Substrate: Rogers RO4350B high-frequency board PCB

Material: Rogers RO4350B

Dielectric constant: 3.38+/-0.05

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 0.508mm (20mil)

Finished product thickness: 0.6mm

Solder mask color: white

Screen color: Black

Surface treatment: immersion silver

Product application: Communication

Application of RO4350B PCB

Locomotives, rail transit, electricity, renewable energy, body and chassis, lighting, equipment and inverters, defense industrial equipment, onboard, onboard communication, onboard entertainment, vehicle networking, industrial automation, industrial servos, indoor lighting, smart homes, industrial equipment control, mobile phone related, electric vehicle power systems, communication equipment, IoT, warehousing, security systems

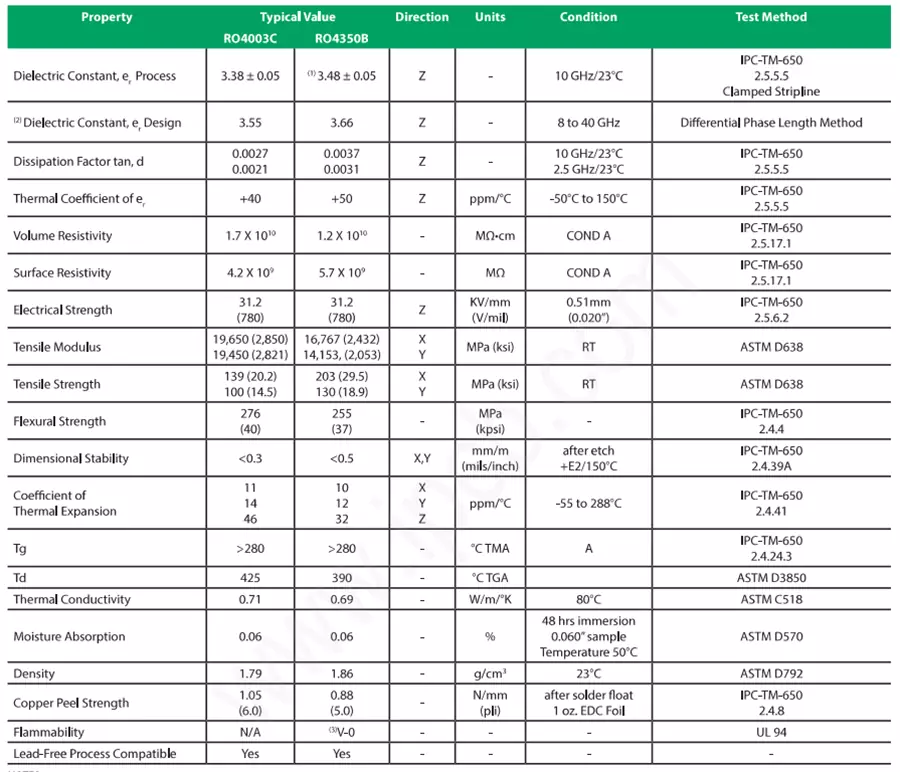

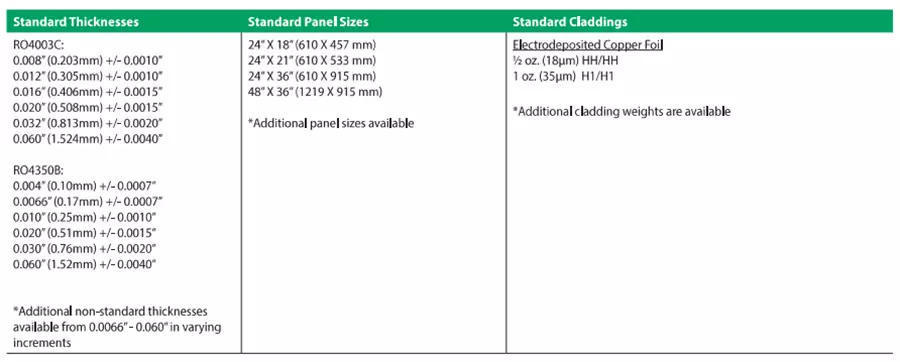

Rogers RO4000 Series DataSheet

The relationship between Rogers RO4350B DK and copper foil roughness and substrate thickness is not fixed and is closely related to the roughness of the copper foil used in the board. For example, the rougher the surface of the copper foil, the greater the effective DK value of the copper-clad laminate, which means that the actual design DK value is larger.

Rogers RO4350B is a low loss material for carbon hydrogen resin and ceramic filler laminates and semi cured sheets, with excellent high-frequency performance (generally applicable below 30GHz). Due to the use of standard epoxy resin/glass (FR-4) processing technology, RO4350B PCB also has low circuit processing costs. It can be said that RO4350B has achieved the optimization of cost and high-frequency performance, and is the most cost-effective low loss high-frequency board.

The reason is that during the propagation of current or electromagnetic waves on the surface of a conductor, if the surface of the conductor is rough, the path taken by the electromagnetic waves becomes longer, equivalent to an increase in DK.

Choose the same rough copper foil, with RO4350B substrate thicknesses of 6.6mil and 30mil respectively

After testing, the average design DK value of the thinner 6.6mil board at 8-40GHz is 3.96

The average design DK value for thicker 30mil sheets at 8-40GHz is 3.68

If a substrate with a thickness of 60mil or more is selected, the design DK value of RO4350B PCB is 3.66. The design DK of high-frequency boards is not fixed and is related to the roughness of the copper foil and the thickness of the substrate. Generally speaking, the rougher the copper foil and thinner the substrate selected for the actual circuit, the larger the design DK of the high-frequency board.

Substrate: Rogers RO4350B high-frequency board PCB

Material: Rogers RO4350B

Dielectric constant: 3.38+/-0.05

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 0.508mm (20mil)

Finished product thickness: 0.6mm

Solder mask color: white

Screen color: Black

Surface treatment: immersion silver

Product application: Communication

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.