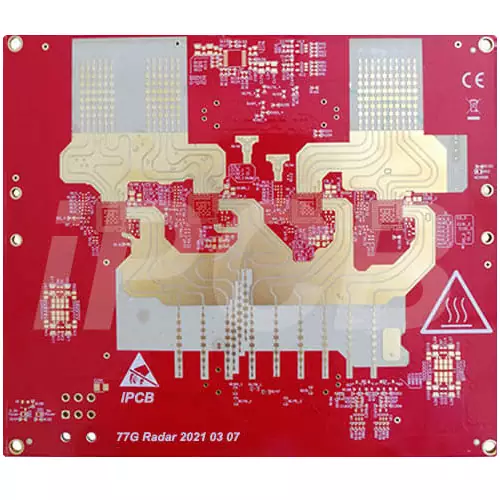

Product: RO3003G2 PCB

Material: RO3003G2+High TG FR-4

Layer: 8Layers

RO3003G2 Dk: 3.0

RO3003G2 medium thickness: 5mil (0.127mm)

RO3003G2 base copper thickness: 0.5oz

Outer copper thickness: 1oz

Finished PCB thickness: 1.2mm

Solder mask colors: Red

Surface treatment: silver or gold

Application: Millimeter wave radar

RO3003G2 is a new generation high-frequency PCB material launched by Rogers specifically to meet the needs of the new generation of millimeter wave automotive radar applications. RO3003G2 is an enhanced version of RO3003.

RO3003G2 ceramic filled polytetrafluoroethylene circuit board material is an extension of Rogers RO3003. The RO3003G2 circuit board material is designed specifically for millimeter wave automotive radar applications based on industry feedback.

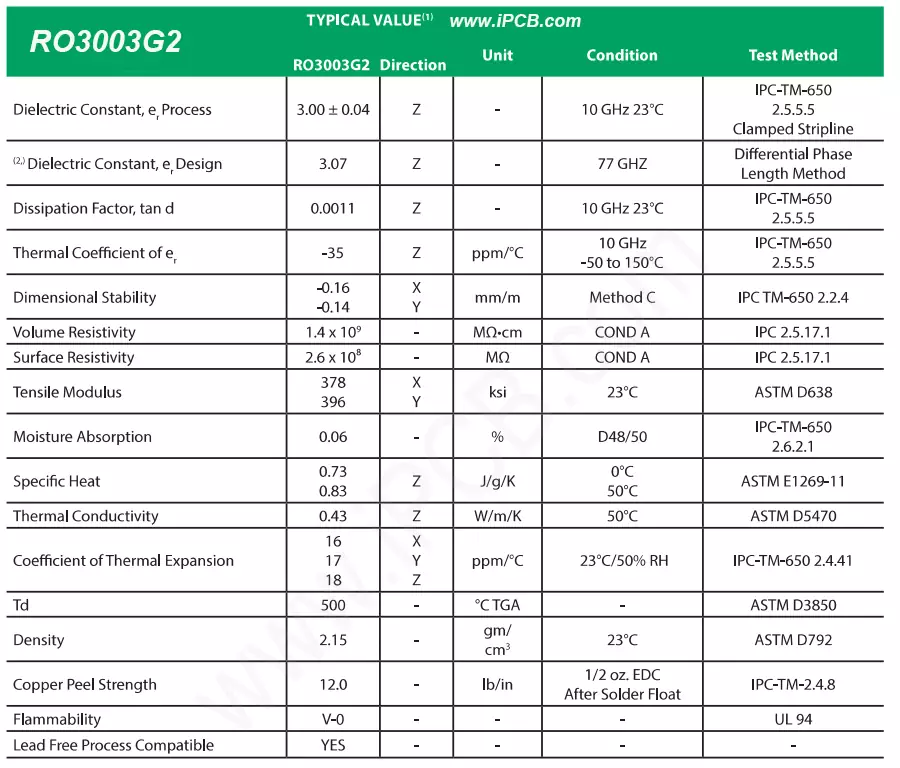

The optimized resin and filler content of RO3003G2, as well as the introduction of extremely low profile ED copper, have been transformed into 3.00@10 GHz (clamped strip line method) and 3.07@77 Dk in GHz (microstrip differential phase length method). These high-frequency PCB material also exhibit very low insertion loss of 1.3dB/inchfor Rogers RO3003G2 5mil, measured by microstrip differential phasor method.

RO3003G2 high-frequency PCB can be used to produce printed circuit board using standard PTFE circuit board processing technology.

Characteristics of Rogers RO3003G2

1. Adopting a brand new electrolytic copper foil material with extremely low roughness (VLP ED) to reduce insertion loss.

2. Combining extremely low roughness electrolytic copper foil material and uniform structure to reduce the dielectric constant changes caused by PCB processing technology.

3. Advanced special fillers with smaller particles are used to design circuits with higher density/smaller diameter micropores.

Rogers RO3003G2 is available in standard sizes: 24 x 18 in. (610 x 457 mm) and 24 x 21 in. (610 x 533.75 mm), respectively, containing 0.5 oz. (18 µ m) or 1.0 oz. (35 µ m) electrolytic copper foil and rolled copper foil. Two types of media thicknesses are available: 0.005 and 0.010 in.

Rogers RO3003G2 application areas: adaptive cruise control, forward collision warning, active braking assistance, lane change assistance, traffic congestion navigation, automatic parking blind spot detection.

Rogers RO3003G2 Datasheet

What is the difference between RO3003G2 vs RO3003?

Millimeter wave radar technology is gradually expanding into civilian fields, such as radar sensors for automotive driving assistance systems. Among them, 77G millimeter wave radar is the mainstream direction for car forward, mainly used for forward collision prevention and automatic cruise control. The frequency of 77G millimeter wave radar has reached the E-band, which has extremely strict requirements for the loss factor and dielectric constant stability of RF circuit board. Rogers developed the RO3003G2 high-frequency laminated board based on the RO3000 series PTFE material, which is suitable for the design of 77G automotive millimeter wave radar.

RO3003G2 uses the optimal polytetrafluoroethylene resin, ceramic fillers, and extremely low roughness electrolytic copper foil. Taking 5ml of RO3003G2 material as an example, the dielectric constant tested at 77GHz frequency is 3.07 and the loss is 1.3dB/inch. Compared to traditional RO3003 material, RO3003G2 is a reinforced version with better dielectric constant stability and loss factor than RO3003.

For example, under the same conditions, the RO3003G2 with a thickness of 5min has a test loss of 1.3dB/inch at 77GHz frequency, while the RO3003 has a loss of 2dB/inch. RO3003G2 adopts a brand new electrolytic copper foil material with extremely low roughness, which reduces conductor loss at high frequencies and can improve the RF performance of 77G automotive radar sensors, such as transmission power and reception sensitivity.

RO3003G2 has lower insertion loss, more stable dielectric constant variation, and an omnidirectional thermal expansion coefficient close to copper. Compared with the previous generation RO3003 PCB, it can provide millimeter wave radar PCB with more performance advantages for 77G automotive radar sensor design engineers.

RO3003G2 adopts the optimal polytetrafluoroethylene resin, ceramic fillers, and extremely low roughness electrolytic copper foil. RO3003G2 further optimizes its performance based on RO3003 and can be regarded as the second-generation RO3003 PCB. The hvlp copper foil used in RO3003G2 is also smoother than ED copper. The insertion losses of RO3003 ED, RO3003G2, and RO3003 RA with a thickness of 5min at 77GHz are 2.0dB/inch, 1.3dB/inch, and 0.9dB/inch, respectively.

iPCB can expedite the production of RF circuit board, mixed high-frequency PCB, special circuit board, microwave RF PCB, microwave antenna PCB and other products. Our inventory material include Rogers RO3533, RO4350, RO4003, RO3003, RO3003G2, RO3006, RT5880 and other models.

Product: RO3003G2 PCB

Material: RO3003G2+High TG FR-4

Layer: 8Layers

RO3003G2 Dk: 3.0

RO3003G2 medium thickness: 5mil (0.127mm)

RO3003G2 base copper thickness: 0.5oz

Outer copper thickness: 1oz

Finished PCB thickness: 1.2mm

Solder mask colors: Red

Surface treatment: silver or gold

Application: Millimeter wave radar

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.