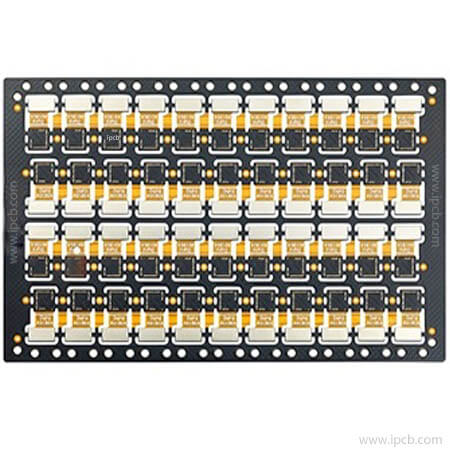

Product name: Photographic lens rigid-flex PCB

Substrate: FR-4+PI

Layer: 4-6L

Finished plate thickness: 0.3-0.4mm

Copper plating thickness: 0.012mm

Surface treatment: NiPdAu

Requirement: The thickness of the 4layer PCB is 0.3mm

Features: Mass production, very low price

Product application: mobile phone camera lens module

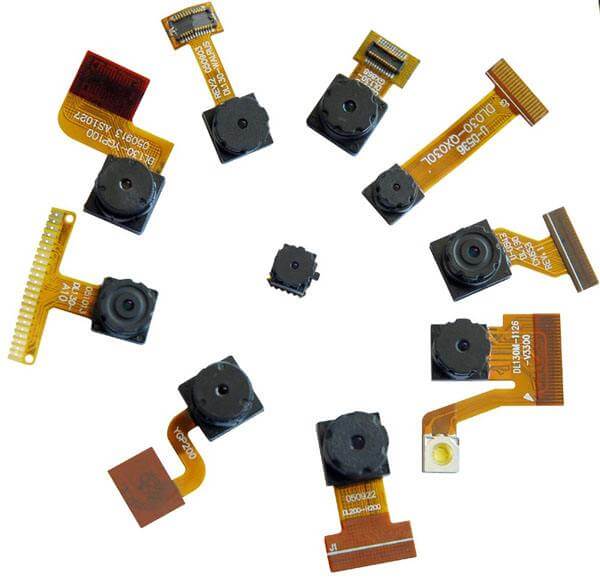

The birth and development of FPC and PCB gave birth to new products of (r-fpcb). Therefore, rigid-flex PCB is a circuit board with FPC characteristics and PCB characteristics, which is formed by rigid-flex PCB according to relevant process requirements.

The rigid-flexible PCB (r-fpcb) used for the camera module must not only meet the ultra-thin, high-flatness functional structure, but also have the unique functions of the rigid-flexible PCB (r-fpcb), flatness The components and chips after pasting can still remain in good condition.

The mobile phone camera module is a complex system that includes multiple components such as lenses, sensors, voice coil motors, and image processors. These components work together to achieve the conversion from light to electricity and image processing.

The performance and quality of the camera module are crucial for the device's ability to take photos and record videos. Different manufacturers and models of equipment may use different camera module configurations, which can affect camera performance, low light conditions, video recording quality, and other related functions. With the continuous advancement and innovation of technology, future mobile phone camera modules will be more advanced and intelligent, bringing us a better photography experience.

Mobile phone camera module

The laser-cut offset detection pads are etched on the circuit board, and there is no copper on the inner and outer layers of the laser-cut path. Two adjacent cameras can share the longest laser cutting line on rigid-flex PCB(r-fpcb). Although the thickness problem is solved through the layout structure, there is no good structure to solve the heat dissipation and strength problems.

Product name: Photographic lens rigid-flex PCB

Substrate: FR-4+PI

Layer: 4-6L

Finished plate thickness: 0.3-0.4mm

Copper plating thickness: 0.012mm

Surface treatment: NiPdAu

Requirement: The thickness of the 4layer PCB is 0.3mm

Features: Mass production, very low price

Product application: mobile phone camera lens module

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.