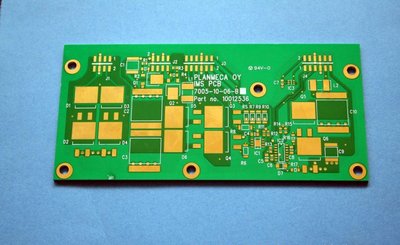

PCB (Printed Circuit Board), is an important electronic component, a support for electronic components, and a carrier for electrical connection of electronic components. Because it is made by electronic printing, it is called a "printed" circuit board.

A double-layer PCB board is a double-layer circuit board. There are wiring on both sides of the double-layer circuit board. However, to use the wires on both sides, there must be appropriate circuit connections between the two sides. This "bridge" between circuits is called a guide hole. A guide hole is a small hole filled or coated with metal on the PCB, which can be connected to the wires on both sides. When drawing a double-sided PCB board with PROTEL, drawing wires on the TopLayer (top layer) to connect components is to draw the board on the top layer; selecting BottomLayer (bottom layer), drawing wires on the bottom layer to connect components is to draw the board on the bottom layer. The above is to draw a double-layer PCB, which means drawing wires on both the top and bottom layers of a PCB board. Double-sided boards solve the difficulty of interlaced wiring in single-sided boards (it can be connected to the other side through holes), that is, there are wiring on both sides, and components can be soldered on the front or the back. It is more suitable for more complex circuits than single-sided boards.

Double layer PCB board -design and wiring principles

The ground wire of the double-layer board is designed to be formed in a grid-like frame, that is, more parallel ground wires are laid on one side of the printed circuit board, and the other side is the vertical ground wire of the copy board, and then they are connected with metalized vias at the intersection (the via resistance should be small).

Considering that a ground wire should be provided near each IC chip, a ground wire is often laid every 1 to 115 cm. Such dense ground wires make the area of the signal loop smaller, which is conducive to reducing radiation. This ground network design method should be before laying signal lines, otherwise it is difficult to achieve.

PCB

Signal line wiring principles of double-layer PCB board

After the reasonable layout of components is determined on the double-layer board, the ground network copy board power line is designed first, and then the important lines-sensitive lines and high-frequency lines are laid, and then the general lines-low-frequency lines are laid. The key leads have independent power supply, ground loop, and the leads are very short, so sometimes a ground line is laid next to the key line close to the signal line to form a working loop.

The wiring principles of the top and bottom surfaces of the four-layer board are the same as the signal lines of the double-layer board. The key crystal, crystal oscillator circuit, clock circuit, CPU and other signal lines are laid first, and the principle of minimizing the circulation area must be followed.

When the printed circuit board IC circuit is working, the circulation area has been mentioned many times before. In fact, it comes from the concept of differential mode radiation. For example, the definition of differential mode radiation: the circuit working current flows in the signal loop, and this signal loop will generate electromagnetic radiation. Since this current is differential mode, the radiation generated by the signal loop is called differential mode radiation. The calculation formula for its radiation field strength is: E1=K1·f2·I·A/γ

Where: E1---The radiation field strength at the space γ of the differential mode copy board printed circuit board can be seen from the differential mode radiation formula. Its radiation field strength is proportional to the operating frequency f2, the circulation area A, and the operating current I. For example, when the operating frequency f is determined, the size of the circulation area is the key factor that can be directly controlled in our design. At the same time, as long as the circulation working speed and current meet the reliability, the larger the better. The narrower the signal jump edge and the lower jump edge, the larger and wider its harmonic component, the higher the electromagnetic radiation, and the larger the power, the larger the current (as mentioned above), which is what we do not expect.

The following are several reference values of the circulation area allowed by logic circuits that can meet the radiation Class B standard. It can be seen that the faster the circuit switching speed, the smaller the allowed area.

If possible, the critical connections can be surrounded by ground wires. After the PCB copy board is routed, all gaps can be covered with ground wires, but it must be noted that these ground wires must be short-circuited with the low-impedance joints of the large ground layer to achieve good results (Note: the gap requirements must meet the conditions, such as creepage distance, etc.).

Double-layer PCB board - wiring skills

It is attractive to use an automatic router to design PCBs. In most cases, automatic routing will not cause problems for purely digital circuits (especially low-frequency signals and low-density circuits). However, when trying to use the automatic routing tools provided by the wiring software to route analog, mixed-signal or high-speed circuits, some problems may occur, and may cause very serious circuit performance problems. [1] There are many things to consider about routing, but the more troublesome issue is the grounding method. If the ground path starts from the upper layer, the ground of each device is connected to the ground wire through the pull wire on that layer. For each device on the lower layer, the ground loop is formed by connecting the through hole on the right side of the circuit board to the upper layer. The immediate red flags that users see when checking the wiring indicate that there are multiple ground loops. In addition, the ground loops on the lower layer are separated by a horizontal line. This can reduce the impact of digital switching δi/δt on analog circuits. However, it should be noted that both double-layer boards have a ground plane on the lower layer of the circuit board. This design allows engineers to quickly see the wiring when troubleshooting, and this method is often seen in demonstration and evaluation boards of device manufacturers. But it is more typical to lay a ground plane on the upper layer of the circuit board to reduce electromagnetic interference (emi).

Double-layer PCB board - design operation steps

Prepare circuit schematic

Create a new PCB file and load the component package library

Plan the circuit board

Load the network table and components

Automatic layout of components

Layout adjustment

Network density analysis

Set wiring rules

Automatic wiring

Manually adjust wiring

Double-layer PCB board PCB design experience (embedded hardware experience)

The clearance spacing is generally 10mil, and 5mil is required for high-density wiring

The wire coming out of the soldering seat should be at least 10mil before changing direction. Do not make the wire diagonally, which will produce sharp angles and look unsightly

The vias of the main power line (with relatively large current) use double holes in parallel to prevent the circuit from failing if one via fails

The power input capacitor uses 100uf and 104 ceramic. The output capacitor capacity should be large enough to meet the circuit requirements (it will not instantly lower the voltage when the current is large). The closer the turn-off diode is to the output pin of the power chip, the better.

The power of the resistor and capacitor of the power supply part should be calculated, and the package should meet the power requirements.

For multiple RF circuits, the RF can be cross-laid on different layers to reduce interference.

Pay attention to the lead position, which must meet the schematic diagram. It is not possible to lead out at any position if the signal is the same.

When routing signal lines with the same characteristics, the signal characteristics should be the same, the routing distance should be as long as possible, and the number of vias should be the same.

Some power supply decoupling capacitors and filter capacitors can be placed on the pins on the reverse side to save space and shorten the wiring distance.

The wiring adopts longitude and latitude wiring, and the upper and lower layers are clearly wired, which can also reduce vias and reduce interference.

When drawing the schematic diagram, the rated current and rated power of the power chip must be strictly calculated to meet the actual load requirements.

When wiring, put the plug-in components around, not in the wiring area, which will cause interlacing and affect the longitude and latitude routing. Prevent interlacing, because the group welding layer of the circuit may be scratched during welding, so adhesion may occur when welding the pins.

It is forbidden to lay copper under the network chip.

When welding, the crystal oscillator must be strictly dropped, because excessive vibration will affect its performance.

The four corners of the PCB board are made into rounded corners to prevent scratches.