The half-cured sheet is made by curing flame retardant epoxy resin impregnated E-grade glass cloth to "B" stage under precise temperature and weight control, resulting in stable rheological properties during multi-layer PCB fabrication.

KB-7150 CEM-3 Material

A composite-based copper-clad laminate that can be used in place of FR-4 for single/double-sided PCBs, with good processability, reliability of metallised holes, and resistance to humidity and heat.

KB-6167 FR-4 Material

It is an epoxy glass cloth based laminates with excellent heat resistance and mechanical performance. It can be used for PCBs that require high density and excellent heat resistance.

KB-6165 FR-4 Material

Used in computers and peripherals, communication equipment, instruments and meters, office automation equipment, and so on.

KB-6164 FR-4 Material

It is an epoxy glass cloth based laminates with the same performance and UV blocking function as KB-6160, which is suitable for the production of PCBs with UV blocking and AOI function.

KB-6162 FR-4 Material

It is an environmentally friendly glass fibre cloth/epoxy resin based laminates without halogen, antimony, red phosphorus and other toxic ingredients, which is used in computers, computer peripherals, mobile phones, camcorders, TVs, video game consoles, and so on.

KB-6160/6160C FR-4 Material

Epoxy glass cloth based laminates with UV blocking function and other performance equivalent to KB-6150, suitable for PCBs with simultaneous UV and AOI requirements.

KB-6150/6160 FR-4 Material

Used in mobile phones, computers, inspection equipment, VCRs, TVs, military equipment, and guidance systems.

KB-6150/6150C FR-4 Material

It is an epoxy glass cloth based laminates, which can be used as single/double sided PCBs and multi-layer circuits. It has good flame retardancy and dimensional stability.

KB-6050/606X

Suitable for multi-layer PCB pressing.

KB-5152 (GB:22F material)

Used in monitors, video recorders, power supply boards, industrial instruments, digital recorders, etc.

KB-5150 CEM-1 Material

It is a composite copper-clad laminate that combines the good processability of paper substrate with the mechanical and dielectric performance of glass cloth substrate, and is suitable for high-frequency PCBs and PCB board that require punching process.