HDI high-frequency board is a specialized circuit board with high electromagnetic frequencies, suitable for high frequencies (frequencies greater than 300MHz or wavelengths). Generally speaking, a high-frequency board can be defined as a circuit board with a frequency above 1GHz. The substrate data needs to have excellent electrical properties and good chemical stability. With the increase of power signal frequency, the requirement for substrate loss is very small, so the importance of HDI high-frequency board is emphasized.

What is PCB high-frequency board?

There is a very popular type of PCB circuit board, which is PCB high-frequency board. PCB high-frequency board has always been favored by the market since its invention, and since the emergence of induction heating technology, it has been at the forefront. Its extremely high frequency is active in the communication industry and network technology fields, promoting a set of high-speed information processing systems. It also meets the requirements of many high-precision parameter instruments with its own advantages. So what are the advantages that make this PCB high-frequency board stand so strong.

1. High efficiency

Generally speaking, the consumption of high-frequency circuit boards is due to their low dielectric constant, which naturally results in lower consumption compared to other circuit boards. Under such excellent innate conditions, induction heating technology at the forefront of technological development can also meet the demand for target heating, thereby making the efficiency of high-frequency circuit boards very high. Of course, while pursuing efficiency, we cannot abandon environmental protection.

2. Fast speed

As is well known, the transmission rate is directly proportional to the dielectric constant. In electrical principles, the transmission rate is inversely proportional to the square root of the dielectric constant, meaning that the larger the dielectric constant, the slower the transmission rate; The smaller the dielectric constant, the faster the transmission rate. This is also one of the reasons why PCB high-frequency boards are loved by everyone. It uses special materials that can ensure the characteristic of low dielectric constant, while also ensuring the transmission rate and making the operation of the circuit board relatively stable.

3. High controllability

Widely used in various industries for the heating treatment of precision metal materials, high-frequency circuit boards can not only achieve heating of parts at different depths in their processes, but also focus on heating local characteristics. Whether it is surface or deep level, concentrated or dispersed heating pipelines, they can be easily completed.

4. Strong tolerance

The environment affects the composition of the medium, so high-frequency circuit boards still have requirements for the environment, especially in the south where humid weather is more common. High frequency circuit boards can effectively regulate such environments. High frequency circuit boards made from data with extremely low water absorption can challenge such environments. At the same time, it is best to make PCB circuit boards resistant to chemical corrosion, allowing them to withstand moisture and high temperatures in humid environments, and have great peel strength.

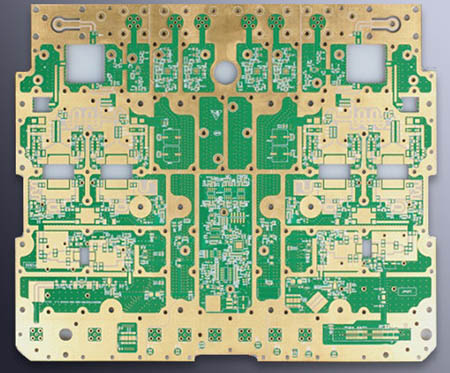

HDI high-frequency board

What is HDI process?

At the same time as electronic products are developing towards lightweight and compact designs, there is a demand for high-density printed circuit boards. HDI (high-density interconnect board) achieves smaller aperture, finer line width, and fewer through holes, saving PCB routing area, significantly increasing component density, and improving RF interference/electromagnetic wave interference/electrostatic discharge.

From the perspective of production technology, ordinary PCBs use the subtractive method, while HDI reduces the minimum line width/spacing to 40 μ m by laser drilling micro through holes and stacking through holes based on the subtractive method; Due to yield issues below 30 μ m, the production process has shifted to semi additive (mSAP) and additive (SAP) methods, involving more copper plating processes. This has significantly increased the required copper plating capacity and increased the demand for exposure equipment (more complex processes) and bonding equipment (increased product layers).

What is the concept of HDI high-frequency board?

HDI high-frequency boards have been widely used in the communication industry, network technology, and high-speed information processing systems, meeting the requirements of many high-precision parameter instruments. Reliable high-frequency circuit boards are of great help to actual production. So what are the advantages of HDI high-frequency board?

High frequency circuit boards with low dielectric constant also have minimal losses. Advanced induction heating technology can meet the target heating requirements with high efficiency. Of course, while emphasizing efficiency, it also has the characteristic of environmental protection, which is very suitable for the development direction of today's society.

The transmission rate is inversely proportional to the square root of the dielectric constant, meaning that the smaller the dielectric constant, the faster the transmission rate. This is the advantage of high-frequency circuit boards. It uses special data to ensure the characteristics of low dielectric constant and stable operation, which is very important for signal transmission.

High frequency circuit boards are widely used in various industries to heat precision metal materials. In its processing field, it can not only achieve heating of components at different depths, but also concentrate heating according to local characteristics. Whether it is surface heating or deep heating, centralized or dispersed heating pipes can be easily completed.

The dielectric constant and dielectric properties have certain environmental requirements, especially in the south where humid weather can seriously affect the use of circuit boards. High frequency circuit boards made from data with extremely low water absorption can challenge this environment. At the same time, it also has the advantages of chemical corrosion resistance, moisture resistance, high temperature resistance, and high peel strength, making HDI high-frequency boards play a powerful role.