Radio Frequency Identification (RFID) stands for Radio Frequency Identification.

The principle of radio frequency RFID is non-contact data communication between the reader and the tag to achieve the purpose of identifying the target. The application of RFID is very extensive, with typical applications including animal chips, car chip anti-theft devices, access control, parking lot control, production line automation, and material management. For example, using radio frequency identification (RFID) technology can check the inventory status of goods at any time, track the circulation of goods in real time, upload product data information through RFID tags, and input it into the data management information system for storage, analysis, and processing, easily achieving the purpose of electronic monitoring, data acquisition, logistics control, and product positioning.

Working principle of RF RFID

The basic working principle of RFID technology is not complicated. After the tag enters the reader, it receives the RF signal emitted by the reader, and uses the energy obtained by the induced current to send the product information stored in the chip (Passive Tag, passive tag or passive tag), or the tag actively sends a signal of a certain frequency (Active Tag, active tag or active tag). After the reader reads and decodes the information, it is sent to the central information system for relevant data processing.

A complete RFID system consists of three parts: a reader, an electronic tag, also known as a responder, and an application software system. Its working principle is that the reader emits a specific frequency of radio wave energy to drive the circuit to send out internal data. At this time, the reader sequentially receives and interprets the data, and sends it to the application program for corresponding processing.

From the perspective of communication and energy sensing pipelines between RFID card readers and electronic tags, they can be roughly divided into two types: inductive coupling and backscatter coupling. Generally, low-frequency RFID mostly uses the first type of pipeline, while higher frequency RFID mostly uses the second type of pipeline.

Readers can be reading or reading/writing devices depending on the structure and technology used, serving as RFID system information control and processing centers. Readers typically consist of coupling modules, transceiver modules, control modules, and interface units. The information exchange between the reader and the tag is generally carried out using half duplex communication, while the reader provides energy and timing to the passive tag through coupling. In practical applications, further management functions such as collecting, processing, and remote transmission of object recognition information can be achieved through Ethernet or WLAN.

RF RFID classification

RFID technology can be divided into three categories based on the power supply pipeline of its tags, namely passive RFID, active RFID, and semi-active RFID.

1. Passive RFID.

Among the three types of RFID products, passive RFID appeared earliest, most mature, and has the widest application. In passive RFID, electronic tags exchange information by receiving microwave signals transmitted by RFID readers and obtaining energy through electromagnetic induction coils to briefly power themselves. Due to the elimination of the power supply system, the volume of passive RFID products can reach centimeter level or even smaller, and their own structure is simple, low cost, low failure rate, and long service life. However, as a cost, the effective recognition distance of passive RFID is usually short and is generally used for close range contact recognition. Passive RFID mainly works in lower frequency bands such as 125KHz and 13.56MKHz, and its typical applications include: bus cards, second-generation ID cards, cafeteria meal cards, etc.

2. Active RFID.

The rise of active RFID is not long, but it has played an indispensable role in various fields, especially in the electronic non-stop toll collection system on highways. Active RFID is powered by an external power source and actively sends signals to the RFID reader. Its volume is relatively large. But it also has a longer transmission distance and higher transmission rate as a result. A typical active RFID tag can establish contact with an RFID reader at a distance of 100 meters, with a reading rate of up to 1700 read/sec. Active RFID mainly operates in higher frequency bands such as 900MHz, 2.45GHz, 5.8GHz, and has the function of recognizing multiple tags simultaneously. The long-range and high efficiency of active RFID make it essential in some high-performance and large-scale RFID applications.

3. Semi active RFID.

Passive RFID does not power itself, but the effective recognition distance is too short. The active RFID recognition distance is long enough, but it requires an external power supply and has a large volume. And semi-active RFID is a compromise product for this conflict. Semi active RFID, also known as low-frequency start trigger technology. Under normal circumstances, semi-active RFID products are in a dormant state, only supplying power to the part of the tag that holds data, so the power consumption is relatively low and can be maintained for a long time. After the tag enters the recognition range of the RFID reader, the reader first precisely activates the tag in a small range with a 125KHz low-frequency signal to enter the working state, and then transmits information to it through 2.4GHz microwave. That is to say, first accurately locate using low-frequency signals, and then quickly transmit data using high-frequency signals. Its typical application scenario is to install multiple low-frequency readers at different positions in a large range covered by a high-frequency signal to activate semi-active RFID products. This not only completes the positioning, but also realizes the collection and transmission of information.

Frequency Division of Radio Frequency RFID

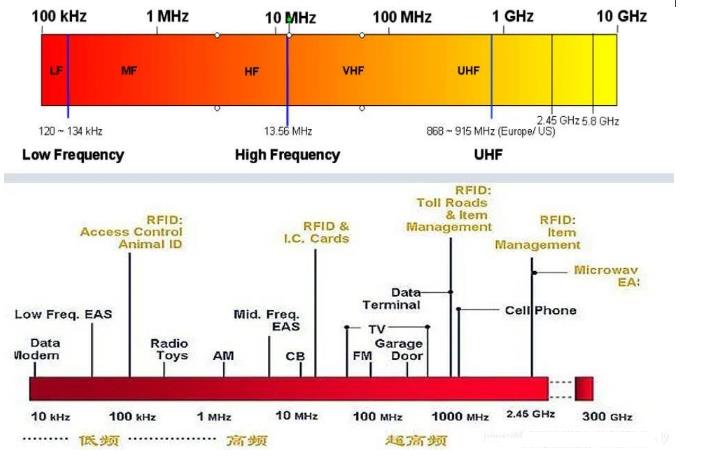

The operating frequencies of RFID products currently defined include low frequency, high frequency, ultra-high frequency (very high frequency), microwave, and other frequency ranges. RFID with different frequency bands have different characteristics. The specific division method is shown in the following figure:

125KHz~134KHz belongs to low frequency

13.56MHz is a high frequency

860MHz~915MHz is ultra-high frequency (very high frequency)

2.4GHz~5.0GHz is microwave

Frequency of Radio Frequency RFID

RFID Low Frequency

RFID low-frequency is mainly used in animal husbandry management systems, car anti-theft and keyless door opening systems, marathon running systems, automatic parking lot charging and vehicle management systems, automatic refueling systems, hotel door lock systems, access control and security management systems. Its characteristics are as follows:

The general operating frequency of sensors working at low frequencies ranges from 120KHz to 134KHz, while TI's operating frequency is 134.2KHz. The wavelength of this frequency band is approximately 2500m. In addition to the influence of metal materials, low frequencies can generally pass through any data object without reducing its reading distance. Readers and writers operating at low frequencies have no special licensing restrictions worldwide. Low frequency products come in different packaging forms. A good packaging form is that the price is too expensive, but it has a service life of more than 10 years. Although the magnetic field area of this frequency decreases rapidly, it can produce a relatively uniform read and write area. Compared to RFID products in other frequency bands, the data transmission rate of this frequency band is relatively slow, and the price of the sensor is relatively expensive compared to other frequency bands

RFID high-frequency

RFID high-frequency is mainly used in the application of library management systems, gas cylinder management, clothing production lines and logistics systems, three meter prepayment systems, hotel door lock management and application, large conference personnel channel systems, fixed asset management systems, pharmaceutical logistics systems, and smart shelf management. Its characteristics are as follows:

The working frequency is 13.56MHz, and the wavelength of this frequency is approximately 22m. Except for metal materials, the wavelength of this frequency can pass through most data, but it often reduces the reading distance. The sensor needs to be kept a certain distance away from the metal. This frequency band is recognized globally and has no special restrictions

Sensors are generally in the form of electronic tags

Although the magnetic field region of this frequency decreases rapidly, it can generate a relatively uniform read and write area. This system has anti-collision characteristics and can read multiple electronic tags at the same time, and write certain data information into the tags

The data transmission rate is faster than low frequency, and the price is not very expensive

RFID ultra-high frequency

RFID ultra-high frequency is mainly applied in supply chain management and application, production line automation management and application, air parcel management and application, container management and application, railway parcel management and application, and logistics management system application. Its characteristics are as follows:

In this frequency band, the global definition is not very consistent. Europe and some parts of Asia define a frequency of 868MHz, North America defines a frequency band between 902 and 905MHz, and Japan recommends a frequency band between 950 and 956. The wavelength of this frequency band is approximately 30cm.

At present, the power output of this frequency band has a unified definition (4W in the United States and 500mW in Europe). The European limit may rise to 2W EIRP.

High frequency radio waves cannot pass through a lot of data, especially suspended particles such as water, dust, and fog. Compared to high-frequency electronic tags, electronic tags in this frequency band do not need to be separated from metals.

The antenna of electronic tags is generally long and tag shaped. Antennas have two designs, linear and circular polarization, to meet the needs of different applications.

This frequency band has a good reading distance, but it is difficult to define the reading area.

Has a high data transmission rate and can read a large number of electronic tags in a short time. 3.4 RFID microwave

RFID microwave 2.4GHz frequency band is mainly used in ship management systems, coal mine personnel positioning systems, dynamic vehicle identification systems, and microcapsule endoscope systems.

RFID microwave 2.4GHz frequency band is a global frequency band, and the development of products has global universality; Its overall bandwidth is higher than other ISM frequency bands, which increases the overall data transmission rate and allows for system coexistence; The volume of 2.4GHz radio and antenna is quite small, and the product size is also smaller

The Development History of RFID

Harry in 1948. Stockman's publication "Communication Using Reflected Power" laid the theoretical foundation for radio frequency identification (RFID). In the mid-20th century, the theoretical and applied research of radio technology was one of the most important achievements in the development of science and technology.

The development of RFID technology can be divided into the following 10-year periods:

1941-1950: The improvement and application of radar gave birth to RFID technology

In 1948, the theoretical foundation of RFID technology was established

1951-1960: The exploration stage of early RFID technology, mainly in laboratory experimental research

1961-1970: The theory of RFID technology developed and some application attempts began

1971-1980: RFID technology and product development were in a period of great development, and various RFID technology tests were accelerated. Some of the earliest RFID applications have emerged

1981-1990: RFID technology and products entered the commercial application stage, and various scale applications began to emerge

From 1991 to 2000, the standardization of RFID technology received increasing attention, RFID products were widely adopted, and RFID products gradually became a part of people's lives

From 2001 to present: Standardization issues have become increasingly important, and the types of RFID products have become more diverse. Active electronic tags, passive electronic tags, and semi passive electronic tags have all been developed, and the cost of electronic tags has been continuously reduced. The scale of application industries has expanded.

The theory of radio frequency RFID technology has been enriched and improved. Single chip electronic tags, multi electronic tag recognition, wireless readable and writable, remote identification of passive electronic tags, and RFID for regulating high-speed moving objects are becoming a reality.