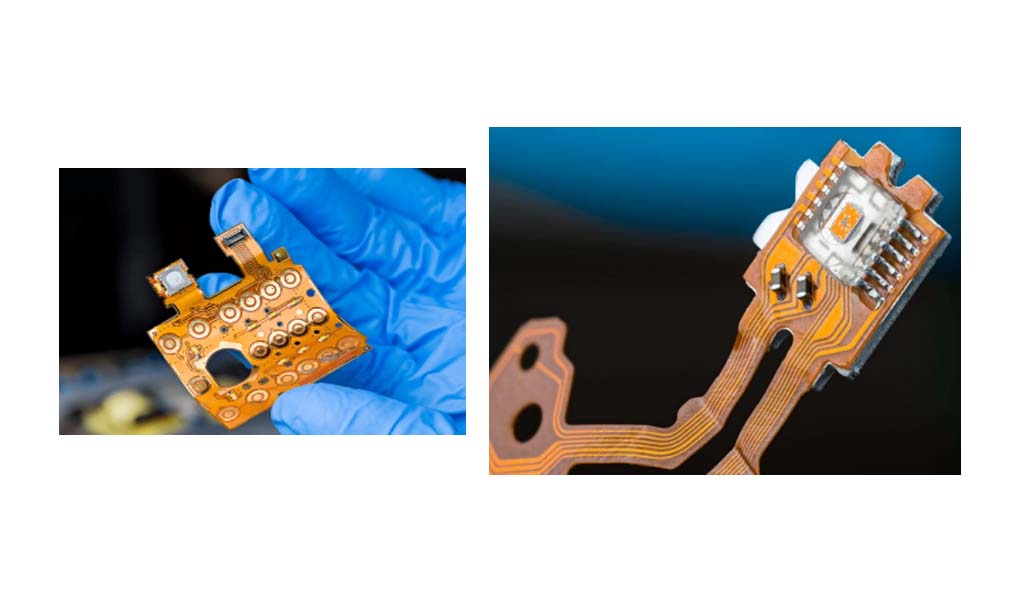

Bendable PCB is a flexible printed circuit board that uses special flexible substrate and conductor materials, which allows it to be bent or folded without affecting performance. Bendable PCB is usually made of materials such as polyester film or polyimide instead of conventional rigid substrate.

Structure:

Substrate

The substrate of Bendable PCB is usually a flexible polymer such as polyimide or polyester. Polyimide is favored for its excellent thermal stability and mechanical properties, while polyester is used for cost-sensitive applications.

Conductive layer

The conductive layer is usually made of copper. Copper is selected for its excellent conductivity and flexibility. Depending on the complexity of the circuit design, the copper layer can be single-sided, double-sided or multi-layer.

Adhesive

The adhesive layer is used to bond the conductive copper layer to the flexible substrate. The adhesive must be flexible and durable to maintain the integrity of the flexible PCB under bending and twisting conditions.

Cover Film

A cover film is a protective layer applied over conductive traces to protect them from environmental factors such as moisture, dust, and mechanical damage. Cover films are often made from the same material as the substrate, such as polyimide.

Key Features and Applications:

Flexibility and Bendability:

Bendable PCBs are often made from flexible plastic substrates such as polyimide, which can be bent or curled without affecting the functionality of the circuit.

This property makes them suitable for applications with space constraints or where device components need to be bent or folded after assembly.

Thin and Durable:

Bendable PCBs are designed to be thinner and lighter, making them suitable for applications that require weight reduction or increased product portability.

Due to the use of flexible materials, they are more durable and can withstand more mechanical stress than traditional rigid PCBs.

Reduced Assembly Time:

Flexible PCBs can often replace multiple rigid PCBs and connectors, reducing the number of components and simplifying the assembly process. This can result in faster production times and lower assembly costs.

Improved Signal Integrity:

Flexible circuit boards can reduce the need for connectors and cables, thereby improving signal integrity by reducing the possibility of signal loss or interference.

Limitations:

Higher initial cost: The initial cost of flexible PCBs may be higher than that of rigid PCBs due to the need for specialized materials and manufacturing processes.

Complex design and manufacturing: Designing and manufacturing flexible PCBs may be more complex than rigid PCBs, requiring specialized knowledge and equipment.

Limited load-bearing capacity: Compared with rigid PCBs, flexible PCBs have limited load-bearing capacity, making them unsuitable for applications that require high mechanical strength.

Application areas:

Consumer electronics: Smartphones, tablets, wearable devices (such as smart watches, health monitoring devices), etc., which often require high-density and flexible circuit design.

Medical devices: Some medical devices require the arrangement of electronic components in limited space, and curved PCBs can meet this demand.

Automotive electronics: More and more sensors and electronic components in automobiles use flexible PCBs to adapt to complex installation spaces.

Industrial and military applications: Some special environments or applications that require durability also use flexible PCBs.

Design and manufacturing:

During the manufacturing process, the substrate used for curved PCBs is generally a flexible polymer (such as polyimide or polyester), and the layout and wiring design of the printed circuit board also needs to adapt to its bending characteristics.

Although bending and folding are possible, special attention needs to be paid to the bending radius and layout during design to ensure that circuit breakage or other problems are not caused during use.

Bendable PCBs provide flexibility and adaptability that traditional rigid PCBs cannot achieve, and are suitable for application scenarios that require the use of electronic components in compact or irregular spaces. They play an important role in modern technology products. With the continuous advancement of technology and the growing demand for smaller, lighter and more flexible electronic products, the use of Bendable PCBs is expected to increase.